Multilayer piezoelectric ceramic actuator and preparation method thereof

A piezoelectric ceramic and actuator technology, which is applied in piezoelectric devices/electrostrictive devices, piezoelectric/electrostrictive/magnetostrictive devices, circuits, etc. Small problems such as avoiding internal stress, prolonging service life and increasing contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0051] The embodiment of the second aspect of the present invention provides a method for preparing a multilayer piezoelectric ceramic actuator, such as Figure 4 to Figure 7 shown, including:

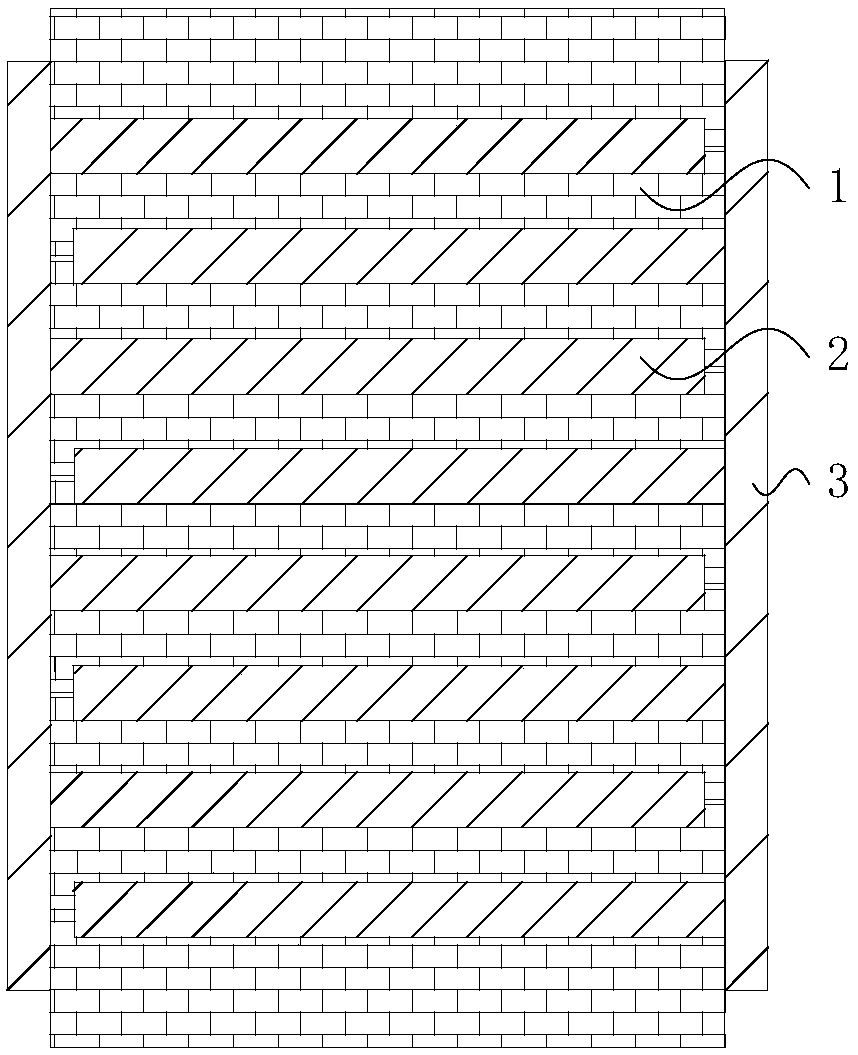

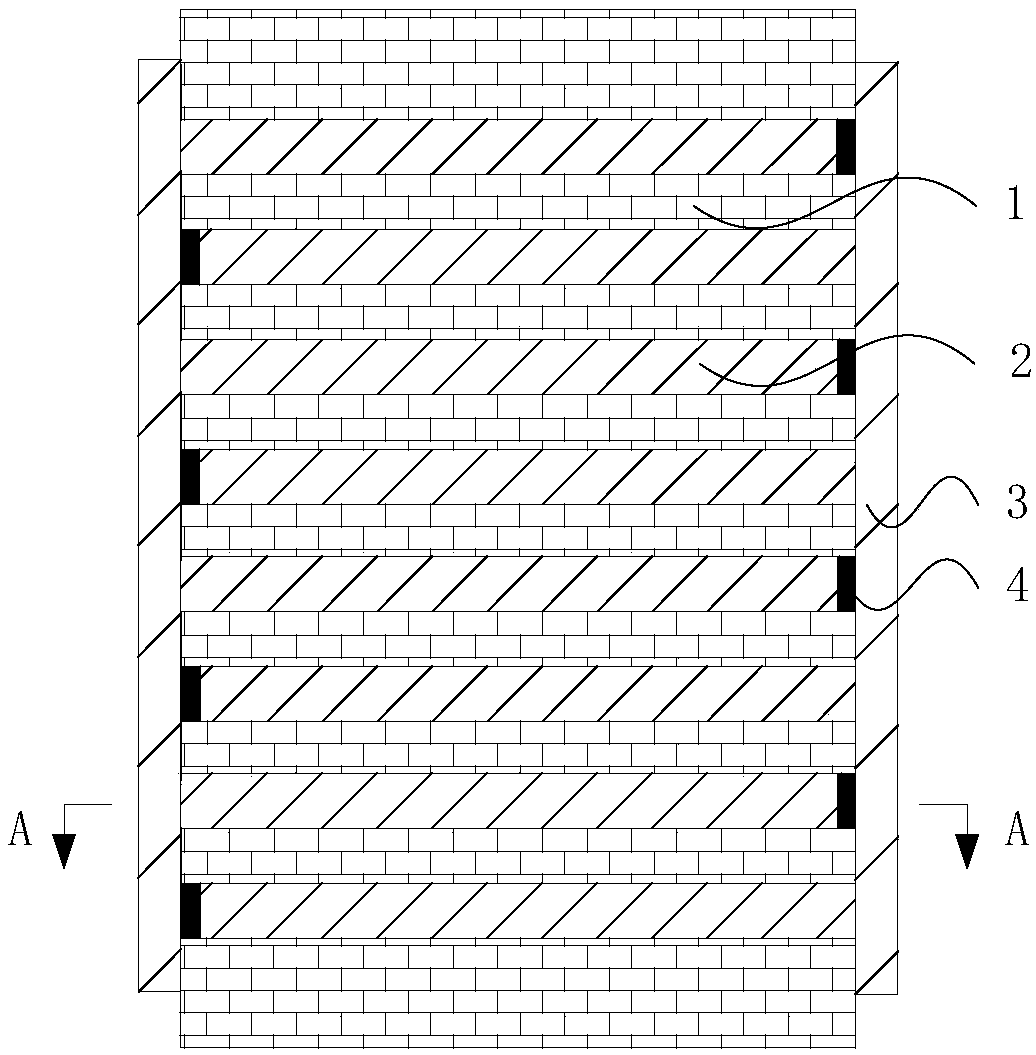

[0052] Step S101, alternately stacking piezoelectric ceramics 1 and internal electrodes 2 to form a full-electrode ceramic stack;

[0053] Step S102, sintering the full-electrode ceramic stack;

[0054] Step S104, alternately etching the edges of a plurality of internal electrodes 2;

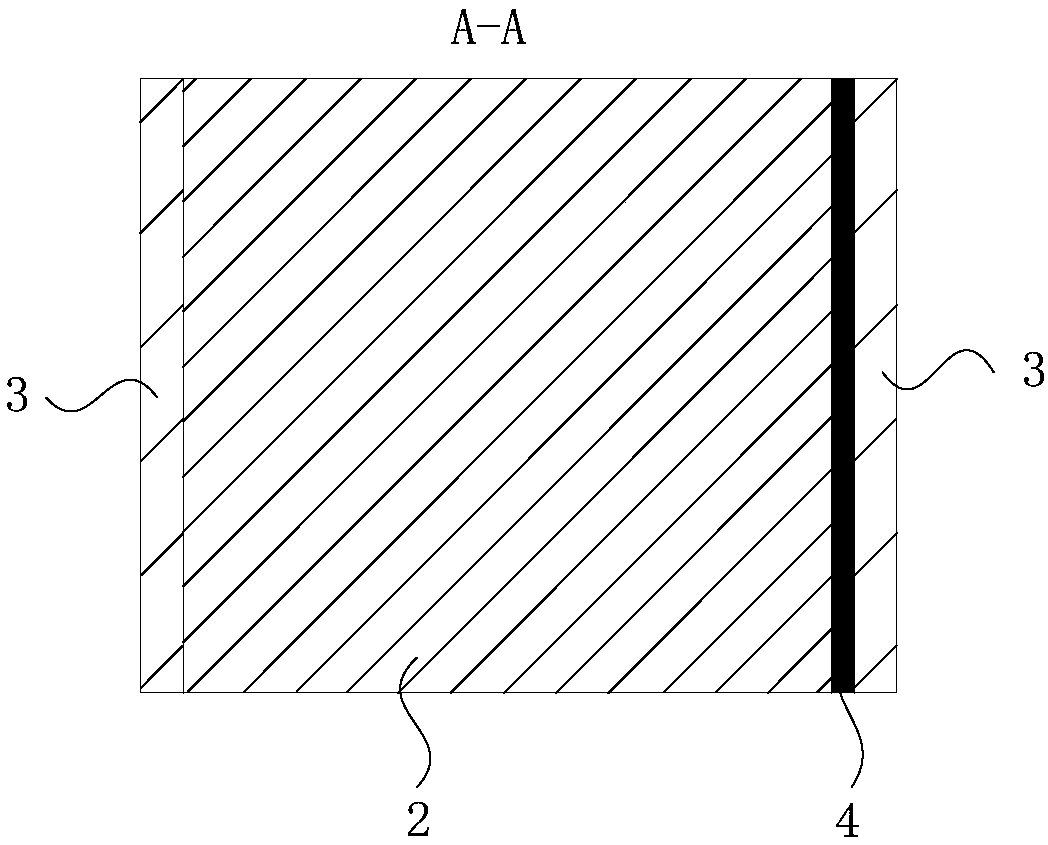

[0055] Step S105, filling the insulating layer to the etching position of the internal electrode 2;

[0056] Step S107, sputtering the external electrodes 3 on both sides of the full-electrode ceramic stack.

[0057] Compared with the prior art, the manufacturing method of the multilayer piezoelectric ceramic actuator provided by the embodiment of the second aspect of the present invention first sinters the alternately stacked piezoelectric ceramics and internal electrodes, and during the sintering pr...

Embodiment 1

[0074] Such as Figure 7 As shown, according to the preparation method of a multilayer piezoelectric ceramic actuator provided by the present invention, comprising:

[0075] Step S101, alternately stacking piezoelectric ceramics 1 and internal electrodes 2 to form a full-electrode ceramic stack;

[0076] Step S102, sintering the full-electrode ceramic stack;

[0077] Step S104, alternately etching the edges of a plurality of internal electrodes 2;

[0078] Step S105, filling the insulating layer to the etching position of the internal electrode 2;

[0079] Step S107, sputtering the external electrodes 3 on both sides of the full-electrode ceramic stack.

[0080] Concrete preparation process is as follows:

[0081]In step S101, the piezoelectric ceramics 1 and the internal electrodes 2 are alternately stacked to form a full-electrode ceramic stack, and the multi-layer piezoelectric ceramics 1 and the internal electrodes 2 are alternately stacked along the vertical direction...

Embodiment 2

[0083] Such as Figure 8 As shown, according to the preparation method of a multilayer piezoelectric ceramic actuator provided by the present invention, comprising:

[0084] Step S1011, printing the internal electrodes 2 onto the upper or lower surface of the piezoelectric ceramic 1 to form stacked subunits;

[0085] Step S1012, stacking a plurality of stacked subunits to form an all-electrode ceramic stack;

[0086] Step S102, sintering the full-electrode ceramic stack;

[0087] Step S103, cooling the sintered all-electrode ceramic stack;

[0088] Step S104, alternately etching the edges of a plurality of internal electrodes 2;

[0089] Step S105, filling the insulating layer to the etching position of the internal electrode 2;

[0090] Step S106, grinding the outer surface of the full-electrode ceramic stack filled with the insulating layer;

[0091] Step S107, sputtering the external electrodes 3 on both sides of the full-electrode ceramic stack.

[0092] The specific...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com