A kind of cold-rolled low-alloy high-strength air-cooled strengthened steel for automobiles and its preparation method

A low-alloy high-strength and strengthening steel technology, applied in the field of alloy steel preparation, can solve the problems of high equipment requirements, high processing difficulty and high cost, and achieve the effects of low equipment requirements, low smelting difficulty and low tensile strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The invention provides a cold-rolled low-alloy high-strength air-cooled strengthened steel for automobiles and a preparation method thereof.

[0027] The chemical composition mass percentage of the strengthened steel is: C: 0.05% to 0.15%, Mn: 1.0% to 2.0%, Si: 0.05% to 0.25%, Cr: 0.20% to 1.0%, Mo: 0.05% to 0.3%, Al : 0.01%~0.06%, Nb: 0.01~0.10%, V: 0.01~0.10%, Ti: 0.01~0.10%, B: 0.001~0.006%, P<0.03%, S<0.03%, the balance is Fe and Unavoidable impurities.

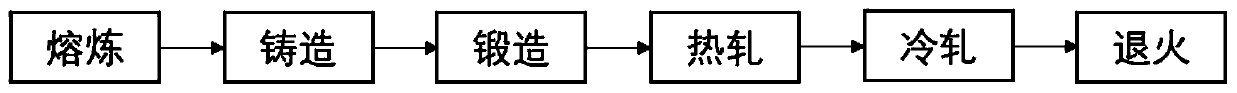

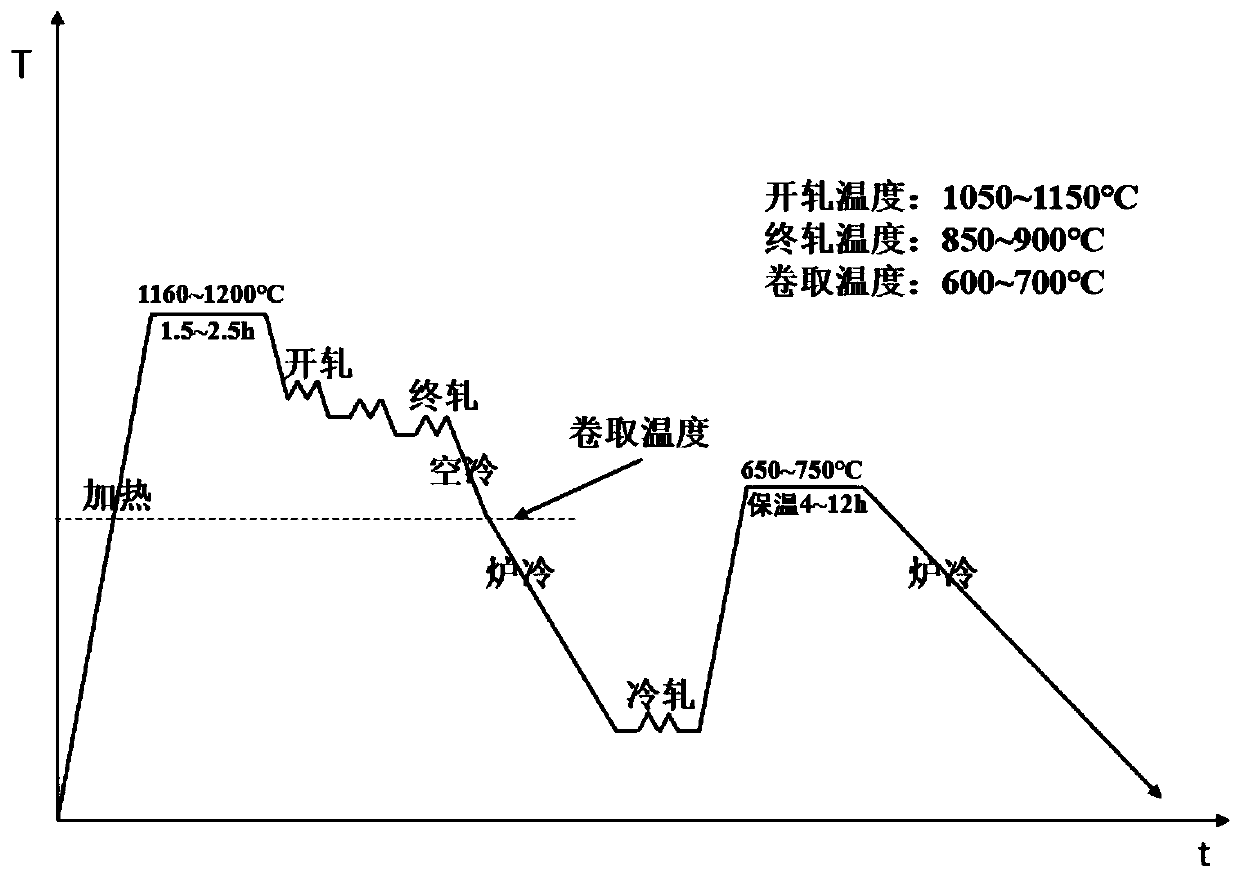

[0028] Such as figure 1 and figure 2 Shown, the preparation method of this strengthened steel comprises steps as follows:

[0029] (1) Preparation of hot-rolled sheet: melting, casting, and forging the raw materials prepared according to the chemical composition ratio to form a slab, heating the slab, and performing multi-pass hot-rolling deformation after homogenization treatment, and air-cooling to coil after hot-rolling Take the temperature and coil it to room temperature to obtain the required hot-rolled s...

Embodiment 1

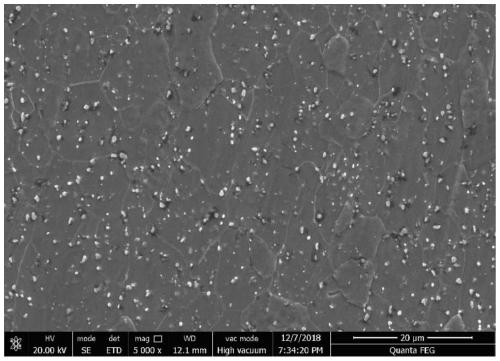

[0034] The chemical composition and mass percentage of cold-rolled low-alloy high-strength air-cooled strengthened steel for automobiles in this embodiment are: C: 0.06%, Mn: 1.05%, Si: 0.17%, Cr: 0.6%, Mo: 0.13%, Al : 0.03%, Nb: 0.02%, V: 0.02%, Ti: 0.02%, B: 0.002%, P<0.03%, S<0.03%, and the balance is Fe and unavoidable impurities.

[0035] The preparation method of cold-rolled low-alloy high-strength air-cooled strengthened steel for automobiles described in this embodiment specifically includes the following steps:

[0036] (1) Forging into slabs after smelting and casting: melt the prepared raw materials in a vacuum induction melting furnace at a melting temperature of 1660°C, and pour them into ingots, forge and deform the ingots, and finally forge them into slabs. The accumulated deformation is 80%. After forging, it is air-cooled to room temperature. The heating temperature of the ingot is 1160°C, the holding time is 2h, the starting forging temperature is 1130°C, and...

Embodiment 2

[0043] The difference from Example 1 is that the annealing temperature of the final cold-rolled sheet is 650°C, and the mechanical properties of the steel sheet after the final annealing treatment are tested according to the national standard, and the yield strength is 335MPa, the tensile strength is 505MPa, and the elongation is 29.8%.

[0044] The annealed sheet obtained after cold rolling can be subjected to cold plastic deformation at room temperature to obtain complex auto parts. After the parts are austenitized at a high temperature of 900°C, they can be air-cooled to room temperature to obtain high-strength and good-toughness auto parts. After testing the mechanical properties of the high-strength auto parts according to the national standard, the yield strength is 686MPa, the tensile strength is 1016MPa, and the elongation is 13.9%, which meets the performance requirements of the new generation of high-strength steel for automobiles.

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com