Method for preparing magnetic meso-porous silica composite microspheres via weak hydrolysis system

A mesoporous silica and hydrolysis system technology, which is applied in the fields of magnetic materials, magnetic objects, inductors/transformers/magnets, etc., can solve the problems of complex synthesis and low coating efficiency, and achieve simple preparation steps and comprehensive synthesis methods. The effect of stability and easy access to raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

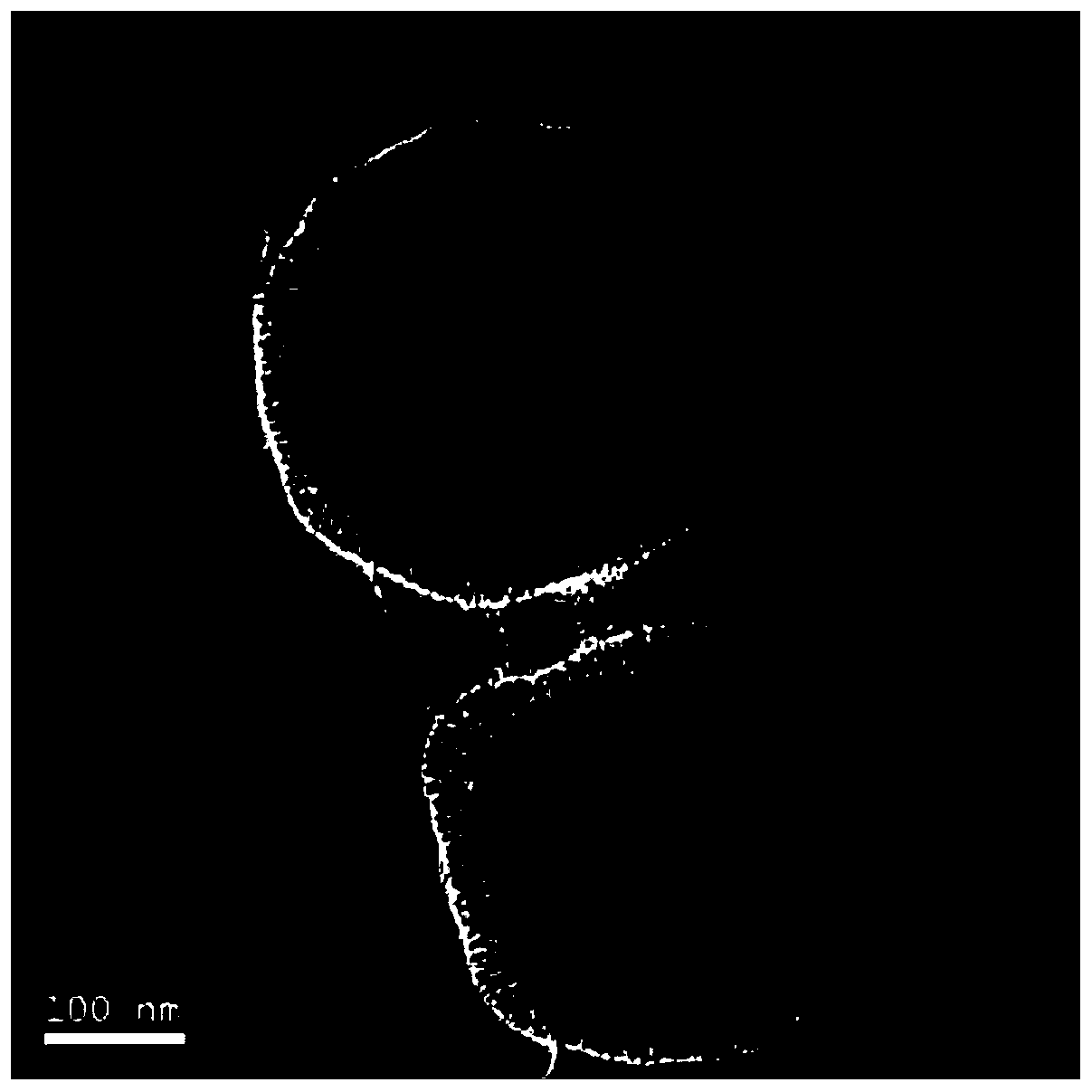

[0029] (1) Evenly disperse 50mg of magnetic iron ferric oxide particles with a size of about 300nm in 100ml of water, 1.5g of 1,3,5-trimethylbenzene, 0.05g of L-arginine and 0.5g of hexadecyltrimethylbenzene After stirring for 30 minutes, 0.5g tetraethyl orthosilicate (TEOS) was added dropwise to a solution of ammonium chloride (CTAC), and stirred at 50°C for 24 hours to obtain magnetic nanoparticles / containing pore-enlarging agent and The silica core-shell composite microspheres of the surfactant, the thickness of the pore expander / surfactant / silica composite coating layer is 60nm; the product is collected with a magnet, and washed 3 times with absolute ethanol and water;

[0030] (2) The above-mentioned washed magnetic nanoparticles / silica core-shell composite microspheres containing pore expanders and surfactants were calcined at 400°C for 3 hours in an air atmosphere to obtain ferric oxide@mesoporous silica core Shell composite microspheres.

[0031] The magnetic nanopart...

Embodiment 2

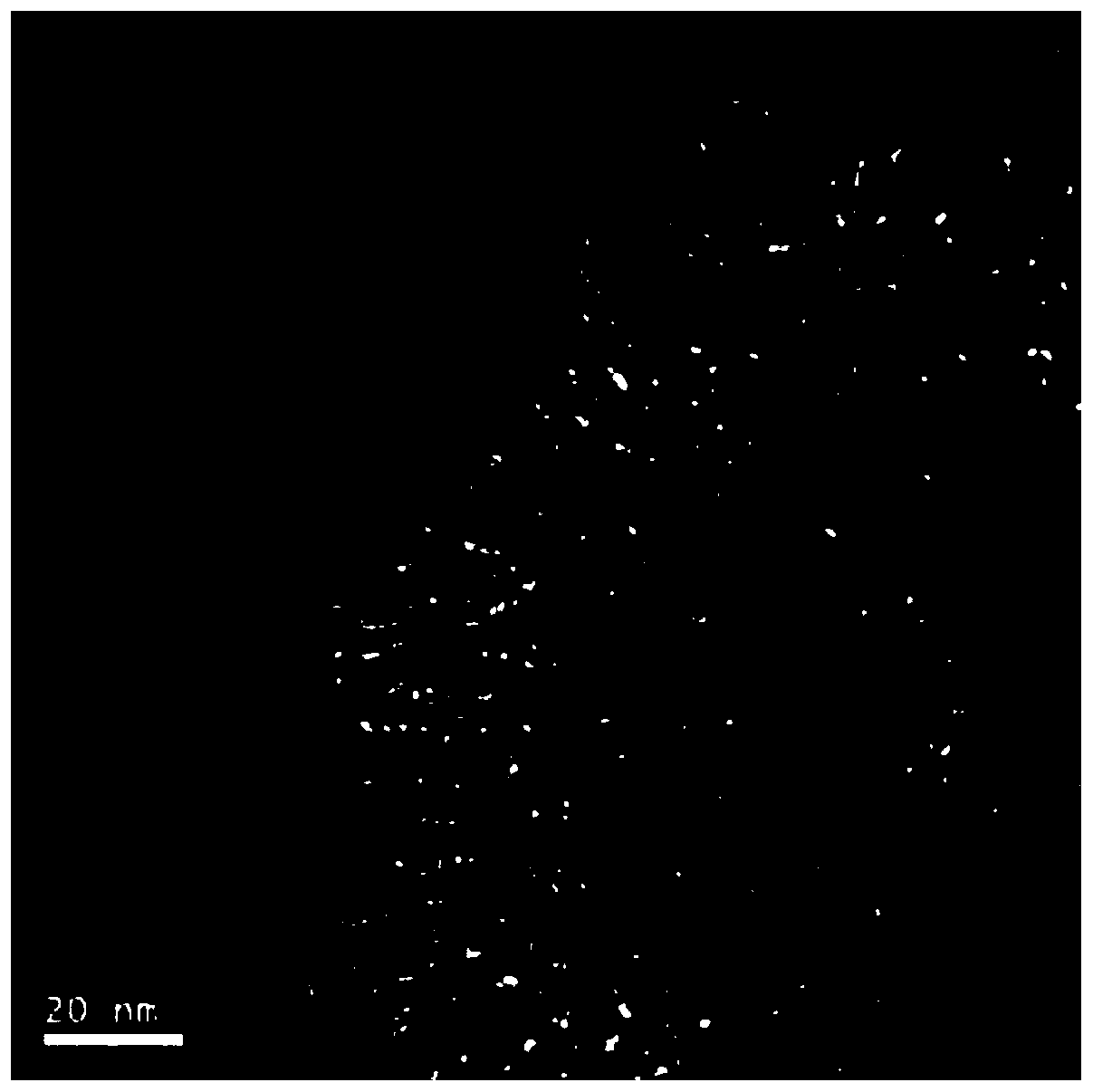

[0034] (1) Evenly disperse 50mg of γ-iron sesquioxide particles with a size of about 60nm in 100ml of water, 0.5g of 1,3,5-trimethylbenzene, 1g of L-lysine and 0.5g of Brij35 (C 12 h 25 EO 23 ) solution, after stirring for 30 minutes, add 2 g of tetraethyl orthosilicate (TEOS) dropwise, and stir at 50°C for 24 hours to obtain magnetic nanoparticles / silica containing pore-enlarging agent and surfactant Core-shell composite microspheres, the thickness of the pore expander / surfactant / silica composite coating layer is 100nm; the product is collected with a magnet, and washed three times with 0.6wt% ammonium nitrate ethanol solution;

[0035] (2) The above-mentioned washed magnetic nanoparticles / silica core-shell composite microspheres containing pore expanders and surfactants were calcined at 200°C for 9 hours in an air atmosphere to obtain γ-ferric oxide@mesoporous dioxide Silicon core-shell composite microspheres.

Embodiment 3

[0037] (1) 50mg of CoFe with a size of about 600nm 2 o 4 The particles are uniformly dispersed in 100ml of water, 1.5g of 1,3,5-trimethylbenzene, 0.05g of triethanolamine and 1g of small molecule Brij56 containing polyether (C 16 h 33 EO 10 ) solution, after stirring for 30 minutes, add 0.5g of sodium silicate dropwise, and stir at 80°C for 12 hours to obtain magnetic nanoparticles / silica core-shell composite microspheres containing pore expanders and surfactants , the thickness of the pore expander / surfactant / silicon dioxide composite coating layer is 20nm; the product is collected with a magnet, and washed three times with a hydrochloric acid ethanol solution with a pH greater than 1.0;

[0038] (2) Calcining the above-mentioned washed magnetic nanoparticles / silica core-shell composite microspheres containing pore expanders and surfactants at 500 °C for 1 h in an air atmosphere to obtain CoFe 2 o 4 @Mesoporous silica core-shell composite microspheres.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com