Lignin biological resource utilization method

A biological resource and lignin technology, applied in the field of biochemical industry, can solve the problems of resource waste, environmental pollution, unreasonable utilization of resources, etc., and achieve the effects of improving enzyme activity, improving biodegradation rate and utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] Prepare medium 1 and 3 (the components are shown in Table 1), add the corresponding prepared medium solution into the bioreactor, supplement ultrapure water to a certain volume, and add 1g / L woody For plain straw, the filtered glucose solution was added after the culture medium was sterilized and cooled to room temperature.

[0053] Steam sterilize the prepared bioreactor (maintain at 121°C for 20 minutes). When the temperature drops to 80°C, take it out of the sterilizer and place it in a clean bench to cool. After cooling to room temperature, add the corresponding amount of glucose liquid.

[0054] 10% of the volume of the liquid was inserted into the seed liquid of the chaga to start continuous fermentation, and the fermentation process was maintained at 30°C, 200 rpm, pH 7.0 and ventilation 0.7vvm for continuous cultivation for 20 days.

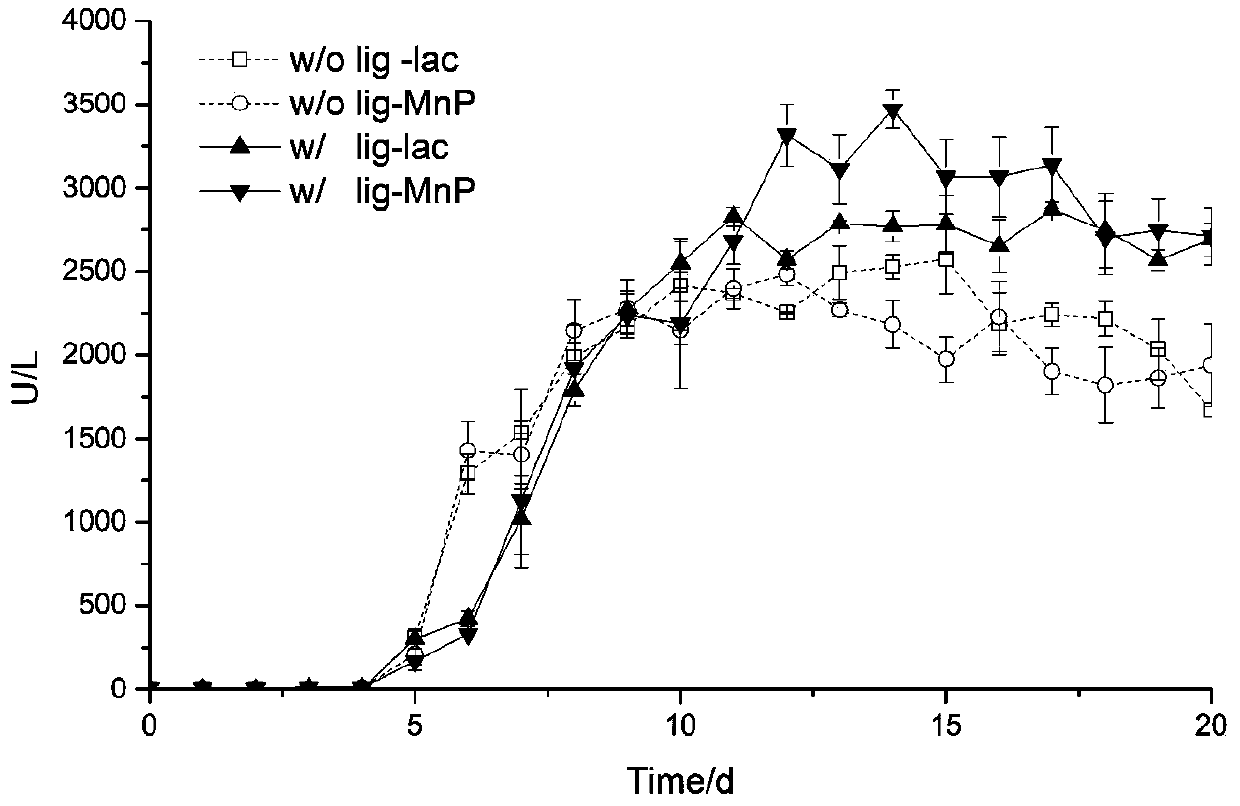

[0055] During the fermentation process, continuous sampling was performed to determine Lac and MnP enzyme activities (see figur...

Embodiment 2

[0057] Prepare culture medium 2 and 3 (see Table 1 for its components), add the corresponding culture medium and trace element solution 2 (see Table 2) into the bioreactor, add ultrapure water to a certain volume, and 1g / L lignin straw was added to some experimental groups, and the filtered glucose solution was added after the culture medium was sterilized and cooled to room temperature.

[0058] Steam sterilize the prepared bioreactor (maintain at 121°C for 20 minutes). When the temperature drops to 80°C, take it out of the sterilizer and place it in a clean bench to cool. After cooling to room temperature, add the corresponding amount of glucose liquid.

[0059] Add Trametes versicolor seed solution according to the volume of 10% of the liquid to start continuous fermentation, keep 35°C during the fermentation process, and continuously cultivate for 20 days under the conditions of 100rpm, pH5.0 and ventilation 0.2vvm.

[0060] During the fermentation process, continuous sam...

Embodiment 3

[0062] Prepare culture medium 3 (see Table 1 for its components), add the corresponding culture medium solution and trace element solution 2 (see Table 2) into the bioreactor, supplement ultrapure water to a certain volume, and in some experiments 1g / L lignin wheat was added to the group, and the filtered glucose solution was added after the culture medium was sterilized and cooled to room temperature.

[0063] Steam sterilize the prepared bioreactor (maintain at 121°C for 20 minutes). When the temperature drops to 80°C, take it out of the sterilizer and place it in a clean bench to cool. After cooling to room temperature, add the corresponding amount of glucose liquid.

[0064] Insert 10% of the volume of the liquid into the mixed seed liquid of chaga and Trametes versicolor (volume ratio 1:1) to start continuous fermentation, and maintain the conditions of 25 ° C, 300 rpm, pH 4.0 and ventilation rate 0.5 vvm during the fermentation process continuous culture for 20 days.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com