A kind of film and preparation method thereof and qled device

A thin film and nano metal technology, applied in the field of thin film and its preparation, can solve the problem of low charge transfer efficiency of QLED devices, and achieve the effects of improving the overall charge transfer efficiency, optimizing matching, and increasing electron transfer efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] The following takes the preparation of modified nano-metal oxide film by using nano-zinc oxide powder, 2-amino-5-phenyl-1,3,4-oxadiazole and ethanol as an example to introduce in detail.

[0048] (1) Select nano-zinc oxide powder with a particle size below 0.45 μm, disperse it in ethanol at a concentration of 20 mg / mL, heat it to 60 degrees Celsius in an argon atmosphere and keep it warm for 10 minutes to obtain a nano-zinc oxide solution (colloid form exists). Then inject 2-amino-5-phenyl-1,3,4-oxadiazole into the nano-zinc oxide solution at a molar ratio of 1:10, stir rapidly and keep warm for 30 minutes to obtain a modified nano-zinc oxide solution ;

[0049] (2) After the reaction, spin-coat the modified nano-zinc oxide solution on the substrate in an argon atmosphere to obtain a modified nano-metal oxide film.

Embodiment 2

[0051] The following takes the preparation of modified nanometer metal oxide film by using nanometer titanium dioxide powder, 5-methoxybenzoxazole-2-thiol and methanol as an example to introduce in detail.

[0052] (1) Select nano-titanium dioxide powder with a particle size below 0.45 μm, disperse it in methanol at a concentration of 20 mg / mL, heat it to 50 degrees Celsius in an argon atmosphere and keep it warm for 10 minutes to obtain a nano-titanium oxide solution (colloidal form exist). Then inject 5-methoxybenzoxazole-2-thiol into the nano-zinc oxide solution with a molar ratio of 1:10, stir rapidly and keep warm for 30 minutes to obtain a modified nano-titanium dioxide solution;

[0053] (2) After the reaction, spin-coat the modified nano-titanium dioxide solution on the substrate in an argon atmosphere to obtain a modified nano-metal oxide film.

Embodiment 3

[0055] The following takes the preparation of modified nano-metal oxide thin films by using nano-tin oxide powder, 2-amino-1,3,4-thiadiazole and ethanol as an example to introduce in detail.

[0056] (1) Select nano-tin oxide powder with a particle size below 0.45 μm, disperse it in ethanol at a concentration of 20 mg / mL, heat it to 60 degrees Celsius in an argon atmosphere and keep it warm for 10 minutes to obtain a nano-tin oxide solution (colloid form exists). Then inject 2-amino-1,3,4-thiadiazole into the nano-tin oxide solution at a molar ratio of 1:10, stir rapidly and keep warm for 30 minutes to obtain a modified nano-tin oxide solution;

[0057] (2) After the reaction, spin-coat the modified nano-tin oxide solution on the substrate in an argon atmosphere to obtain a modified nano-metal oxide film.

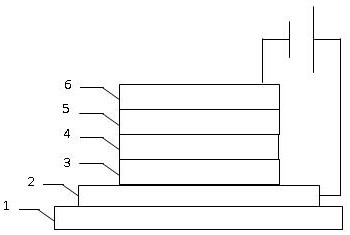

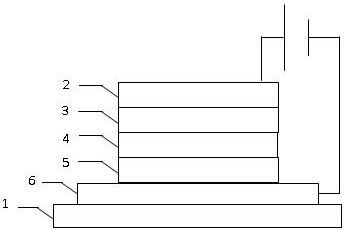

[0058] The present invention also provides a QLED device, comprising an electron transport layer, wherein the electron transport layer is the thin film of the present inve...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com