A precursor material for lithium ion batteries and a method for manufacturing lithium ion batteries

A lithium-ion battery and precursor technology, which can be used in the manufacture of electrolyte storage batteries, secondary batteries, battery pack components, etc., can solve the problem of high production cost of inorganic solid electrolytes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

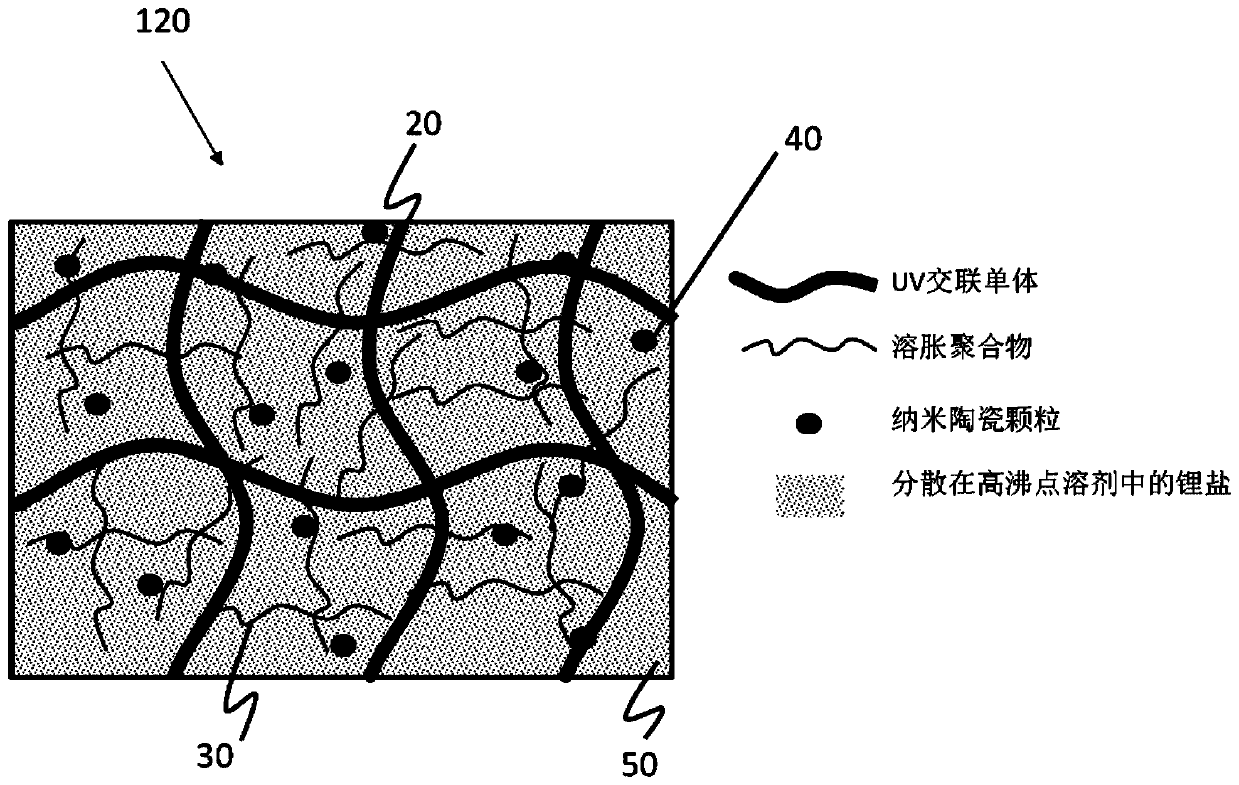

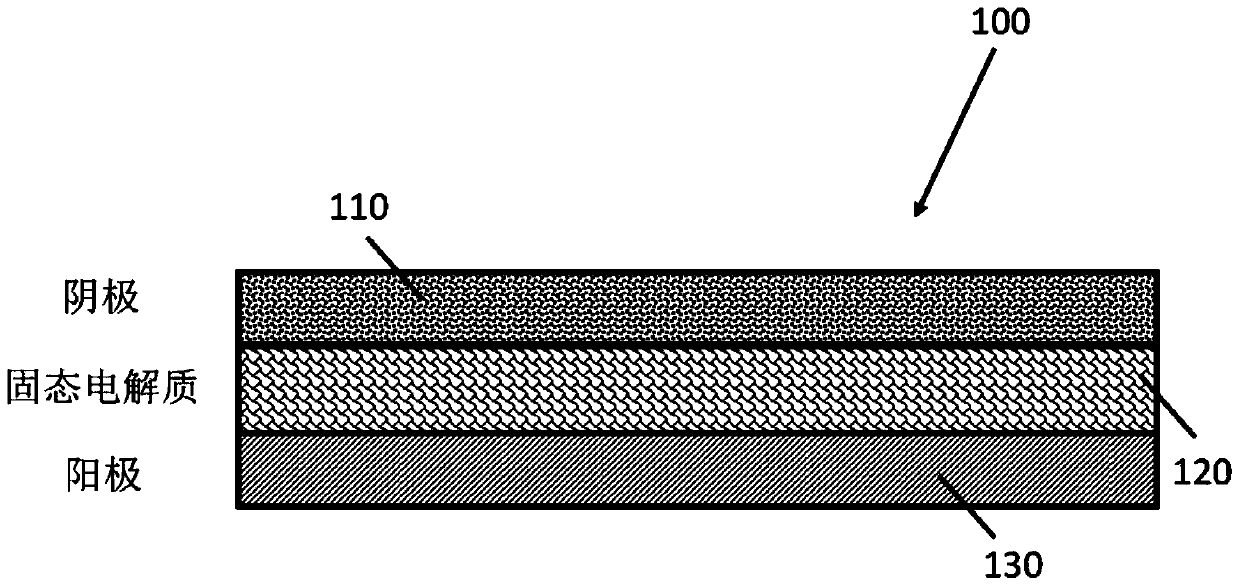

[0027] In order to prepare the precursor material of the solid electrolyte layer, in a mixture of ethylene carbonate (ethylenecarbonate), dimethyl carbonate (dimethyl carbonate), diethyl carbonate (diethyl carbonate) and acetonitrile as an organic solvent, a Lithium hexafluorophosphate (LiPF 6 ) and a 1 M mixture solution of lithium bis(trifluoromethanesulfonimide) (LiTFSI). A mixture of ionically conductive polymers including polyethylene oxide and polyvinylidene fluoride is then dissolved in the solution. Next, 10 wt% of ethoxylated trimethylolpropane as a crosslinkable monomer and 2-hydroxyl-2-methylpropiophenone as a photoinitiator were used at a monomer / photoinitiator weight ratio of 90 10, and 2wt% Al 2 o 3 The nano-ceramic filler is added into the viscous solution, and the defoaming mixer is continuously used for 3 minutes to obtain evenly dispersed ceramic particles. Coat the gel-like precursor onto the electrode. The solid electrolyte was formed by shining UV lig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Ionic conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com