Normal temperature and low temperature flammable and explosive medium emptying device

A technology of flammable, explosive and emptying devices, which is applied in the direction of jet propulsion devices, rocket engine devices, machines/engines, etc. It can solve the problems of many dangerous points, fast medium flow rate at the discharge port, and high risk, so as to improve high-altitude stability performance, improving emission safety, and reducing the number of dangerous points

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

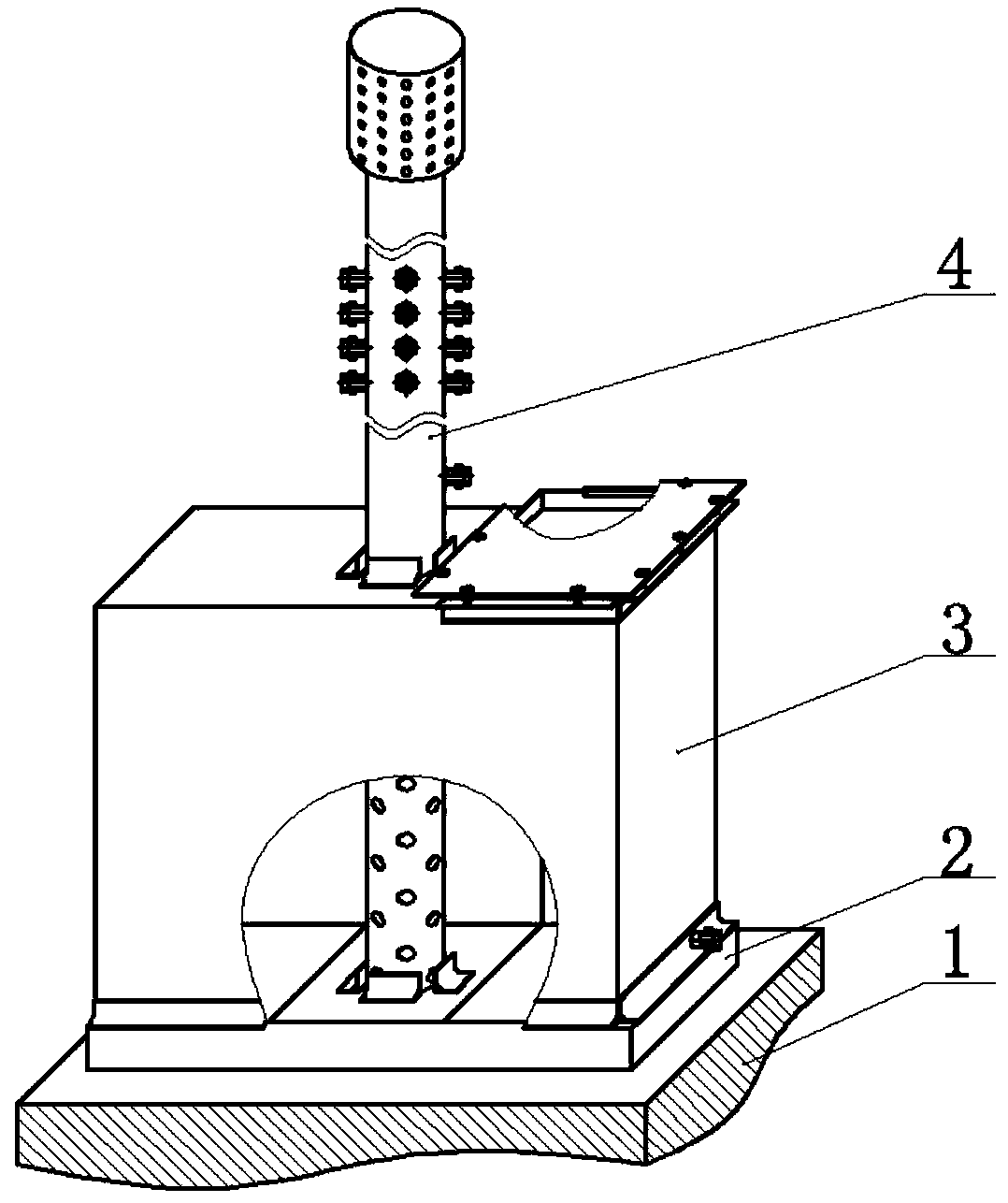

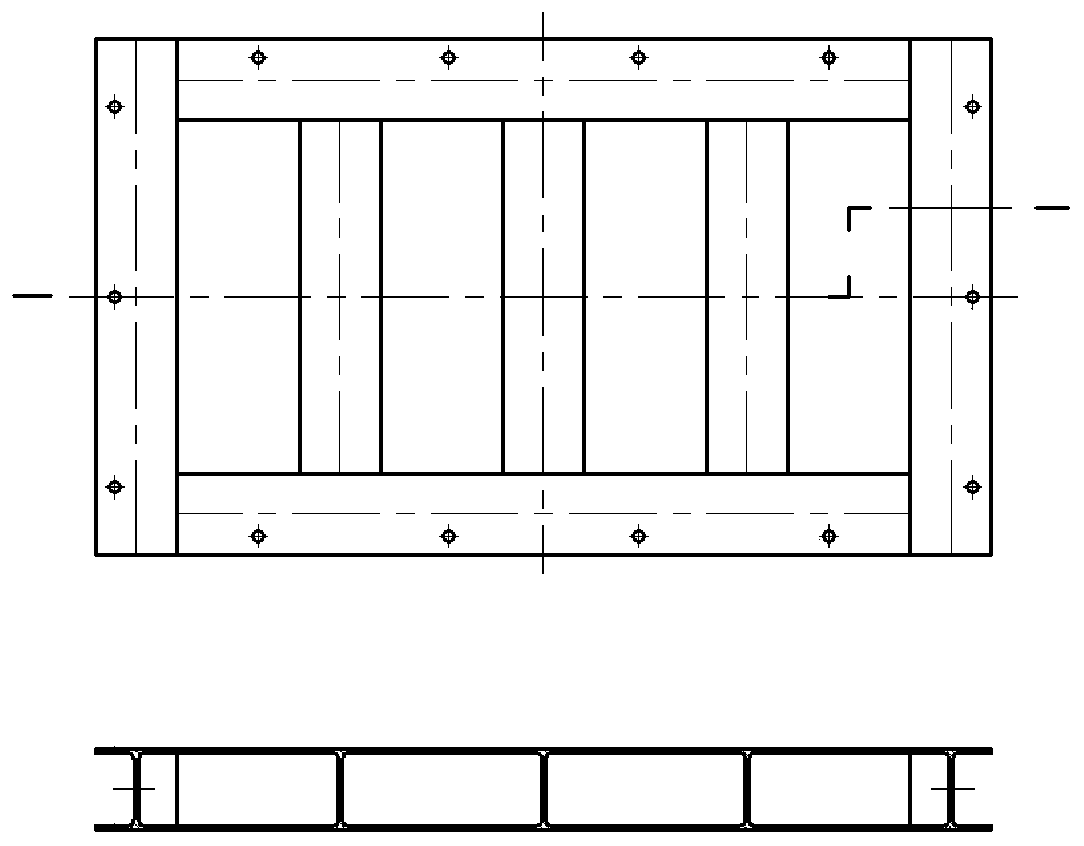

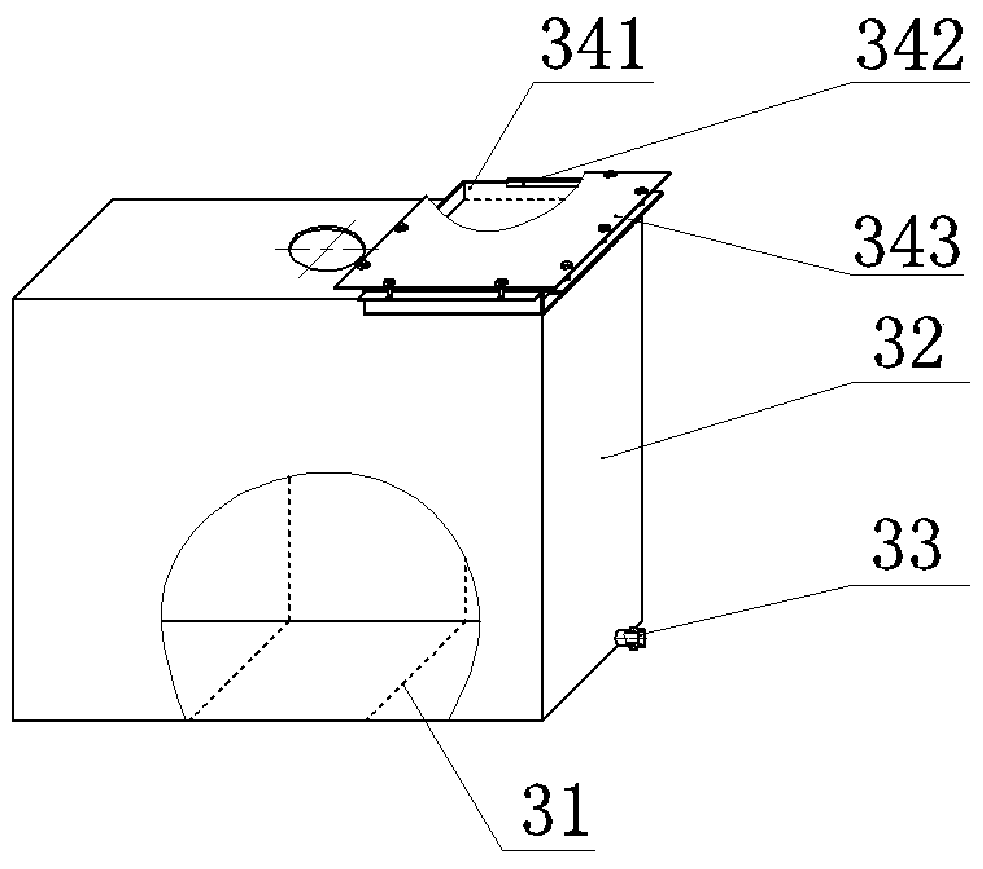

[0020] Such as figure 1 As shown, the normal temperature and low temperature flammable and explosive medium emptying device is composed of a concrete foundation 1, a steel support 2, a collection box 3, and an emptying cylinder assembly 4. The steel support 2 is fixed on the concrete foundation 1, and the collection box 3 Fixed on the steel support 2, the emptying cylinder assembly 4 is fixed on the collection box 3. The concrete foundation 1 can bear the total weight of the shaped steel support 2, the collection box 3, the volume medium in the collection box 3, and the emptying cylinder assembly 4, and has frost resistance. The emptying cylinder assembly 4 is fixed by being inserted into the collection box 3 and bears directly on the bottom of the collection box 3 . The profiled steel support 2, the collection box 3 (except the grooved sealing strip 342), and the emptying cylinder assembly 4 are made of stainless steel. Oxygen or methane that needs to be discharged from eac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com