Gypsum powder product process adopting sequential aging and grinding

A gypsum powder and product technology, applied in cement production and other directions, can solve problems such as poor performance of phosphogypsum, agglomeration of insoluble substances, resource shortage, etc., to improve hydration coagulation and mechanical properties, save water resources, and save operation steps. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] 1. The chemical composition of the phosphogypsum used in the present embodiment is shown in the following table 1,

[0041] Table 1 Chemical composition of phosphogypsum

[0042] components Ca0 SO 3

SiO 2

Al 2 o 3

MgO P 2 o 5

F organic matter h 2 o

Mass fraction / % 28.34 40.85 8.12 0.61 0.15 0.81 0.35 0.17 19.15

[0043] According to the above step (1), the phosphogypsum was calcined. Under the condition that the calcination temperature was 2 hours, the influence of different calcination temperatures on the phase of phosphogypsum was investigated. The results are shown in Table 2 below. The results show that: when the calcination temperature is greater than 170°C, the plaster (CaSO 4 1 / 2H 2 The content of O) is more than 70%, and the content of phosphogypsum is less than 9%; as the temperature increases, the content of phosphogypsum gradually decreases to 0, and the content of plaster gradually increa...

Embodiment 2

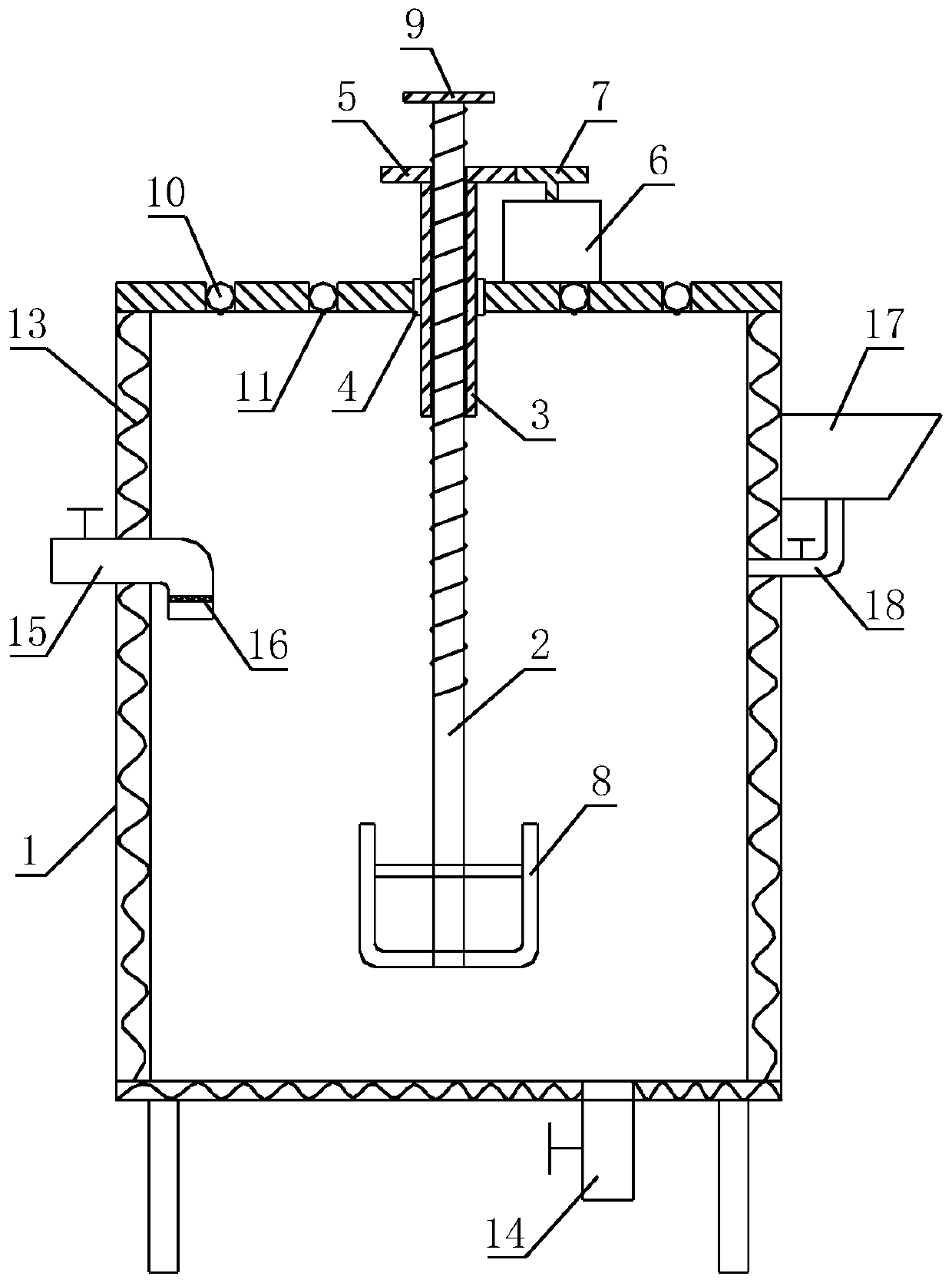

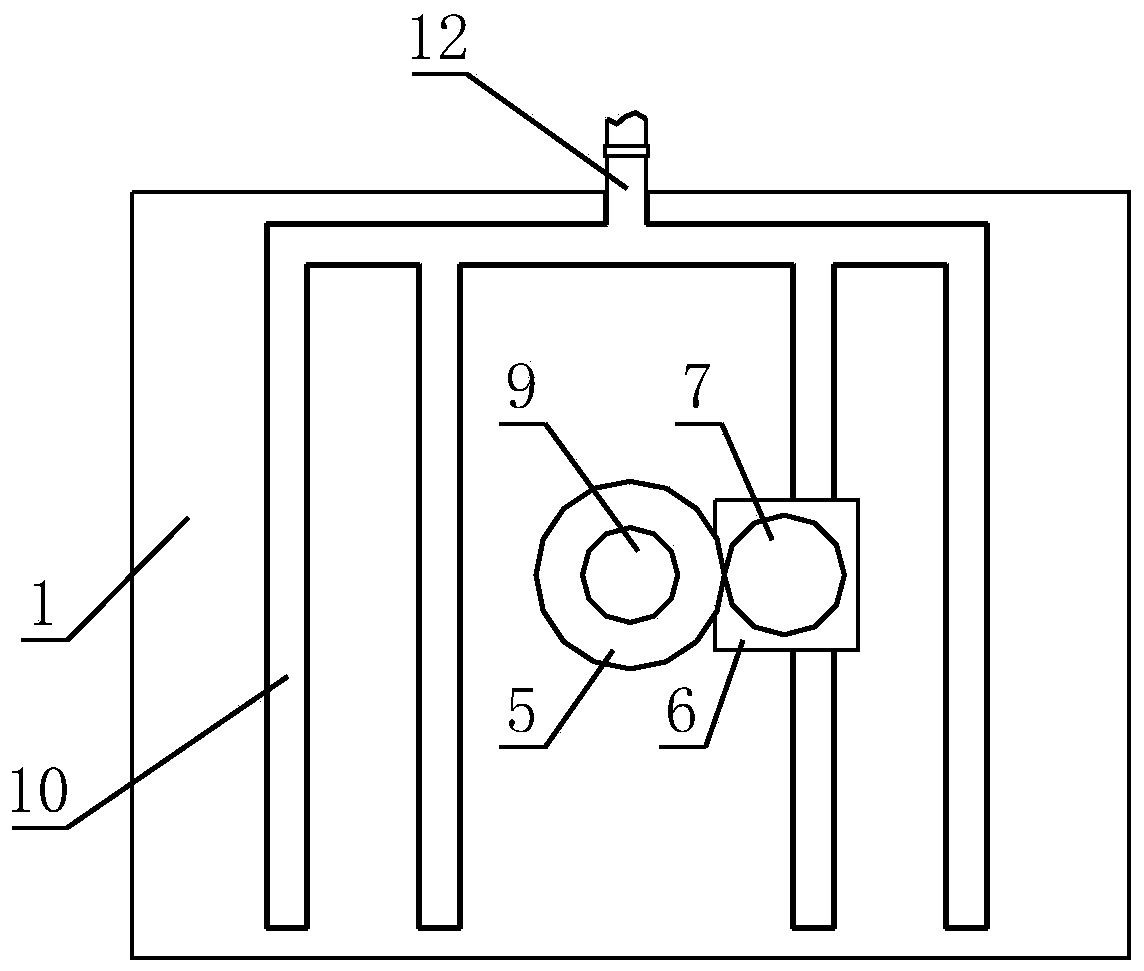

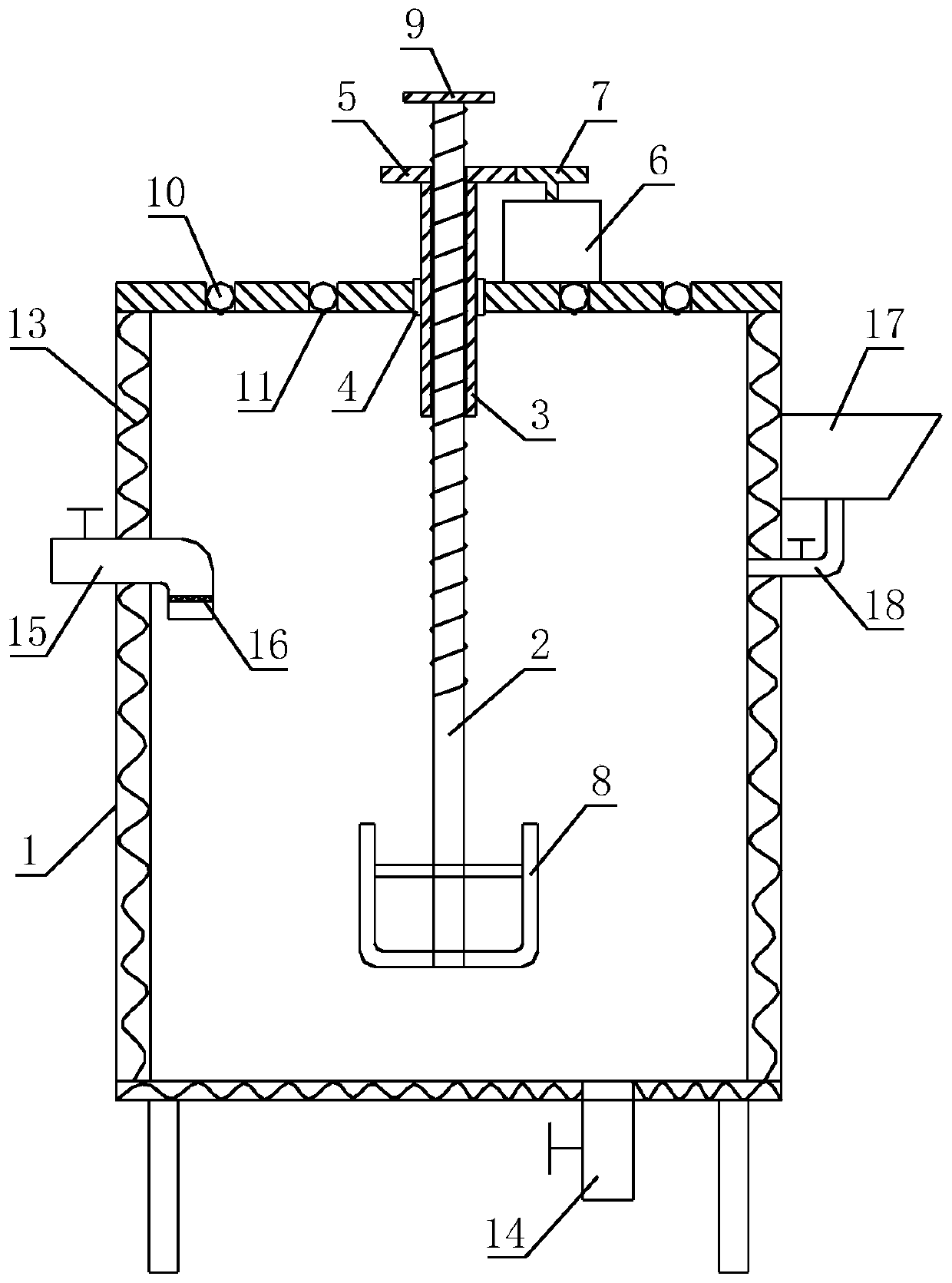

[0068] refer to Figure 1-Figure 2 , the present invention also discloses an aging device, comprising: an aging box 1, a stirring assembly vertically arranged in the aging box 1; The transmission cylinder 3, the transmission cylinder 3 is fixed with the top of the aging tank 1 through the bearing 4. Specifically, the outer wall of the stirring shaft 2 is provided with threads, and the inner wall of the transmission cylinder 3 is also provided with threads. The agitation shaft 2 and the transmission cylinder 3 are driven by the threads, and the rotation of the transmission cylinder 3 makes the agitation shaft 2 move up and down in the aging tank 1 . The transmission cylinder 3 is fixed in the inner ring of the bearing 4, and the outer ring of the bearing 4 is fixed on the top of the aging box 1, so that the transmission cylinder 3 can rotate.

[0069] The top of the transmission cylinder 3 is fixed with a rotating gear 5, the stirring shaft 2 passes through the rotating gear 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com