Non-preheating submerged-arc welding method of EH36 high-strength steel thick plate

A high-strength steel, EH36 technology, applied in arc welding equipment, welding equipment, welding accessories, etc., can solve the problems of large restraint, long production cycle, high production cost, etc., to avoid pre-welding preheating process, reduce production Costs and the effect of shortening the production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] This embodiment discloses a non-preheating submerged arc welding method in which the welding plate is a thick plate of EH36 high-strength steel, wherein the thickness of the thick plate of EH36 high-strength steel is less than or equal to 64mm, specifically including the following steps:

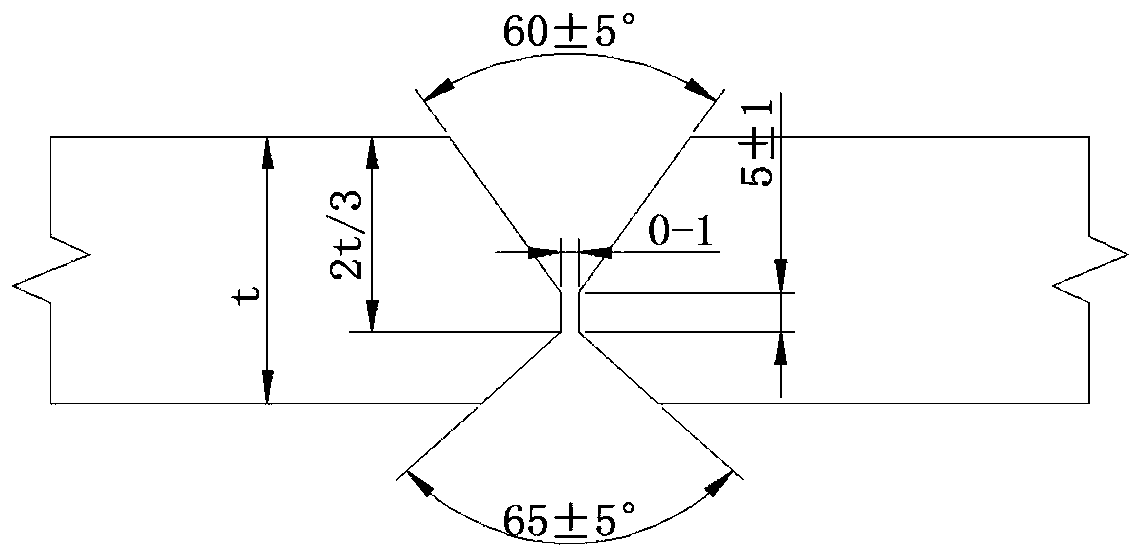

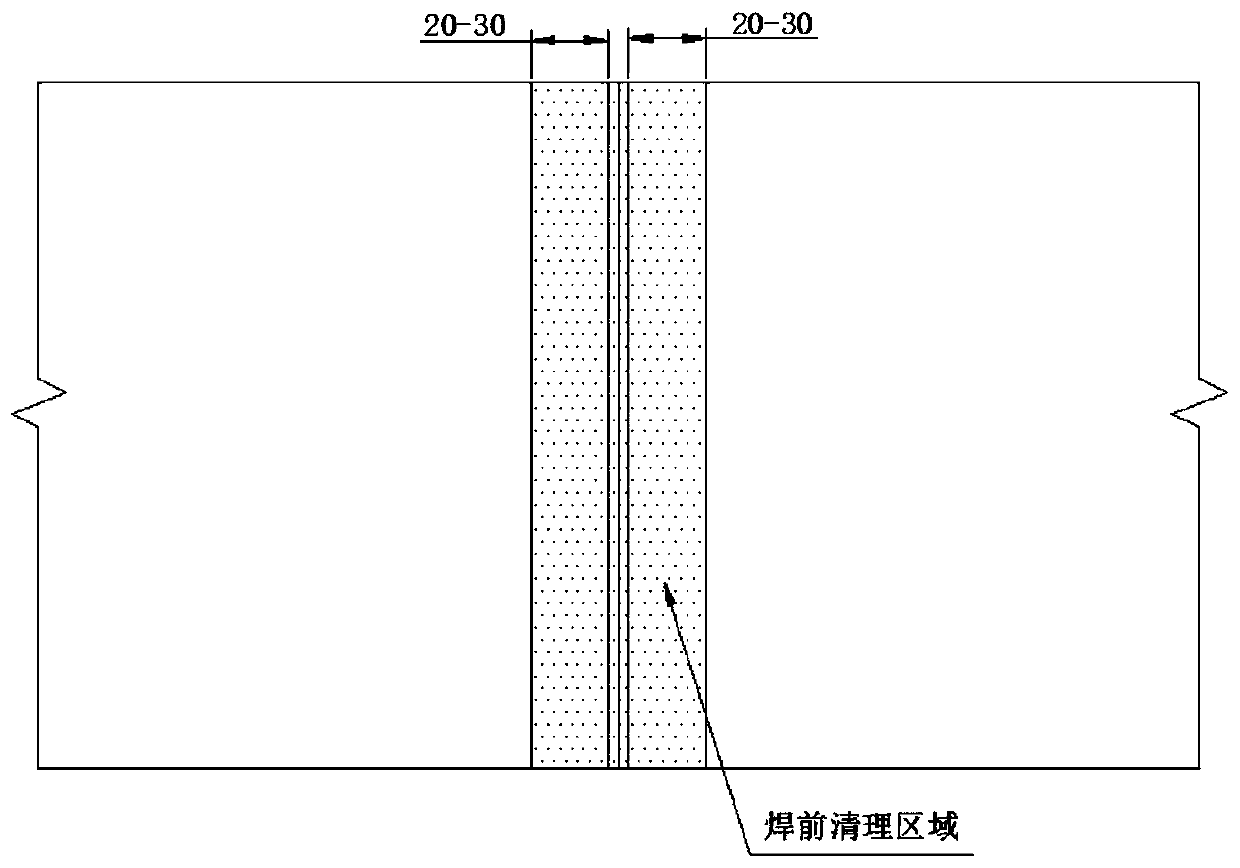

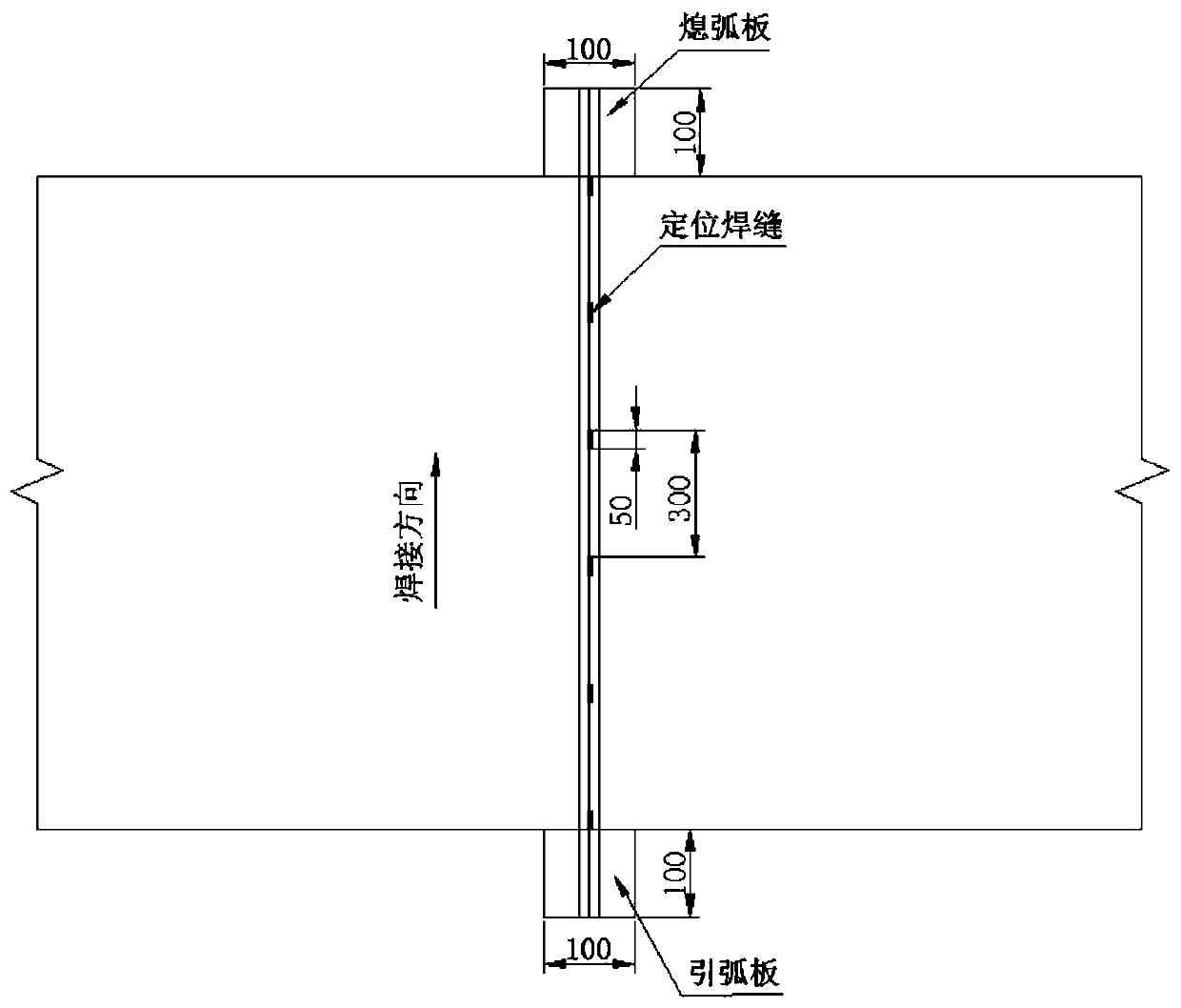

[0035] Step 1, process X-type welding grooves at the welding place of EH36 high-strength steel thick plates, and the corresponding parameters of X-type welding grooves are: the angle of the front groove is 55°~65°, and the depth of the front groove is 2 / 3 thick, the angle of the groove on the back is 60°~70°, the blunt edge is 4~6mm, and the root gap is 0-1mm; after processing, the oxide layer on the X-type welding groove surface and the X-type welding The impurities within 20-30mm around the groove (including the oxide layer, rust, moisture or other impurities at the groove) should be cleaned to prevent the impurities near the X-shaped welding groove from being welded into the weld du...

Embodiment 2

[0058] This embodiment discloses a non-preheating submerged arc welding method in which the welding plate is a thick plate of EH36 high-strength steel, wherein the thickness of the thick plate of EH36 high-strength steel is not less than 64mm, specifically including the following steps:

[0059] Step 1, process X-type welding grooves at the welding place of EH36 high-strength steel thick plates, and the corresponding parameters of X-type welding grooves are: the angle of the front groove is 55°~65°, and the depth of the front groove is 2 / 3 thick, the angle of the groove on the back is 60°~70°, the blunt edge is 4~6mm, and the root gap is 0-1mm; after processing, the oxide layer on the X-type welding groove surface and the X-type welding The impurities within 20-30mm around the groove (including the oxide layer, rust, moisture or other impurities at the groove) should be cleaned to prevent the impurities near the X-shaped welding groove from being welded into the weld during the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com