Composite polymer gel electrolyte as well as preparation method and application thereof

A technology of gel electrolyte and composite polymer, which is applied in the direction of composite electrolyte, non-aqueous electrolyte battery, electrolyte immobilization/gelation, etc., can solve the problems of poor mechanical properties and single performance, and achieve high temperature performance and preparation method Simple, leak-reducing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

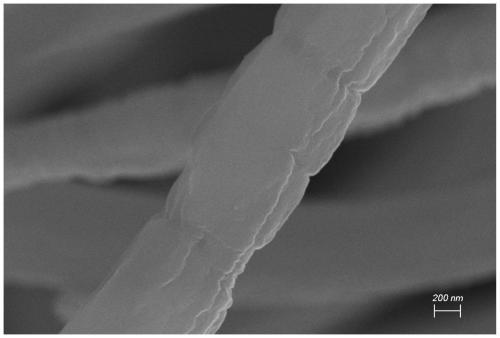

Image

Examples

Embodiment 1

[0024] Preparation of 10wt% PAN / 20wt% APP functionalized polymer gel electrolyte:

[0025] Weigh 1g of PAN powder and dissolve it in 10ml of DMF by heating at 50°C, and heat and stir for 3h. 2.61 g of APP (polymerization degree n=1000) was weighed and dissolved into the above solution to obtain a uniform spinning solution.

[0026] The spinning solution obtained in the previous step is injected into a 20ml syringe, the spinning voltage is 18kV, the injection speed is 1.2ml / h, and the roller receives the spinning film. Put the prepared APAN electrolyte membrane into a vacuum oven to dry to obtain the APAN electrolyte membrane.

[0027] The method for preparing 0.5wt%CNTs / 0.5wt%PAA functional layer:

[0028] Weigh 0.02g PAA, stir at room temperature for 5h, dissolve in 5ml ethanol, weigh 0.02g CNTs, ultrasonically disperse in PAA solution, ultrasonically disperse for 8h to obtain a uniformly dispersed solution, cut the APAN electrolyte film so that it can be completely and eve...

Embodiment 2

[0032] Preparation of 15wt% PAN / 15wt% APP functionalized polymer gel electrolyte:

[0033] Weigh 1.63g of PAN powder and dissolve it in 10ml of DMF by heating at 60°C, and heat and stir the solution for 5h. 1.67 g of APP (polymer n=500) was weighed and dissolved into the above solution to obtain a uniform spinning solution.

[0034] The spinning solution obtained in the previous step is injected into a 20ml syringe, the spinning voltage is 16kV, the injection speed is 1.0ml / h, and the roller receives the spinning film. The prepared APAN electrolyte membrane was dried in a vacuum oven to obtain the APAN electrolyte.

[0035] The method for preparing 0.25wt%CNTs / 0.25wt%PAA functional layer:

[0036] Weigh 0.01g PAA, stir at room temperature for 3h, dissolve in 5ml ethanol, weigh 0.01g CNTs, ultrasonically disperse in the PAA solution, ultrasonically disperse for 2h to obtain a uniformly dispersed solution, and cut the APAN electrolyte film so that it can be completely and even...

Embodiment 3

[0040]Preparation of 20wt% PAN / 10wt% APP functionalized polymer gel electrolyte:

[0041] Weigh 2.37g of PAN powder and dissolve it in 10ml of DMF by heating at 70°C, and heat and stir the solution for 10h. 1.16 g of APP (polymerization degree n=50) was weighed and dissolved into the above solution to obtain a uniform spinning solution.

[0042] Inject the spinning solution obtained in the previous step into a 20ml syringe, the spinning voltage is 15kV, the injection speed is 0.8ml / h, and it is received by an aluminum plate. The prepared APAN electrolyte membrane was dried in a vacuum oven to obtain the APAN electrolyte.

[0043] The method for preparing 0.1wt%CNTs / 0.1wt%PAA functional layer:

[0044] Weigh 0.004g PAA, stir at room temperature for 2 hours, dissolve in 5ml ethanol, weigh 0.004g CNTs, ultrasonically disperse in the PAA solution, ultrasonically disperse for 5 hours to obtain a uniformly dispersed solution, and cut the APAN electrolyte film so that it can be com...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com