Preparation method of silicone-modified DNRL grafted copolymer

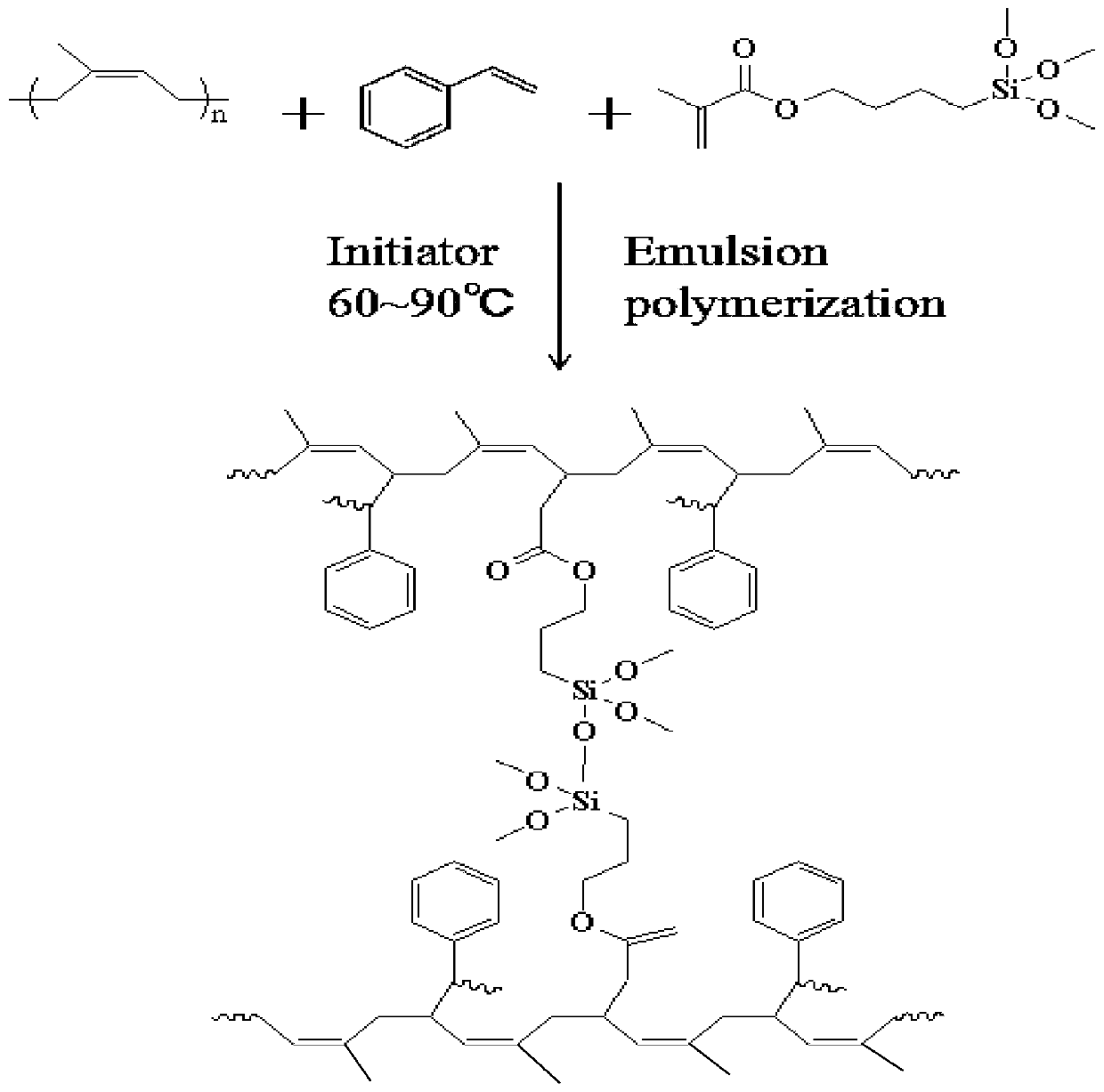

A technology of graft copolymer and organosilicon, which is applied in the field of preparation of organosilicon modified DNRL graft copolymer, can solve the problem of natural rubber tensile properties, heat resistance, low hydrophobicity, antibacterial properties, and low adhesion In order to improve the antibacterial performance and biocompatibility, the process is green and environmentally friendly, and the application prospect is wide.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

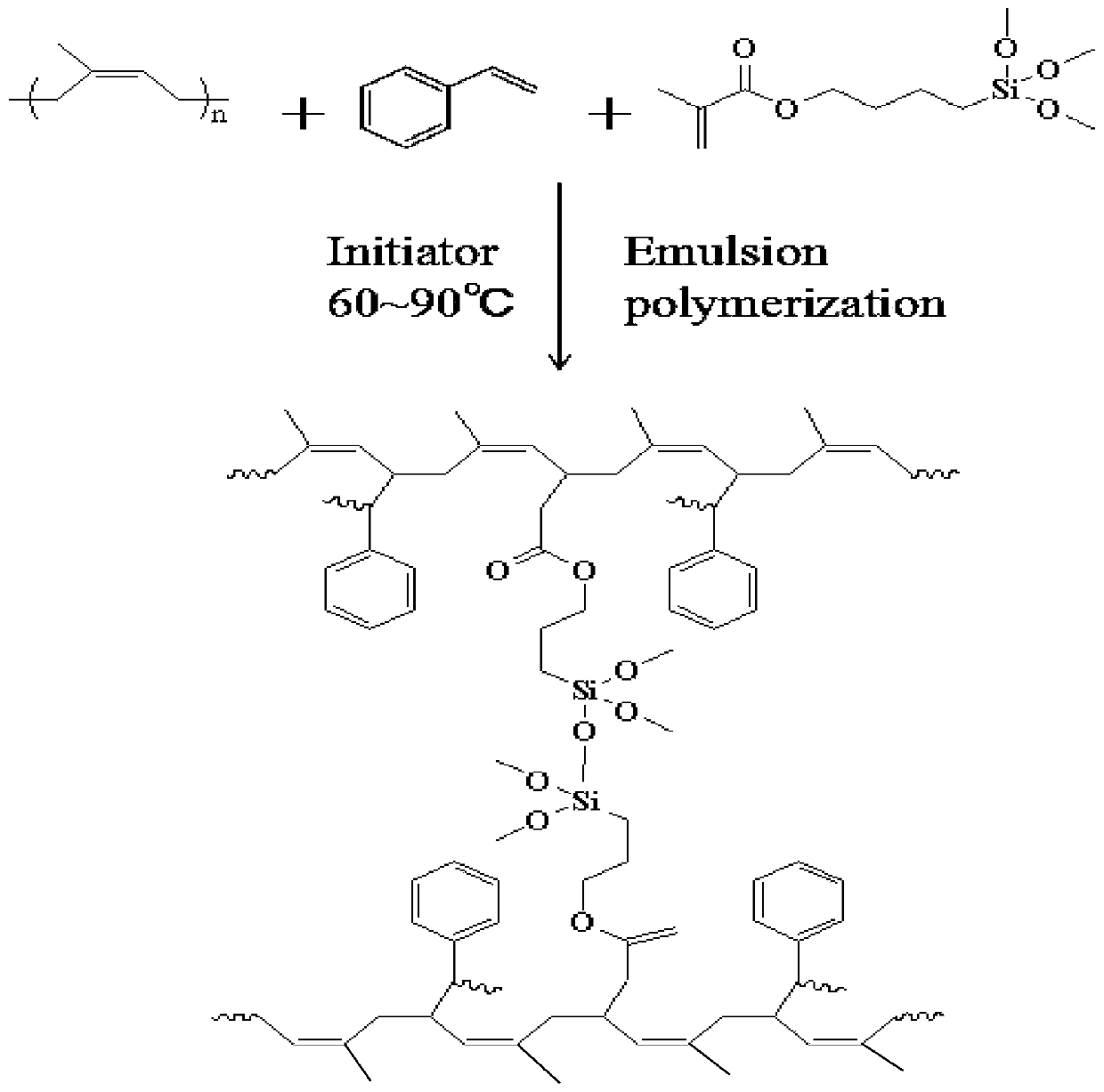

[0040] The present invention also provides a kind of preparation method of organosilicon modified DNRL graft copolymer, comprising the following steps:

[0041] (1) Mix 10-20 parts of hard monomer, 10-30 parts of deionized water, and 0.3-0.8 parts of emulsifier, and stir for 30 minutes under the action of 20000-50000 Hz ultrasonic waves to obtain pre-emulsion A.

[0042] (2) Dissolving 0.05-0.3 parts of initiator in 10-30 parts of deionized water to obtain initiator aqueous solution B.

[0043] (3) Add 40-80 parts of deproteinized natural rubber latex and 1 / 3 pre-emulsion A to a four-necked flask equipped with a mechanical stirring paddle and a reflux condenser, put the flask into an oil bath, and heat to 40-60 ℃, continuously feed nitrogen into the bottle, and stir the mixture at a rate of 200-300r / min. After 30 minutes, raise the temperature of the oil bath to 60-90℃, and drop it into the four-necked flask through a constant pressure dropping funnel. Add 1 / 3 of the initiato...

Embodiment 1

[0048] A method for preparing a silicone-modified DNRL graft copolymer, comprising the following raw materials in parts by weight: 50 parts of deproteinized natural rubber latex (DNRL, w=30%), 10 parts of styrene, vinyltrimethoxysilane 1 part, 12 parts of deionized water, 0.1 part of initiator, 0.3 part of emulsifier;

[0049] The deproteinized natural rubber latex (DNRL, w=30%) is formulated from the following raw materials and steps: 0.2 parts of urea and 1.5 parts of sodium dodecyl sulfate (SDS) are dropped into 200 parts of fresh natural rubber latex (NRL , w=30%), and stirred for 30 minutes, incubated at 30 ° C for 1 hour, and then 10 4 The deproteinization of natural rubber latex was performed at a centrifugal rate of rpm, and the centrifuged cream part was redispersed in deionized water to prepare deproteinized natural rubber latex (DNRL, w=30%).

[0050] A kind of preparation method of organosilicon modified DNRL graft copolymer of the present invention, as following ...

Embodiment 2

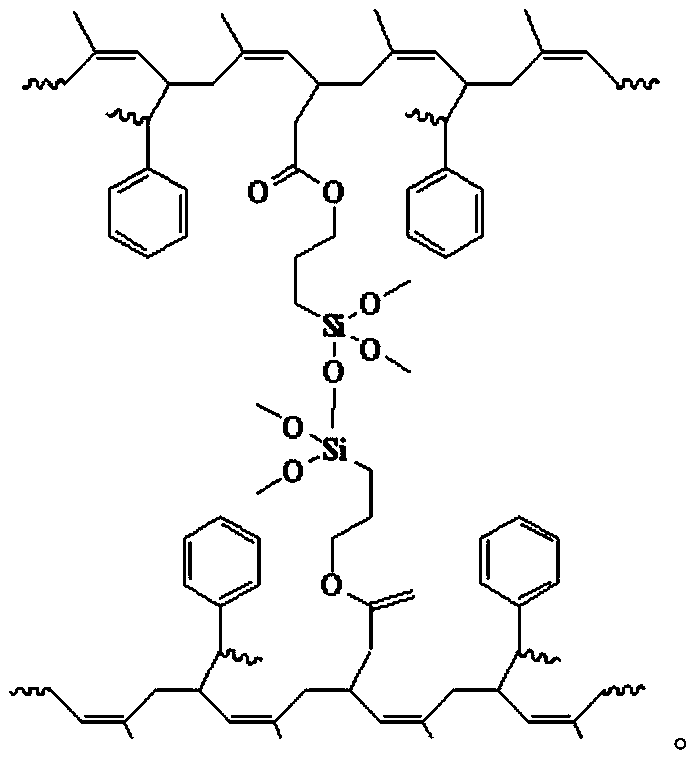

[0058] A method for preparing a silicone-modified DNRL graft copolymer, which consists of the following raw materials in parts by weight: 55 parts of deproteinized natural rubber latex (DNRL, w=30%), 12 parts of styrene, γ-methacryloyl 2 parts of oxypropyltrimethoxysilane, 15 parts of deionized water, 0.11 parts of initiator, 0.3 parts of emulsifier;

[0059] The deproteinized natural rubber latex (DNRL, w=30%) is formulated from the following raw materials and steps: 0.2 parts of urea and 1.5 parts of sodium dodecyl sulfate (SDS) are dropped into 200 parts of fresh natural rubber latex (NRL , w=30%), and stirred for 30 minutes, incubated at 30 ° C for 1 hour, and then 10 4 The deproteinization of natural rubber latex was performed at a centrifugal rate of rpm, and the centrifuged cream part was redispersed in deionized water to prepare deproteinized natural rubber latex (DNRL, w=30%).

[0060] A kind of preparation method of organosilicon modified DNRL graft copolymer of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com