Biomass nanofiber diaphragm as well as preparation method and application thereof

A nanofiber membrane and nanofiber technology, which is applied in the field of biomass nanofiber membranes, can solve the problems of reducing the mechanical properties of membranes and loose connection of nanofibers, and achieve the effects of excellent electrochemical performance, high ion migration number and good mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0051] The present invention also provides a kind of preparation method of biomass nanofiber membrane, comprises the following steps:

[0052] S1, providing biomass nanofiber slurry;

[0053] S2. Reacting the biomass nanofiber slurry with a modifier, the modifier being one or more of acrylonitrile and isoacrylonitrile, to obtain biomass nanofibers modified with cyano groups;

[0054] S3. Papermaking the biomass nanofibers modified with cyano groups to obtain a biomass nanofiber separator.

[0055] The biomass nanofiber membrane prepared by the method of the invention has good mechanical properties, and excellent electrochemical properties such as ion conductivity.

[0056] In the embodiment of the present invention, a biomass nanofiber slurry is firstly prepared. Specifically, the biomass nanofiber and dispersion liquid can be mixed and beaten to obtain a biomass nanofiber slurry. The biomass nanofibers can be selected from one or more of cellulose nanofibers and chitin nano...

Embodiment 1

[0067] 1) Disperse 3 g of dried chitin flakes in 1 L of deionized water to obtain a suspension; then add acetic acid solution to adjust the pH value of the resulting suspension to 3, and stir at room temperature for 12 hours. The suspension of 0.3wt.% chitin flakes was ground with a beater at a speed of 20000r / min for 1 hour to obtain chitin nanofiber slurry.

[0068]2) Pour 1L of the resulting chitin nanofiber slurry into a 3L beaker, add 12g of sodium hydroxide, stir evenly, add 2L of acetone, and finally add about 180mL of acrylonitrile to make the concentration of acrylonitrile in the entire mixed solution 1mol / L. (The solvent is acetone, the concentration is 1M), and stirred at room temperature for 5 hours. Then filter and wash twice with acetone and deionized water, respectively, to obtain 3 g of cyano-modified chitin nanofibers (referred to as CCN-1M).

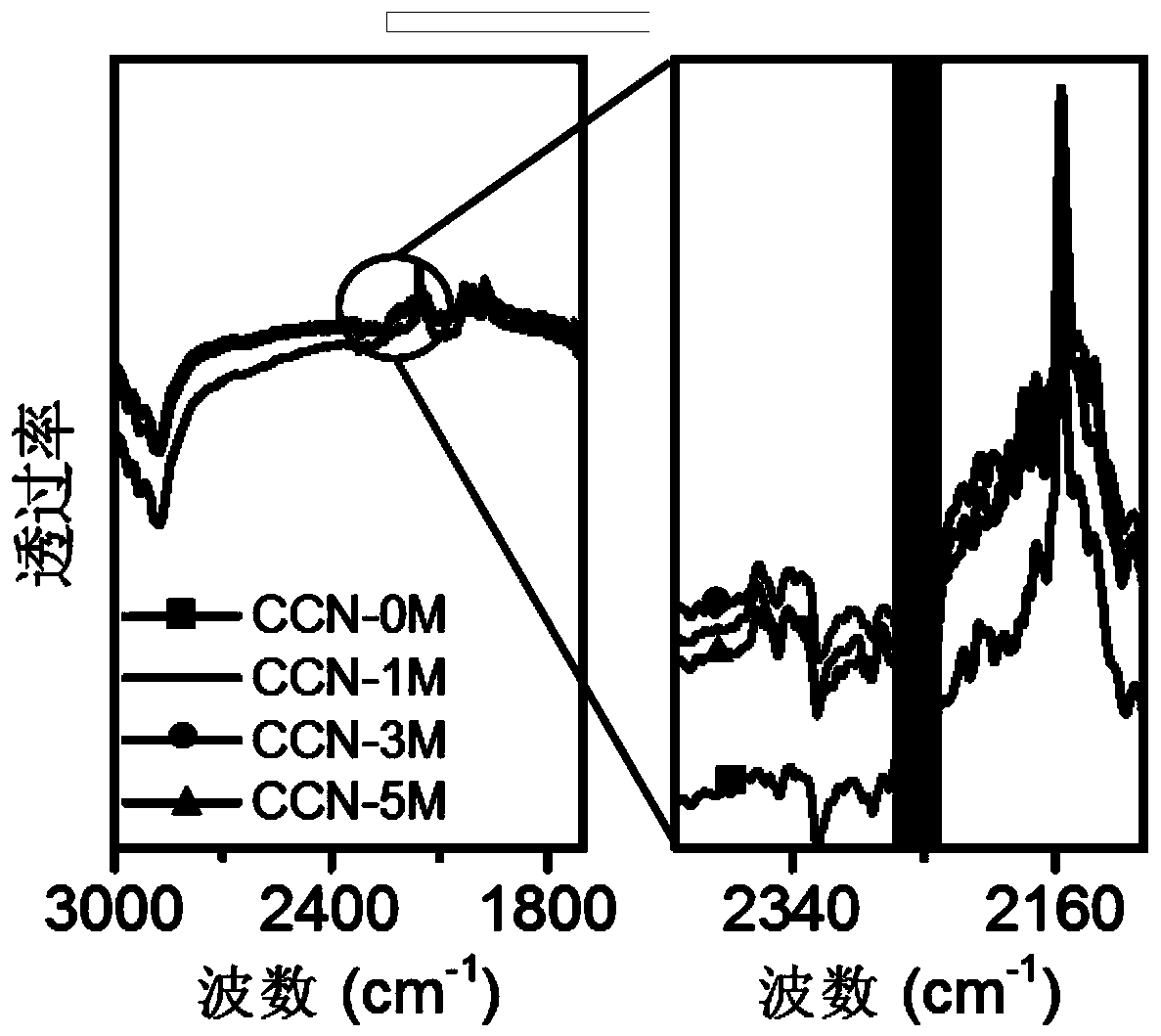

[0069] figure 1 Infrared test graphs of chitin nanofibers modified with different concentrations of cyano groups, ...

Embodiment 2~3

[0076] Prepare according to step 1) and step 2) in Example 1, the difference is that the concentrations of acrylonitrile added in step 2) are 3M and 5M respectively, and cyano-modified chitin nanofibers CCN-3M and CCN are respectively obtained. -5M (cyano substitution degrees are 0.235, 0.234, respectively). Infrared spectrum see figure 1 , after the comparison of the infrared spectra before and after modification, the infrared absorption peak of the cyano group can be clearly seen, which proves that the cyano group is indeed grafted onto the fiber.

[0077] Correspondingly, according to step 3) in Example 1, cyano-modified chitin nanofiber membranes CCN-3M and CCN-5M were respectively prepared.

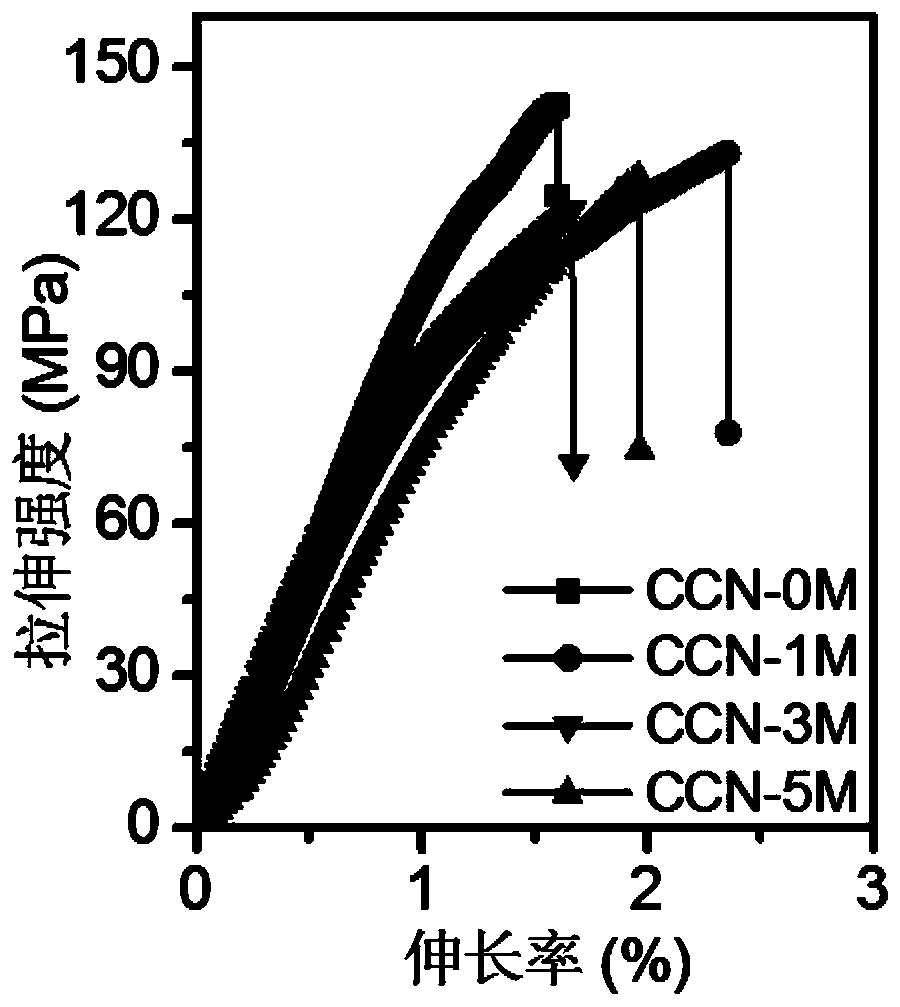

[0078] Carry out performance test according to the test method of embodiment 1, tensile performance test result sees image 3 , the tensile strength of the separators modified with different concentrations of acrylonitrile were all greater than 120MPa. For ionic conductivity test ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com