Thermosetting composition, cured film and display device

A thermosetting and composite technology, applied in nonlinear optics, optics, instruments, etc., can solve the problems of low gas production, flatness, and non-discovery, and achieve excellent low gas production, excellent electrical reliability, and transparency excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0083] Hereinafter, although embodiment of this invention is demonstrated concretely based on an Example and a comparative example, this invention is not limited to these.

Synthetic example 1

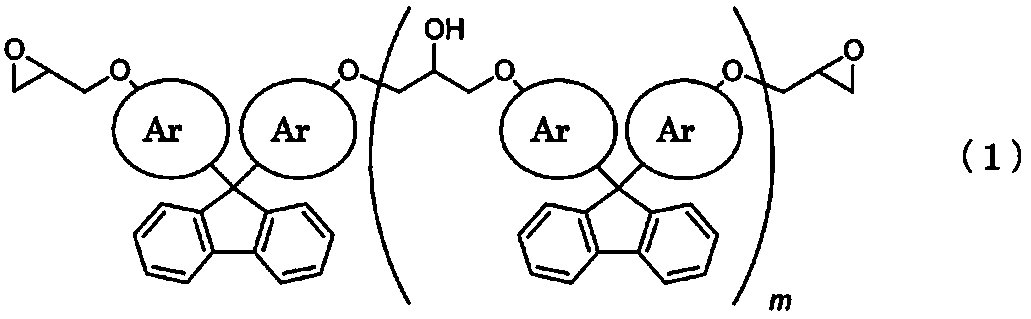

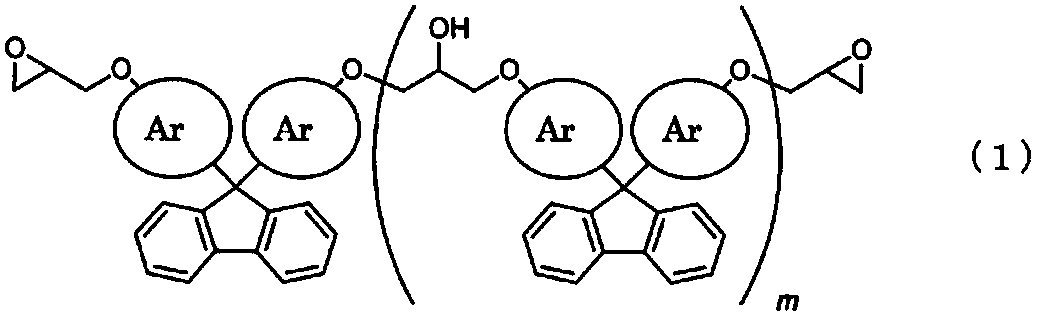

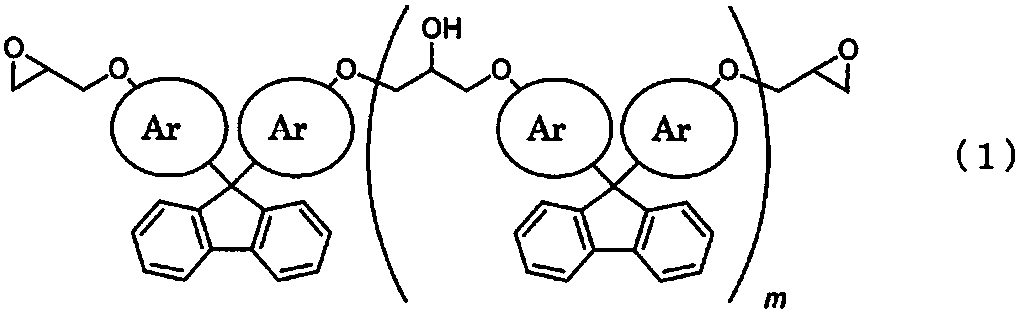

[0085] In the reaction vessel that can carry out decompression reaction with stirring device, condenser, oil-water separation pipe, drop into 9,9-two (4-hydroxynaphthyl) fluorene 451 mass parts, epichlorohydrin 555 mass parts, after dissolving completely, After reducing the pressure in the system to 20 kPa and 73° C., 129.2 parts by mass of a 49% NaOH aqueous solution was added dropwise over 3 hours. During the reaction, the reaction is carried out under the condition of reflux, and the water distilled from the reflux is separated from the epichlorohydrin by using the oil-water separation tube, and the epichlorohydrin is returned to the reaction vessel, and the water is removed to the outside of the system for the reaction. After completion of the reaction, epichlorohydrin was distilled off and dissolved in 600 parts by mass of toluene. After removing the salt generated thereafter and further washing with water, 36.5 parts by mass of a 49% NaOH solution and 14.5 parts by mass ...

Synthetic example 2

[0087] In Synthesis Example 1, 350 parts by mass of 9,9-bis(4-hydroxyphenyl)fluorene was used instead of 451 parts by mass of 9,9-bis(4-hydroxynaphthyl)fluorene. The epoxy compound (A)-2 was obtained by similarly reacting and refining. The epoxy equivalent of the obtained resin was 257 g / eq.

[0088] (Production of Thermosetting Composition)

[0089] It prepared according to the composition shown in Table 1-Table 5, stirred and mixed at room temperature for 3 hours, and dissolved the solid content in the solvent, and produced the thermosetting composition. It describes so that the numerical value of a composition shall be mass parts, and the total of solid content shall be 100 mass parts. In the solid content, there are also components synthesized in the state of being dissolved in the solvent (propylene glycol monomethyl ether acetate) at the beginning. Described as being included in parts by mass of the solvent. The components used in the preparation of the examples are ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy equivalent | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com