High-loading capacity polymethoxyflavones instant microcapsule powder and preparation method thereof

A technology of polymethoxylated flavonoids and microcapsule powder, which is applied in the direction of microcapsules, capsule delivery, pharmaceutical formulations, etc., can solve the problems of underutilization of citrus peel by-products and waste of resources, and improve structure and environmental stability. Cost-saving and cholesterol-lowering effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

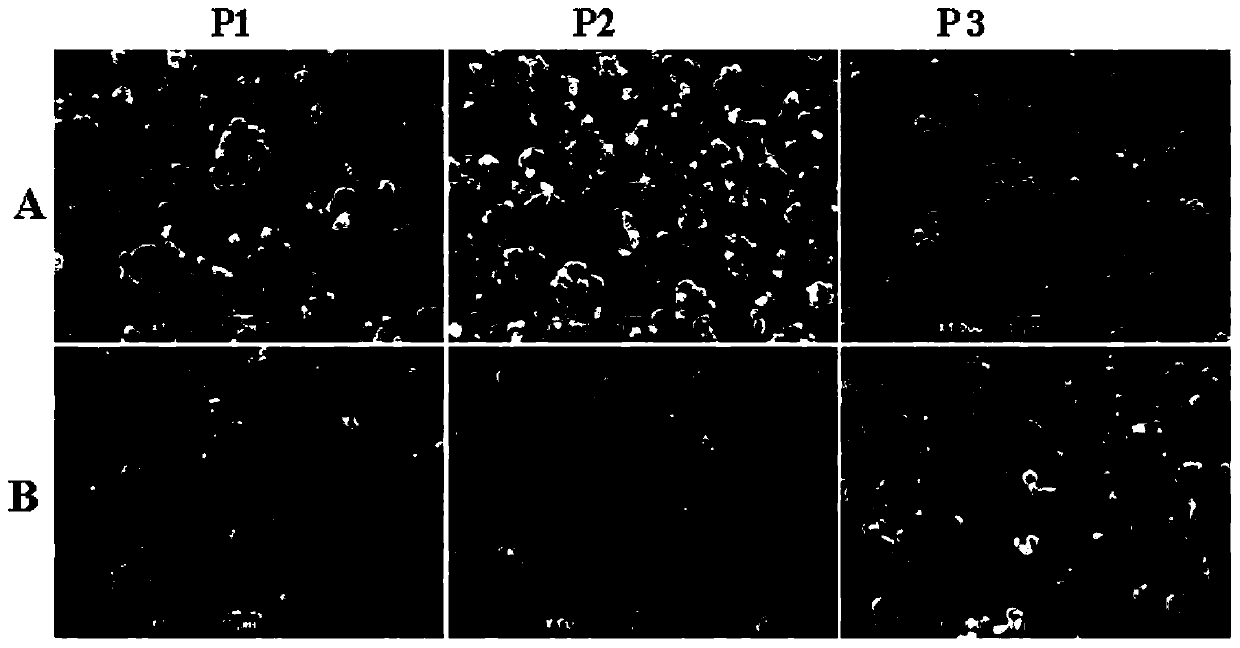

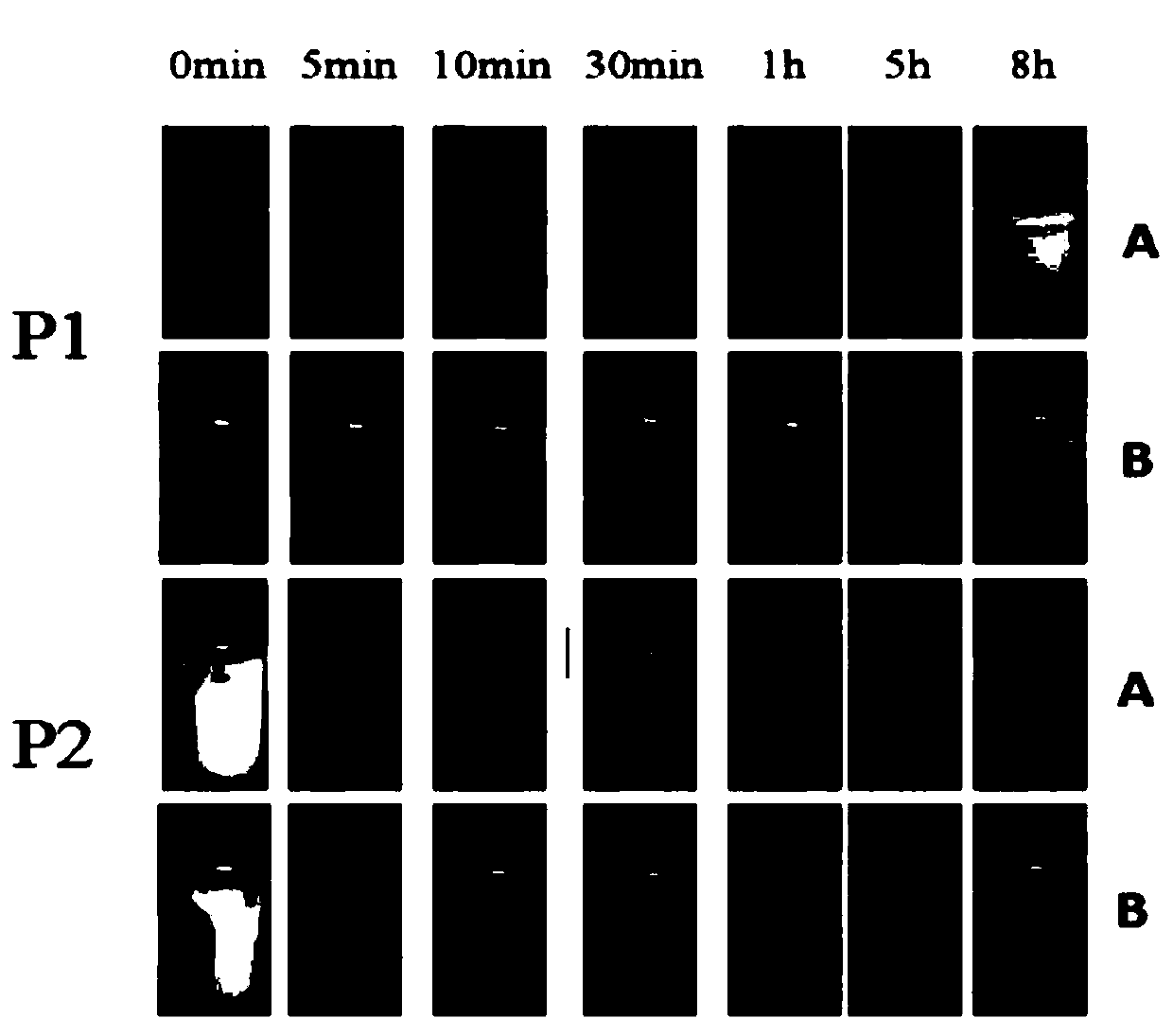

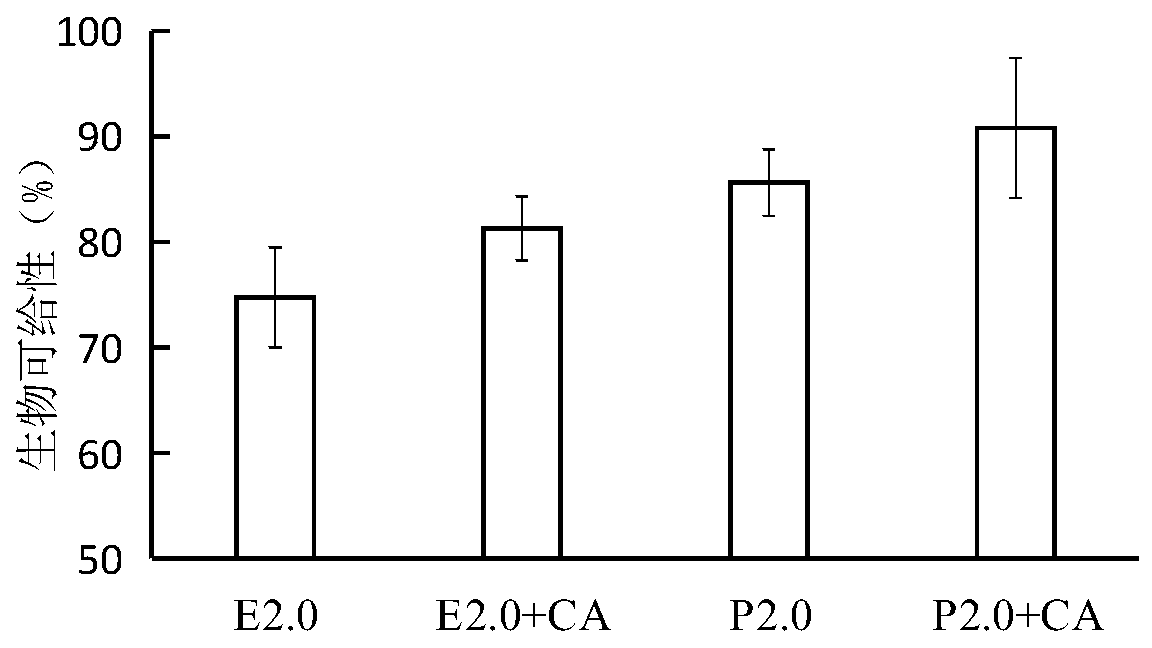

Embodiment 1

[0036] A kind of high-load polymethoxyflavone instant microcapsule powder of the present embodiment is made up of each component of following content:

[0037]

[0038] The above-mentioned high-load polymethoxyflavone instant microcapsule powder of the present embodiment is prepared by the following method, including the following steps:

[0039] (1) Prepare the oil phase: mix 9g of soybean oil with 1g of cinnamon essential oil evenly, add 0.4g of nobiletin, heat to 90°C, and keep stirring for 1 hour. After the nobiletin in the oil phase is completely melted, keep it warm for later use;

[0040] (2) Prepare the water phase: Add 4.5g whey protein concentrate to 85.1g distilled water, keep stirring for 2 hours until the protein is fully dispersed, then put it at 4°C overnight and set it aside for later use.

[0041] (3) Mix the oil phase and the water phase, in an ice bath, under the condition of 12000rad / min, high-speed shearing for 3min until the water phase and the oil pha...

Embodiment 2

[0044] A kind of high-load polymethoxyflavone instant microcapsule powder of the present embodiment is made up of each component of following content:

[0045]

[0046] The above-mentioned high-load polymethoxyflavone instant microcapsule powder of the present embodiment is prepared by the following method, including the following steps:

[0047] (1) Prepare the oil phase: mix 19g of soybean oil with 1g of cinnamon essential oil evenly, add 0.4g of tangeretin, heat to 90°C, and keep stirring for 1 hour. After the tangeretin in the oil phase is completely melted, keep it warm for later use;

[0048] (2) Prepare the water phase: add 7.2g soybean protein isolate to 72.4g distilled water, continue to stir for 2 hours until the protein is fully dispersed, then put it at 4°C overnight for later use.

[0049] (3) Mix the oil phase and the water phase, in an ice bath, under the condition of 12000rad / min, high-speed shearing for 3min until the water phase and the oil phase are fully...

Embodiment 3

[0052] A kind of high-load polymethoxyflavone instant microcapsule powder of the present embodiment is made up of each component of following content:

[0053]

[0054] The above-mentioned high-load polymethoxyflavone instant microcapsule powder of the present embodiment is prepared by the following method, including the following steps:

[0055] (1) Prepare the oil phase: mix 9g of soybean oil with 1g of lemon essential oil, add 0.4g of nobiletin, heat to 90°C, and keep stirring for 1 hour. After the nobiletin in the oil phase is completely melted, keep it warm for later use;

[0056] (2) Prepare the water phase: Add 0.9g whey protein concentrate to 88.7g distilled water, keep stirring for 2 hours until the protein is fully dispersed, then put it at 4°C overnight and set it aside for later use.

[0057] (3) Mix the oil phase and the water phase, in an ice bath, under the condition of 12000rad / min, high-speed shearing for 3min until the water phase and the oil phase are ful...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com