A cutting suppression treatment method derived from the surface texture of the rake face of a micro turning tool

A technology of surface texture and treatment method, which is applied in the field of micro-turning tool rake face surface texture-derived cutting inhibition treatment, can solve the problems of reduced machining stability, micro-texture wear, instantaneous cutting force fluctuation, etc., to reduce sharpness sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

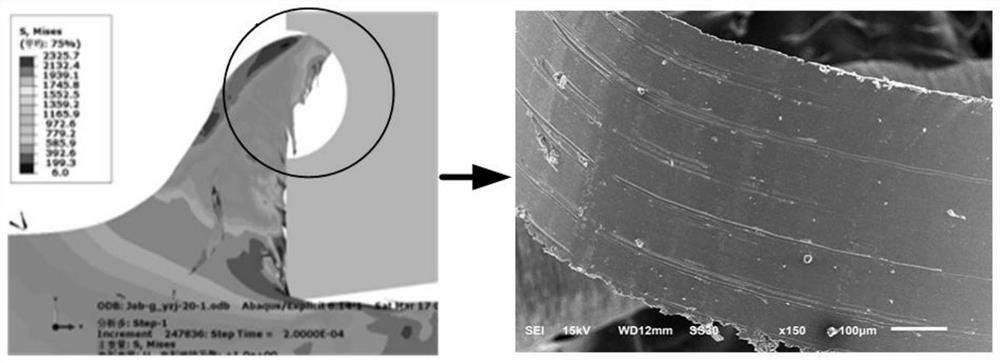

[0029] A micro turning tool rake surface texture derivative cutting, such as figure 1 As shown, the left side of the arrow in the figure is the derived cutting effect of the texture on the chip in the cutting simulation, and the right side of the arrow in the figure is the scratch caused by the texture on the chip surface due to the derived cutting effect in the actual cutting process.

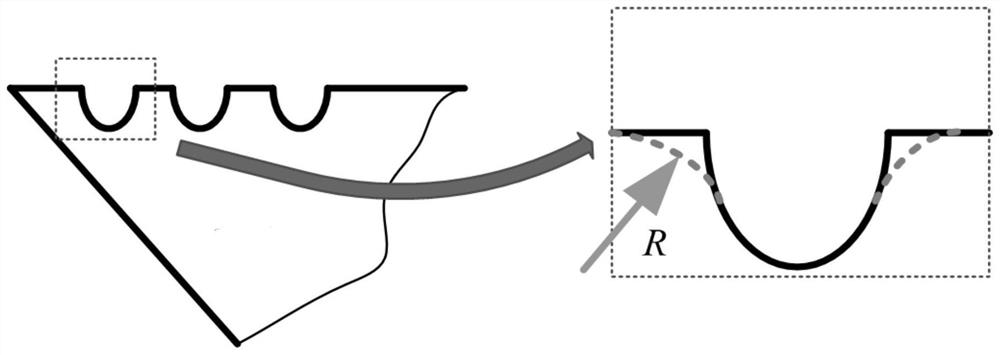

[0030] Therefore the present invention proposes a kind of miniature turning tool rake surface texture derivation cutting suppression processing method,

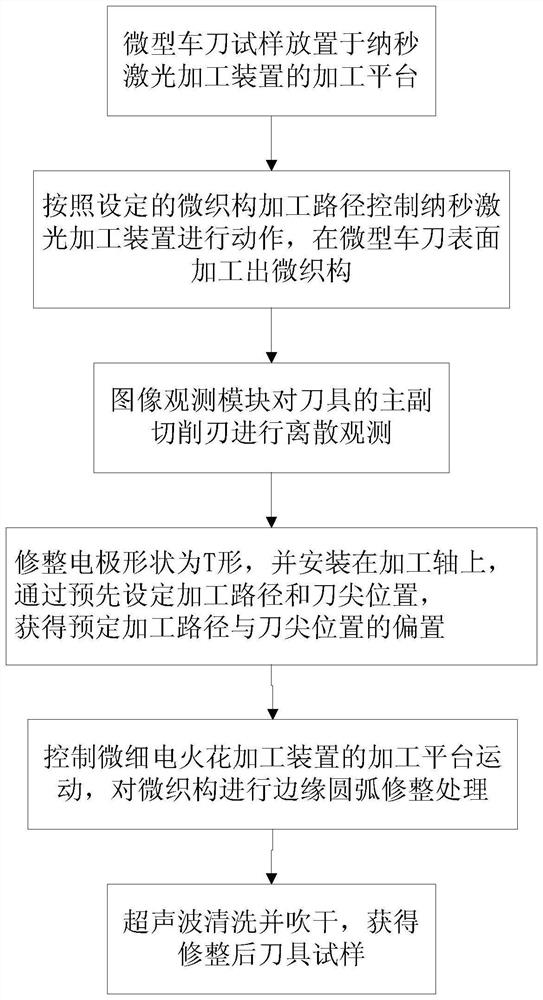

[0031] Such as image 3 shown, including the following steps,

[0032] Step 1. Ultrasonic cleaning and drying of the micro turning tool sample;

[0033] Step 2. Place the micro turning tool sample on the processing platform of the nanosecond laser processing device, where the laser power is 8w, the laser output frequency is 20KHZ, the number of processing repetitions is 20 times, and the laser scanning speed is 300mm / s; according to the set...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com