Method for improving leaching efficiency of gold in pressurized oxidizing slag of gold concentrate

A gold concentrate and oxidized slag technology, applied in the field of hydrometallurgy, can solve problems such as reducing gold leaching rate, and achieve the effects of improving resource utilization rate, high gold recovery rate, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The gold concentrate oxidized slurry obtained by pressurized oxidation of gold concentrate in a pressurized plant contains 22-25g / t of gold, and the sulfur oxidation rate is >98%.

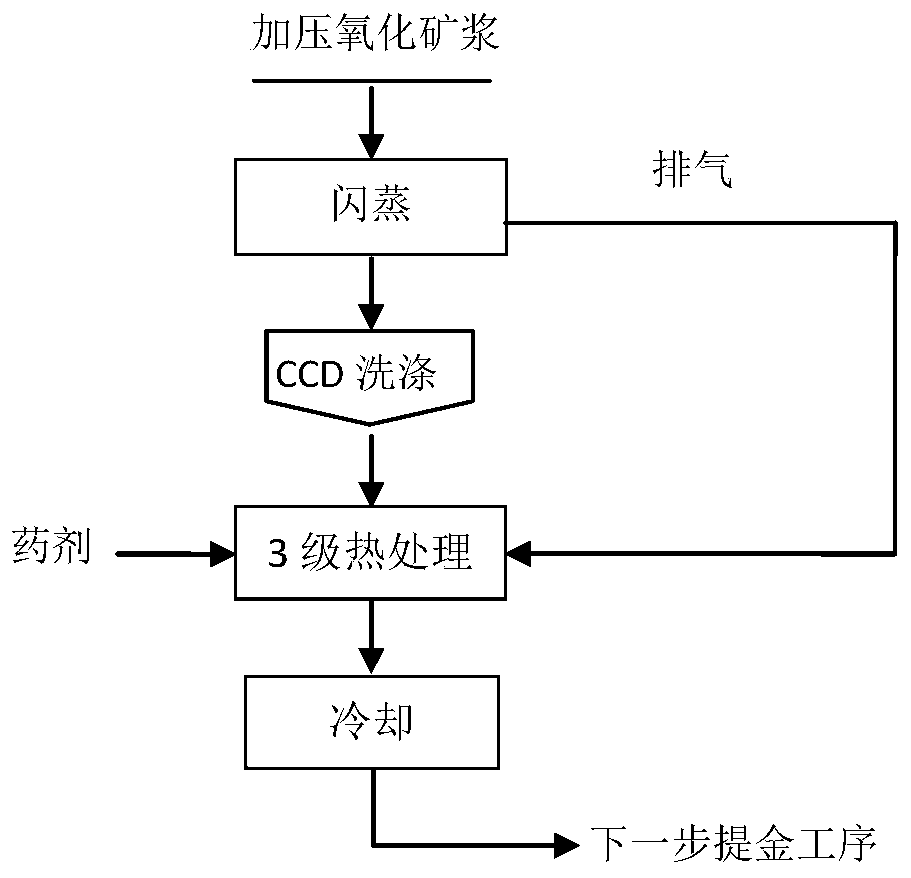

[0027] Such as figure 1 As shown, the mass concentration of gold concentrate oxidized ore pulp after CCD washing is 45%, and the oxidized ore pulp after CCD washing passes through 3 reaction tanks in series successively, and the gold concentrate oxidized ore pulp after washing is subjected to three times in the 3 reaction tanks successively. heat treatment; the three reaction tanks are respectively named No. 1 reaction tank, No. 2 reaction tank and No. 3 reaction tank along the slurry flow direction.

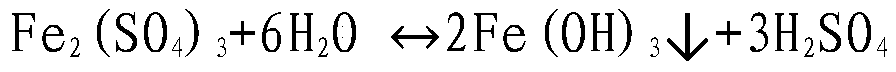

[0028] Use the hot gas discharged from flash evaporation as the heat source, keep the gold concentrate oxidation slurry temperature in No. 1 reaction tank, No. 2 reaction tank and No. potion. The medicament includes 5% limestone and 95% lime by mass percentage, and the total amount of oxidiz...

Embodiment 2

[0032] The gold concentrate oxidized slurry obtained by pressure oxidation of gold concentrate in a pressurized plant contains 28g / t of gold, and the sulfur oxidation rate is >98%.

[0033] The mass concentration of the gold concentrate oxidized pulp after CCD washing is 45%, and the oxidized ore pulp after CCD washing passes through 3 reaction tanks in series in turn, and the washed gold concentrate oxidized pulp is subjected to three-stage heat treatment in the 3 reaction tanks; The three reaction tanks are respectively named as No. 1 reaction tank, No. 2 reaction tank and No. 3 reaction tank along the flow direction of the pulp.

[0034] Use the hot gas discharged from the flash as the heat source, keep the gold concentrate oxidation slurry temperature in the first reaction tank, the second reaction tank and the third reaction tank at 85°C, 80°C, and 75°C respectively potion. The medicament includes 5% of limestone, 35% of calcium carbide slag, and 60% of lime by mass perc...

Embodiment 3

[0038] The gold concentrate oxidized slurry obtained by pressurized oxidation of gold concentrate in a pressurized plant contains 19g / t of gold, and the sulfur oxidation rate is >98%.

[0039] The mass concentration of the gold concentrate oxidized pulp after CCD washing is 45%, and the oxidized ore pulp after CCD washing passes through 3 reaction tanks in series in turn, and the washed gold concentrate oxidized pulp is subjected to three-stage heat treatment in the 3 reaction tanks; The three reaction tanks are respectively named No. 1 reaction tank, No. 2 reaction tank and No. 3 reaction tank along the slurry flow direction.

[0040]Use the hot gas discharged from the flash as the heat source, keep the gold concentrate oxidation slurry temperature in the first reaction tank, the second reaction tank and the third reaction tank at 90°C, 85°C, and 80°C respectively potion. The medicament includes 10% of limestone, 25% of caustic soda, and 65% of lime by mass percentage. Add 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com