Production method of natto powder and whitening and freckle-removing nutrient composition containing natto powder

A nutritional composition and a whitening and freckle-removing technology, which are applied in the field of whitening and freckle-removing nutritional compositions, can solve problems such as slow onset of traditional Chinese medicine, and achieve the effects of promoting intestinal peristalsis, improving internal environment, and improving skin aging problems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Present embodiment 1 provides a kind of preparation method of natto powder, it comprises the steps:

[0036] (1) Soya bean, black bean and mung bean are mixed with the mass ratio of 5:1:1, be ground into the powder that crosses 60 mesh sieves, obtain bean powder;

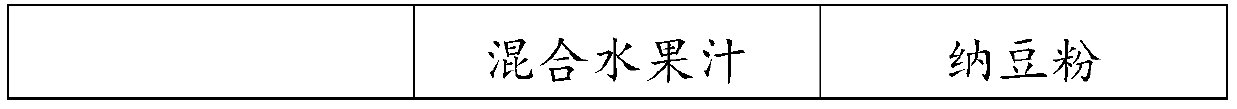

[0037] (2) After the mixed fruit juice is sterilized by Tetra Pak high-temperature instant, soybean powder is added in the mixed fruit juice, the mass ratio of soybean powder and mixed fruit juice is 1:25, and the fermentation substrate is obtained; the mixed fruit juice is composed of the following mass percentages: The composition of components: black wolfberry juice 20%, blueberry juice 20%, mulberry juice 10%, purple grape juice 5%, cranberry juice 10%, black currant juice 30% and raspberry juice 5%;

[0038] (3) Inserting Bacillus natto into the fermentation substrate and culturing at 38° C. for 24 hours to obtain a fermentation broth, the amount of Bacillus natto inserted is 10%;

[0039] (4) The ferme...

Embodiment 2

[0041] Present embodiment 2 provides a kind of preparation method of natto powder, it comprises the steps:

[0042] (1) Mix chickpeas, kidney beans and red beans with a mass ratio of 3:2:1, and pulverize them into powder passing through a 60-mesh sieve to obtain soybean powder;

[0043] (2) After the mixed fruit juice is sterilized by Tetra Pak high-temperature instant, soybean powder is added in the mixed fruit juice, the mass ratio of soybean powder and mixed fruit juice is 1:15, and the fermentation substrate is obtained; the mixed fruit juice is composed of the following mass percentages: The composition of ingredients: black wolfberry juice 20%, blue indigo juice 20%, mulberry juice 10%, purple grape juice 5%, cranberry juice 10%, black currant juice 30% and raspberry juice 5%;

[0044] (3) inserting Bacillus natto into the fermentation substrate, culturing at 38° C. for 24 hours to obtain a fermentation broth, the amount of Bacillus natto inserted is 5%;

[0045] (4) Th...

Embodiment 3

[0047] Present embodiment 3 provides a kind of preparation method of natto powder, it comprises the steps:

[0048] (1) lentils, chickpeas and soybeans are mixed in a mass ratio of 1:3:5, and pulverized into powders passing through a 60-mesh sieve to obtain soybean powder;

[0049] (2) After the mixed fruit juice is sterilized by Tetra Pak high temperature instantaneously, the soybean powder is added to the mixed fruit juice. The mass ratio of the soybean powder to the mixed fruit juice is 1:30 to obtain the fermentation substrate; the mixed fruit juice consists of the following mass percentages: The composition of ingredients: black wolfberry juice 20%, blue indigo juice 20%, mulberry juice 10%, purple grape juice 5%, cranberry juice 10%, black currant juice 30% and raspberry juice 5%;

[0050] (3) Inserting Bacillus natto into the fermentation substrate and culturing at 36°C for 24 hours to obtain a fermentation broth, the amount of Bacillus natto inserted was 8%;

[0051] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com