A high-purity copper matrix graphene composite lithium ion battery and preparation method thereof

A graphene composite and lithium-ion battery technology, which is applied in the manufacture of electrolyte batteries, secondary batteries, battery electrodes, etc., can solve the problems that are difficult to overcome due to the different physical properties of the active layer of the graphene electrode and the current collector, and the insufficient combination of the active material and the current collector. Tightness, reducing electrode cycle charge/discharge life and other issues, to achieve the effect of reducing the internal resistance of the charge transfer interface, improving charge/discharge performance, and increasing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] S100: Mix pure graphene powder with a purity of not less than 99.99% and a fineness of 6000 mesh with lithium cobaltate, lithium manganate and / or lithium iron phosphate at a mass ratio of 1:1, and stir at 90rpm for 45min until they are completely mixed Dissolve as a whole to obtain the primary mixed filler; then add organic solvent, sodium nitrate and potassium permanganate with a fineness of 1500 mesh to each 2 parts of the primary mixed filler according to the mass ratio of 1:1:0.5 and mix them, and mix them through 90rpm and 45min Stir until they are completely dissolved into one another to obtain a graphene mixed filler;

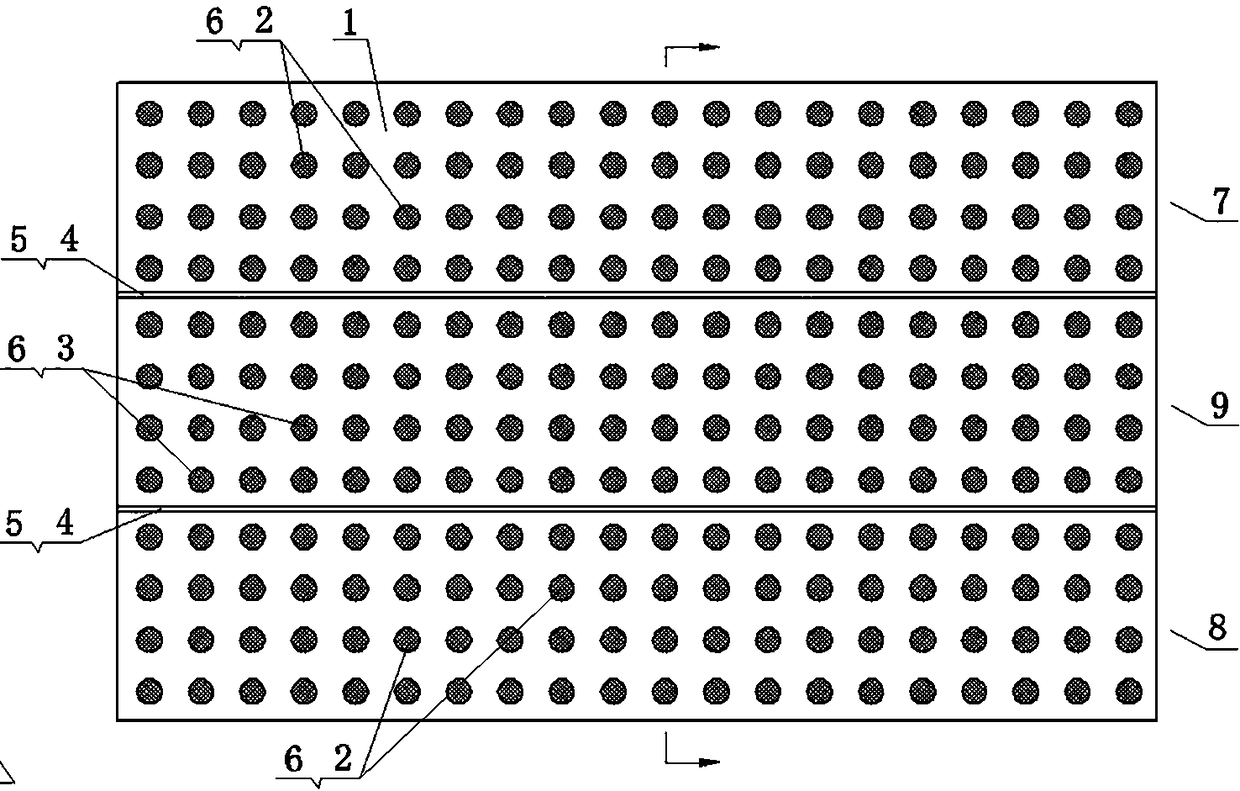

[0047] S200: Divide the surface of the round-hole rectangular high-purity copper mesh with copper purity not less than 99.99% into three parts: left, middle and right, and then open two grooves between the three parts;

[0048] S300: Fill the graphene mixed filler into the left and right meshes of the high-purity copper mesh as the positive and ne...

Embodiment 2

[0053] S50: Put the rectangular high-purity copper mesh with tooth-shaped holes with a copper purity of not less than 99.99% in sequentially placed in 5% FeCl 3 and HCl dilute solution for 20min, then placed in Ar / H 2 Annealing treatment under atmosphere for 30min, annealing temperature 1000℃;

[0054] S100: Mix pure graphene powder with a purity of not less than 99.99% and a fineness of 10,000 mesh with lithium cobaltate, lithium manganate and / or lithium iron phosphate at a mass ratio of 1.5:0.5, and stir at 60rpm for 60min until they are completely Dissolve as one to obtain the primary mixed filler; then add organic solvent, sodium nitrate and potassium permanganate with a fineness of 1200 meshes to each 2 parts of the primary mixed filler according to the mass ratio of 1.5:1.5:0.2, and mix them through 120rpm, 30min Stir until they are completely dissolved into one another to obtain a graphene mixed filler;

[0055] S200: Divide the surface of the rectangular high-purity ...

Embodiment 3

[0061] S50: Soak the rectangular high-purity copper mesh with tooth-shaped holes with a copper purity of not less than 99.99% in a dilute solution of 5% FeCl3 and HCl for 10 minutes, and then place it in an N2 atmosphere for annealing treatment for 50 minutes at an annealing temperature of 800°C ;

[0062] S100: Mix pure graphene powder with a purity of not less than 99.99% and a fineness of 12,000 mesh with lithium cobaltate, lithium manganate and / or lithium iron phosphate at a mass ratio of 0.5:1, and stir at 120rpm for 30min until they are completely Dissolve as a whole to obtain the primary mixed filler; then add organic solvent, sodium nitrate with a fineness of 2000 mesh and potassium permanganate to each 2 parts of the primary mixed filler according to the mass ratio of 0.5:0.7:0.7 and mix them. After 100rpm, 40min Stir until they are completely dissolved into one another to obtain a graphene mixed filler;

[0063] S200: Divide the surface of the rectangular high-purit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com