Laser and arc compound welding method

A hybrid welding and arc technology, used in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of scattering, insufficient thermionic emission, absorption of beams, etc., to increase penetration, improve arc stability, and improve the surface. molding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

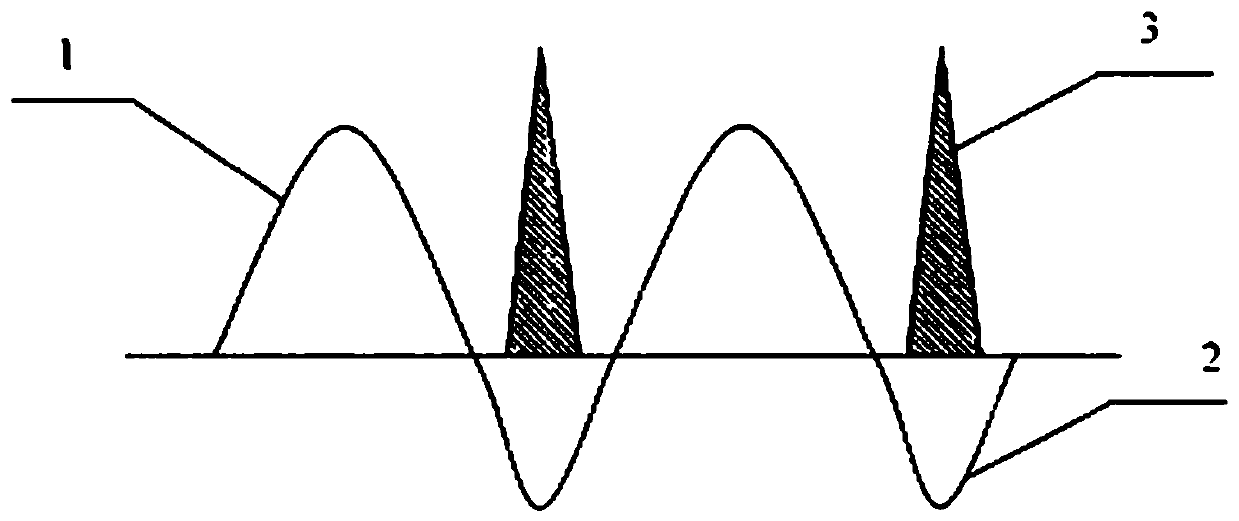

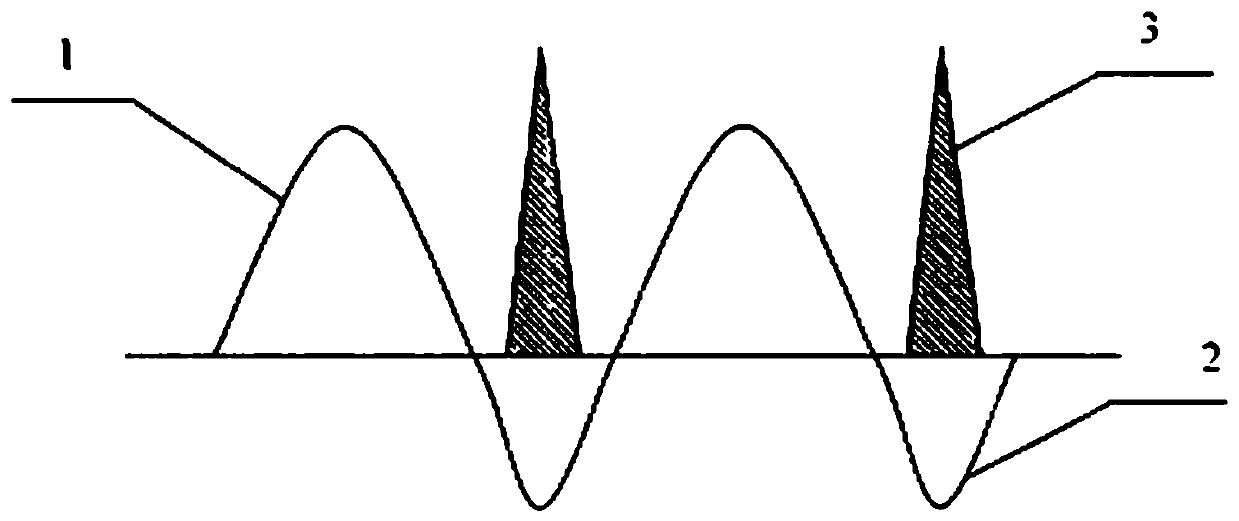

[0020] like figure 1 Shown, a kind of laser and electric arc hybrid welding method of the present invention, described method comprises the steps:

[0021] (1) Activate pulsed laser, synchronous pulse signal control;

[0022] (2) Activate the AC arc and use pulsed laser-AC arc hybrid welding;

[0023] (3) During the welding process, adjust the arc current to 40A-500A, the laser pulse peak power to 1-6KW, the base value power to 200W-1000W, the laser pulse frequency to 10-100Hz, and the distance between the laser impact point and the center of the arc molten pool The distance Dla is 1-6mm, and the distance h from the tip of the electrode to the workpiece is 1-5mm until the welding is completed.

[0024] figure 1 Among them, the positive half-wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com