Distributed type power generation and hydrogen generation system based on sewage treatment plant

A technology for sewage treatment plant and distributed power generation, which is applied in hydrogen separation, electrolysis process, electrolysis components, etc. It can solve the problems of high hydrogen price and large industrial power consumption, so as to reduce the cost of hydrogen production, efficiently utilize and promote large-scale production. effect of development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

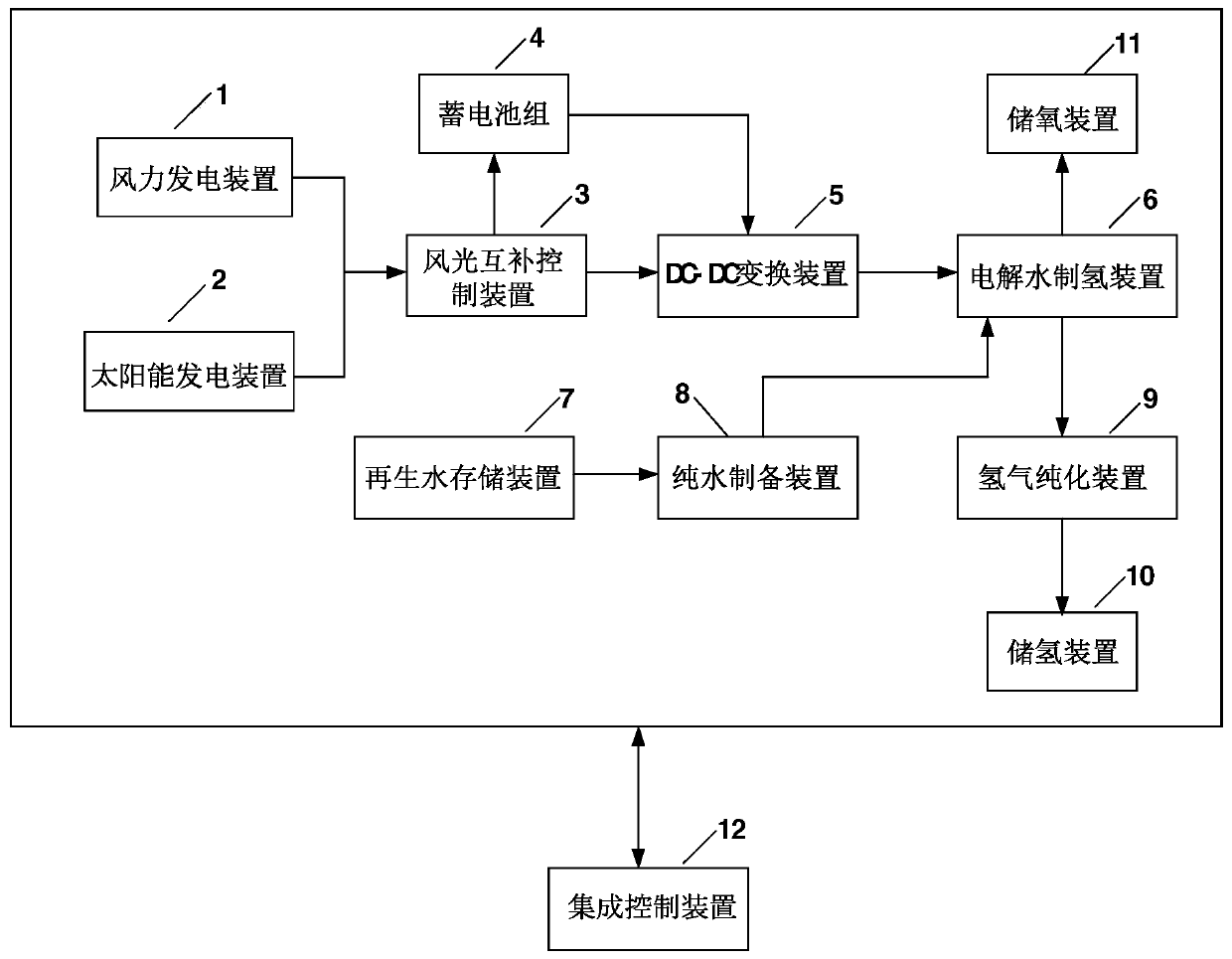

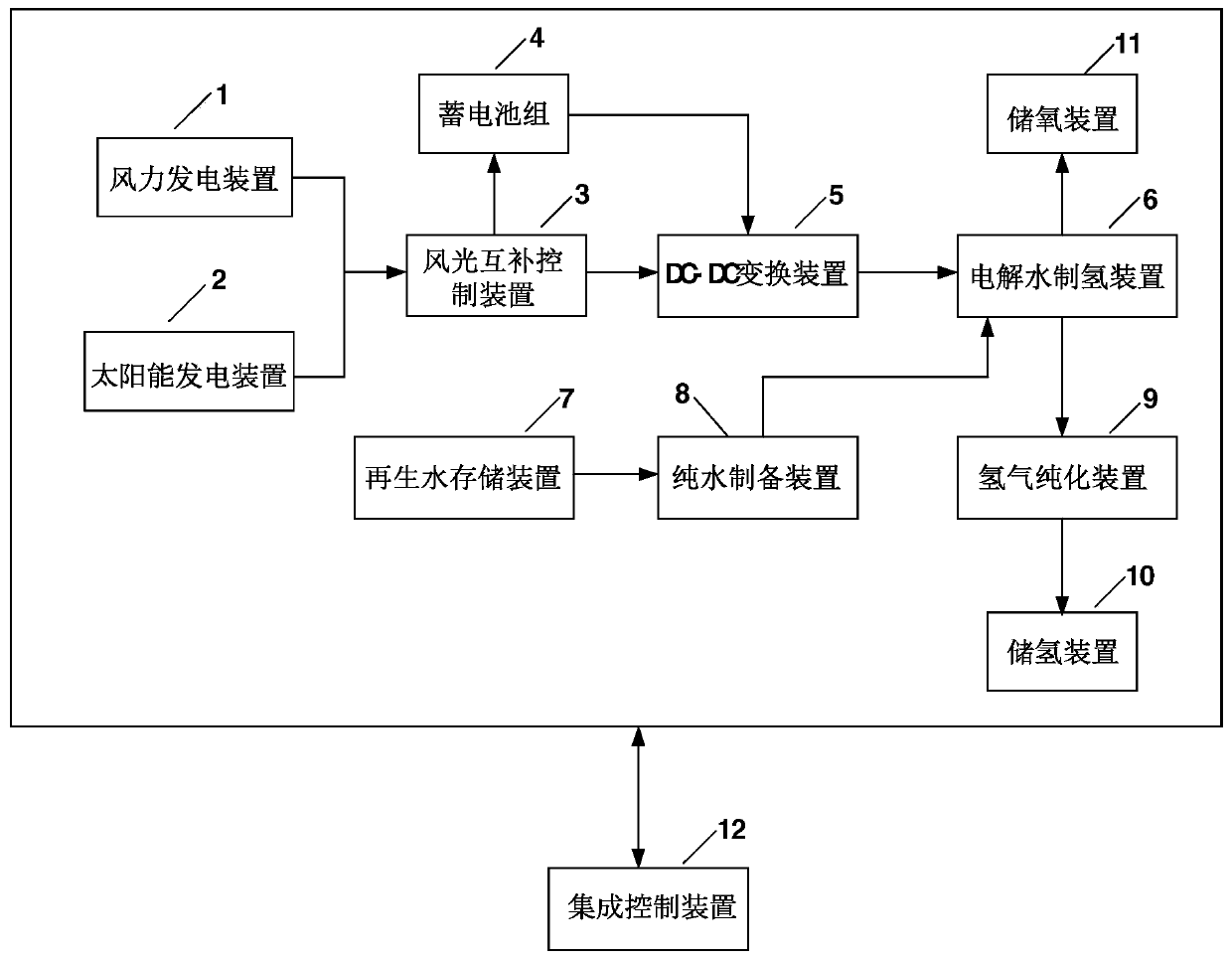

[0028] figure 1 It is a structural block diagram of a distributed power generation hydrogen production system based on a sewage treatment plant according to an embodiment of the present application. A distributed power generation hydrogen production system based on a sewage treatment plant generally includes a wind power generation device 1, a solar power generation device 2, a wind and solar hybrid control device 3, a storage battery pack 4, a DC-DC conversion device 5, an electrolytic water hydrogen production device 6, Regenerated water storage device 7 , pure water preparation device 8 , hydrogen purification device 9 , hydrogen storage device 10 , oxygen storage device 11 and integrated control device 12 . Among them, the wind power generation device 1 and the solar power generation device 2 are regulated and generated by the wind-solar hybrid control device 3 , and the generated electric energy is converted by the DC-DC conversion device 5 and then supplied to the electr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com