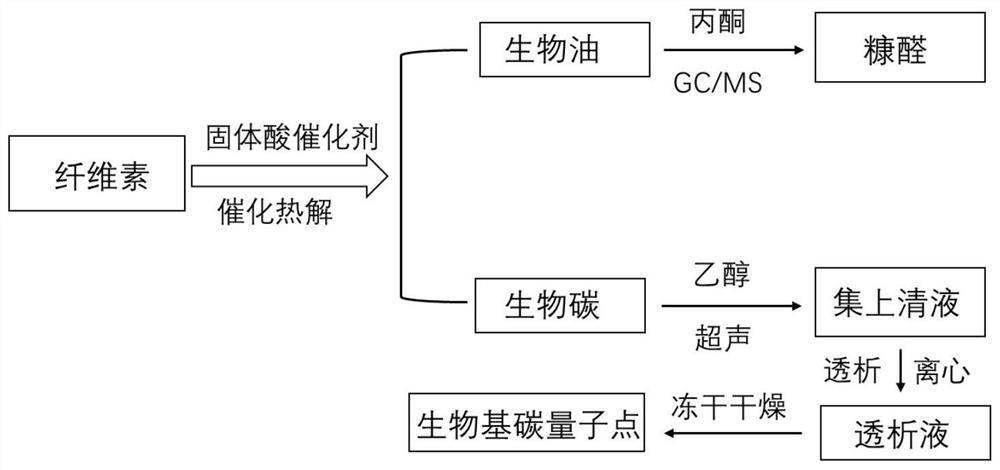

A method and product of biomass co-production of furfural and carbon quantum dots

A technology of carbon quantum dots and biomass, applied in the field of biomass co-production of furfural and carbon quantum dots, can solve the problems of high cost and low application, and achieve the effect of providing yield and high furfural selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] (a) Heat the 40-mesh to 80-mesh biomass raw material at 100°C for 24 hours to dry, and then place the biomass raw material and the Na / Fe composite solid acid catalyst in the first part of the reactor at a mass ratio of 1:10. In the reaction zone and the second reaction zone, feed nitrogen into the reactor to pressurize to 1.5MPa, put the reactor into the reactor after the two-stage fixed bed reaches 750°C, and heat for 15 minutes to pyrolyze the biomass raw material to produce solid products and volatile matter, wherein the volatile matter undergoes secondary cracking under the catalysis of the solid acid catalyst, and then enters the condensation device to form a liquid product;

[0050] (b) After the reaction is completed, cool to room temperature and release the pressure to atmospheric pressure, use methanol to extract the liquid product to obtain furfural, and dissolve the solid product in ethanol solvent, the mass ratio of solid product to ethanol solvent is 1:30, u...

Embodiment 2

[0055] In this embodiment, the temperature of the fixed bed is 550° C., and other conditions are the same as in Embodiment 1.

Embodiment 3

[0057] In this embodiment, the temperature of the fixed bed is 650° C., and other conditions are the same as in Embodiment 1.

[0058] Figure 5 It is the GC peak area of the furfural that embodiment 1~3 makes and the GC peak area percentage figure of each product, as can be seen from the figure, the selectivity of furfural is very high in the furan compound product, and all proportion is greater than in the furan compound 50%, and with the increase of heating temperature, the yield of furfural (peak area percentage) increases first and then decreases, and reaches the maximum at 650°C;

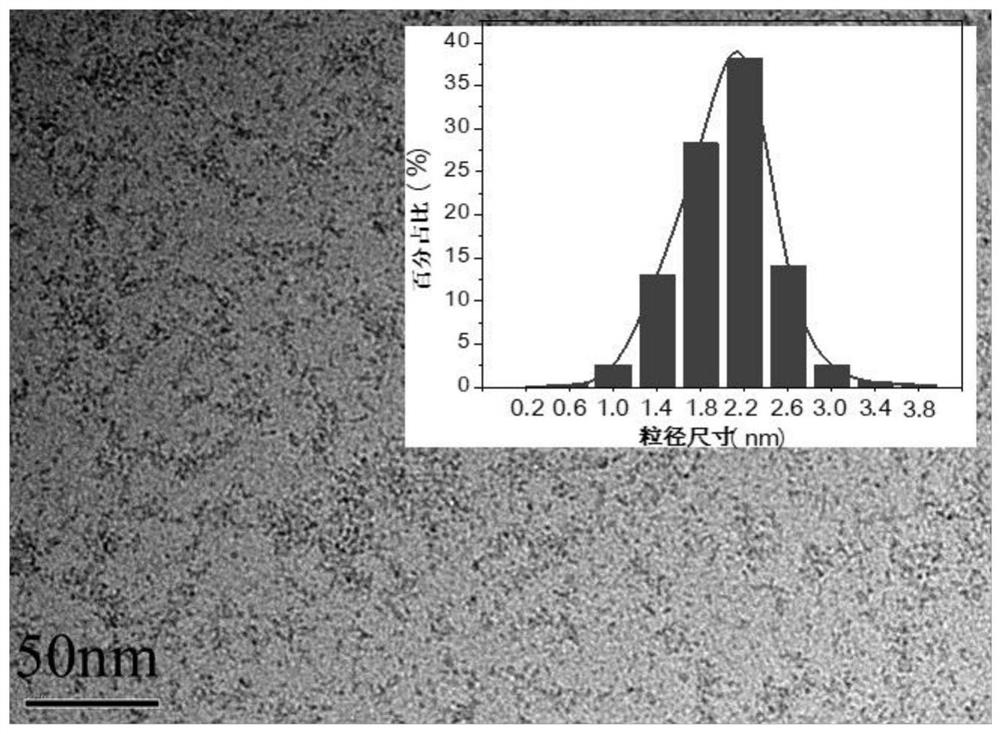

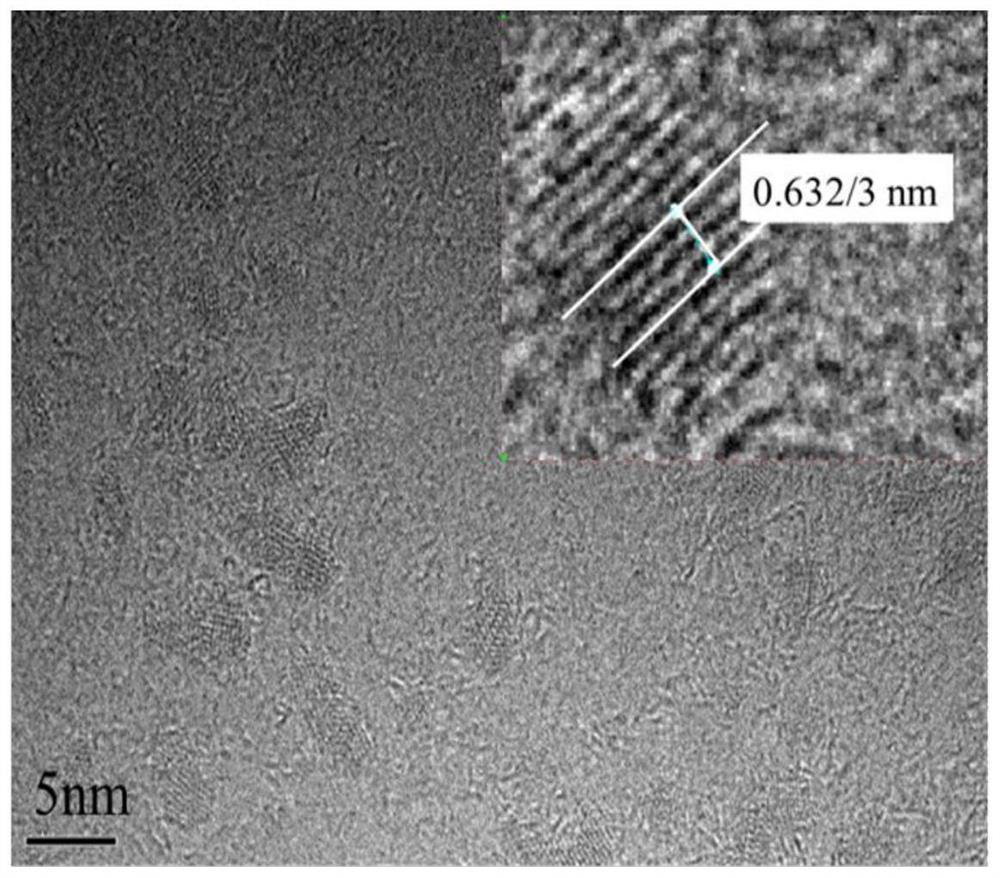

[0059] Image 6 It is the FTEM result figure of the carbon quantum dots that comparative example 1 and embodiment 1~3 make, wherein a, b, c, d are the carbon that comparative example 1, embodiment 2, embodiment 3, embodiment 1 make respectively Quantum dots, the results show that the low-temperature pyrolysis in Comparative Example 1 is highly aggregated amorphous biomass carbon, and as th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com