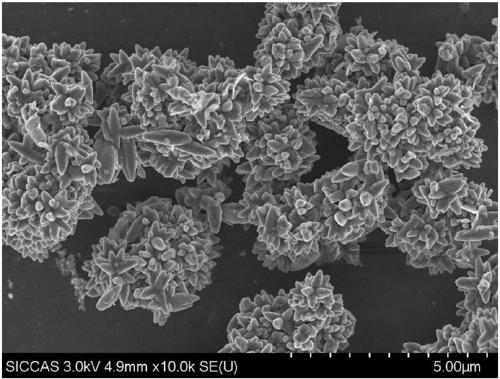

Method for preparing flower-sphere-shaped light calcium carbonate by using ultra-fine ground heavy calcium carbonate as seed crystal

A light calcium carbonate, ultra-fine grinding technology, applied in calcium carbonate/strontium/barium, chemical instruments and methods, calcium/strontium/barium compounds, etc., can solve the problem of poor light scattering ability of curd-shaped light calcium carbonate, etc. problem, to achieve the effect of mild reaction conditions and simple process equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Take 1L of ultra-fine ground heavy calcium GCC95 protoplasm (solid content 75%, viscosity 220cP, D90=1.32μm) produced by Dongsheng New Materials (Shandong) Co., Ltd., add water to dilute to a solid content of 25%, and dilute it with 0.8-1.25mm silicon Zirconium acid beads are used as grinding media, and are ground to a particle size of D90 of 0.52 μm and D50 of 0.24 μm with a small grinder, and the ground heavy calcium slurry is used as a seed crystal. Then take 20L of fine pulp and pass it through 80-mesh nylon mesh, adjust it to a solid content of 16%, and add it to a self-made reaction kettle. Add GCC as the seed crystal according to the ratio of 20‰ of seed crystal GCC (dried) / PCC (dried), and stir for 10 minutes until uniform. The initial temperature is 37°C, the gas flow rate is 60L / h, the kiln gas concentration is 30%, the stirring speed is 700rpm, the carbonization is carried out by ventilation, and the carbonization is completed when the pH is less than or equa...

Embodiment 2

[0025] Take 1L of ultra-fine ground heavy calcium GCC95 protoplasm (solid content 75%, viscosity 220cP, D90=1.32μm) produced by Dongsheng New Materials (Shandong) Co., Ltd., add water to dilute to a solid content of 25%, and dilute it with 0.8-1.25mm silicon Zirconium acid beads are used as grinding media, and are ground to a particle size of D90 of 0.52 μm and D50 of 0.24 μm with a small grinder, and the ground heavy calcium slurry is used as a seed crystal. Then take 20L of fine pulp and pass it through 80-mesh nylon mesh, adjust it to a solid content of 16%, and add it to a self-made reaction kettle. Add GCC as a seed crystal at a ratio of 15‰ of seed crystal GCC (dried) / PCC (dried), and stir for 10 minutes until uniform. The initial temperature is 38°C, the gas flow rate is 60L / h, the kiln gas concentration is 30%, the stirring speed is 700rpm, the carbonization is carried out by ventilation, and the carbonization is completed when the pH is less than or equal to 7.5. Lig...

Embodiment 3

[0027] Take 1L of ultra-fine ground heavy calcium GCC95 protoplasm (solid content 75%, viscosity 220cP, D90=1.32μm) produced by Dongsheng New Materials (Shandong) Co., Ltd., add water to dilute to a solid content of 25%, and dilute it with 0.8-1.25mm silicon Zirconium acid beads are used as grinding media, and are ground to a particle size of D90 of 0.52 μm and D50 of 0.24 μm with a small grinder, and the ground heavy calcium slurry is used as a seed crystal. Then take 20L of fine pulp and pass it through 80-mesh nylon mesh, adjust it to a solid content of 16%, and add it to a self-made reaction kettle. Add GCC as a seed crystal at a ratio of 10‰ of seed crystal GCC (dried) / PCC (dried), and stir for 10 minutes until uniform. The initial temperature is 40°C, the gas flow rate is 60L / h, the kiln gas concentration is 30%, the stirring speed is 700rpm, the carbonization is carried out by ventilation, and the carbonization is completed when the pH is less than or equal to 7.5. Lig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com