Large-span thin-film plastic greenhouse for year-round production of Yangtze river basin region

A technology for greenhouses in the Yangtze River Basin, applied in the field of greenhouses, can solve the problems that solar greenhouses are not suitable for development, and achieve the effects of being suitable for mechanized operations, improving corrosion resistance, and improving poor heat preservation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

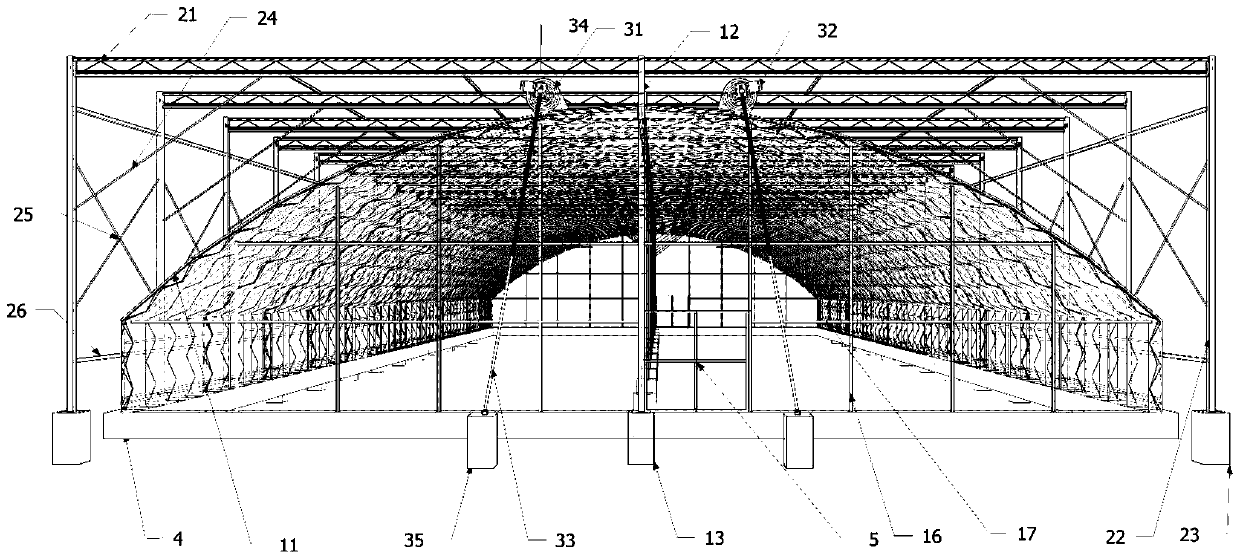

[0054] Such as Figure 1-Figure 11 Shown is a large-span film plastic greenhouse used for annual production in the Yangtze River Basin. The greenhouse extends north-south, with a length of 48.0m, a span of 20.0m, a shoulder height of 1.8m, and a ridge height of 6.0m; the shading system is 7.0m high.

[0055] The film plastic greenhouse includes a greenhouse frame, a sunshade system and a thermal insulation system.

[0056] The greenhouse skeleton includes an inner column 12 fixed by an inner column foundation 13 and a greenhouse arch 11 supported by the inner column 12 .

[0057] The inner columns 12 are arranged in a row in the north-south direction, and the interval between two adjacent inner columns is 4.0m. The inner column scissors bracing 121 in the middle and the arch longitudinal beam 14 in the upper part (ab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com