Bobbin dyeing method to prevent dyeing condensation of active turquoise blue dyestuff

A reactive turquoise blue dyeing method technology, applied in the field of textiles, can solve problems such as the inability to effectively avoid color spots, stains, color flowers, troublesome manual operations, and complicated production processes, and achieve the goal of avoiding dye aggregation and color spots. Simple and easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Embodiment 1: a kind of dyeing method utilizing active emerald blue dye dyed cheese, comprises the steps:

[0033] Step 1, using a winding machine (model: SSM-DP) to carry out loose winding of 40 cotton yarns to obtain a spindle-shaped package;

[0034] Wherein, the winding speed of the winding machine is 500-950r / min (preferably 800r / min), the back pressure is 8-15%, the tension is 65-85%, and the winding angle is 11°-14°, preferably 11° , the trimming angle is 15-30°, preferably 25°, the radian of the trimming compensation curve is 0.2-1.6rad, preferably 1.1rad, the compensation ratio is 30-100%, preferably 30%; the package weight is 0.6-0.9kg / piece, the density is 0.44-0.48g / cm 3 ; Package weight is 0.8kg / in the present embodiment;

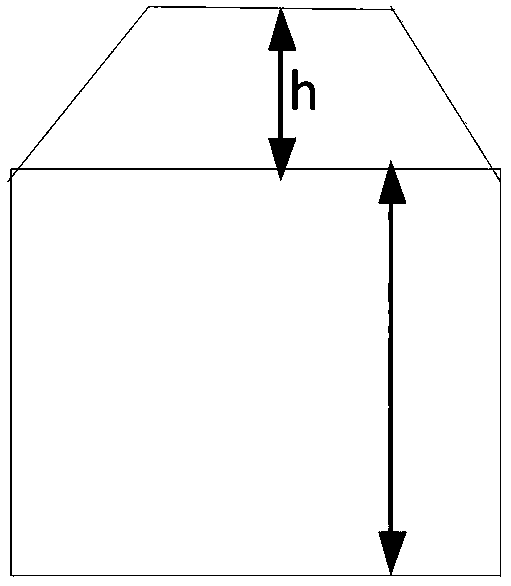

[0035] The spindle shape is that the upper part of the spindle-shaped cheese is truncated cone, the lower part is cylindrical, and the height of the cone is half of the height of the cylinder; the schematic diagram of the spindle-sh...

Embodiment 2

[0048] Embodiment 2: a kind of dyeing method utilizing active emerald blue dye dyed cheese, comprises the steps:

[0049] Step 1, using a winding machine (model: SSM-DP) to carry out loose winding of 40 cotton yarns to obtain a spindle-shaped package;

[0050] Among them, the winding speed of the winding machine is 800r / min, the back pressure is 8%, the tension is 65%, the winding angle is 11°, the edge angle is 15°, the edge compensation curve radian is 0.2rad, the compensation ratio 30%; package weight is 0.6kg / piece, density is 0.44g / cm 3 ;

[0051] The spindle shape is that the upper part of the spindle-shaped cheese is truncated cone, the lower part is cylindrical, and the height of the cone is half of the height of the cylinder; the schematic diagram of the spindle-shaped cheese is as follows figure 1 shown.

[0052] Step 2, pre-dyeing treatment:

[0053] The cheese that step 1 obtains is put into dye vat, carries out water injection to dye vat for the first time; If...

Embodiment 3

[0064] Embodiment 3: a kind of dyeing method utilizing reactive emerald blue dye dyed cheese, comprises the steps:

[0065] Step 1, using a winding machine (model: SSM-DP) to carry out loose winding of 40 cotton yarns to obtain a spindle-shaped package;

[0066] Among them, the winding speed of the winding machine is 950r / min, the back pressure is 15%, the tension is 85%, the winding angle is 14°, the edge angle is 30°, the edge compensation curve radian is 1.6rad, the compensation ratio 100%; cheese weight is 0.9kg / piece, density is 0.48g / cm 3 ;

[0067] The spindle shape is that the upper part of the spindle-shaped cheese is truncated cone, the lower part is cylindrical, and the height of the cone is half of the height of the cylinder; the schematic diagram of the spindle-shaped cheese is as follows figure 1 shown.

[0068] Step 2, pre-dyeing treatment:

[0069] The cheese that step 1 obtains is put into dye vat, carries out water injection to dye vat for the first time;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com