Extraction method of valuable metal in copper anode mud

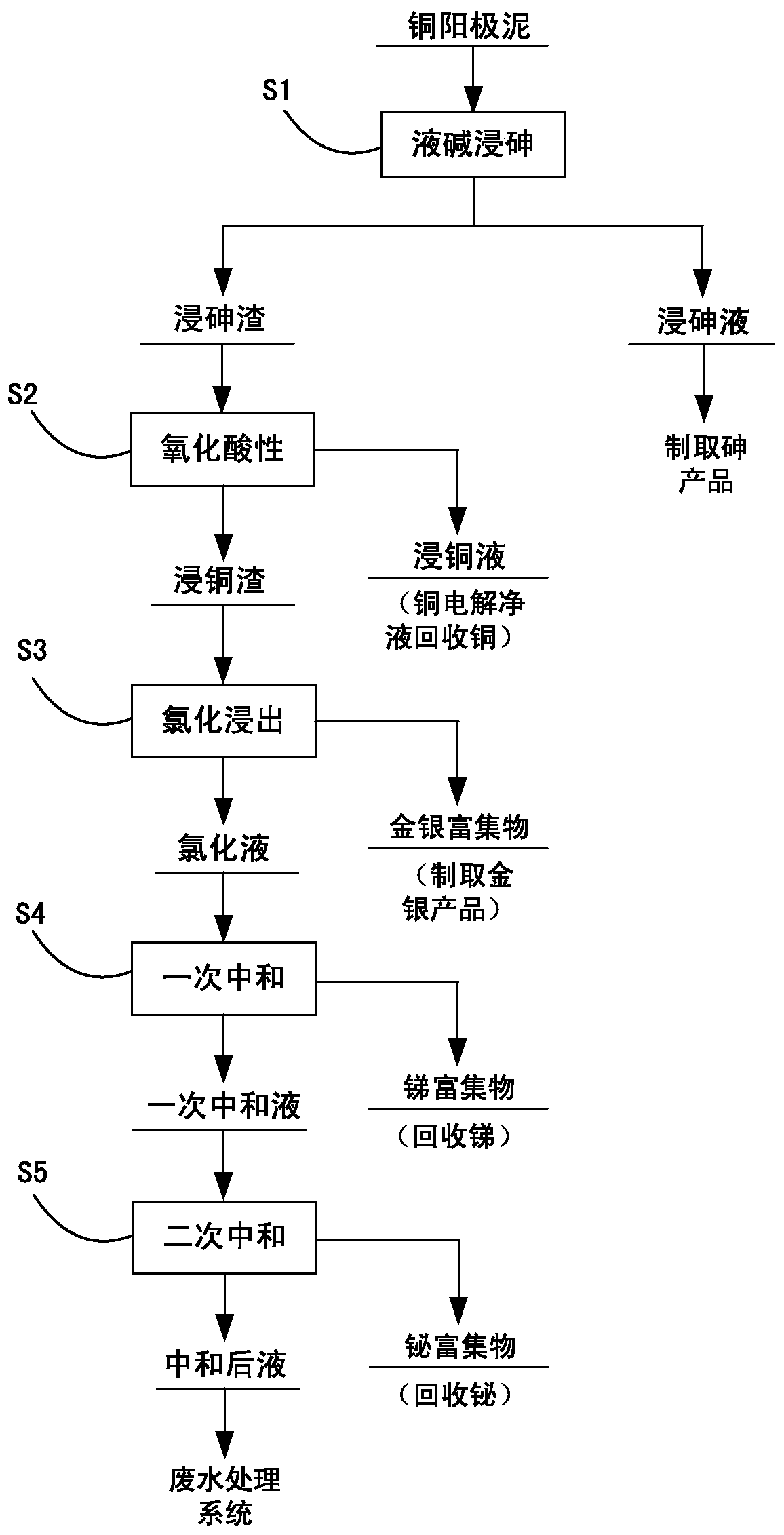

An extraction method, copper anode slime technology, which is applied in the field of non-ferrous metallurgy, can solve the problems of long process flow and complicated operation, and achieve the effect of short process flow, simple operation and effective recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] The main components of copper anode slime are (%) by weight: Cu 21.35, As 5.34, Au 0.35, Ag 8.96, Te1.60, Se 4.80, Pb 8.14, Sb 4.85, Bi 2.21.

[0039] Prepare a sodium hydroxide solution with a concentration of 50g / L, add copper anode slime to the prepared sodium hydroxide solution at a liquid-to-solid ratio of 6:1, control the reaction temperature at 85°C, stir for 4 hours, and arsenic is leached into the solution. Filter to obtain arsenic immersion solution and arsenic leaching residue. The arsenic leaching solution contains 8.82g / L arsenic, and the arsenic leaching rate is 99.02%.

[0040] The arsenic leaching slag is added to the sulfuric acid solution according to the liquid-solid ratio of 6:1, the acidity of the initial reaction sulfuric acid is 350g / L, and the blowing intensity is 0.6kg / cm 3 , the reaction temperature was 65°C, the reaction oxidation potential was controlled at 380mv, and stirred for 10h. Filter, leaching copper solution and leaching copper sla...

Embodiment 2

[0045] The main components of copper anode slime are (%) by weight: Cu 19.85, As 5.86, Au 0.32, Ag 8.01, Te1.24, Se 3.65, Pb 8.95, Sb 4.79, Bi 2.36.

[0046] Prepare a sodium hydroxide solution with a concentration of 60g / L, add copper anode slime to the prepared sodium hydroxide solution at a liquid-to-solid ratio of 5:1, control the reaction temperature at 85°C, stir for 4 hours, and arsenic is leached into the solution. Filter to obtain arsenic immersion solution and arsenic leaching residue. The arsenic leaching solution contained 11.58g / L of arsenic, and the arsenic leaching rate was 98.81%.

[0047] The arsenic leaching slag is added to the sulfuric acid solution according to the liquid-solid ratio of 6:1. The acidity of the initial reaction sulfuric acid is 350g / L, the blowing intensity is 0.5kg / cm3, the reaction temperature is 70°C, the reaction oxidation potential is controlled at 400mv, and stirred for 10h. Filter, leaching copper solution and leaching copper slag. ...

Embodiment 3

[0052] The main components of copper anode slime are (%) by weight: Cu 12.58, As 7.89, Au 0.38, Ag 9.48, Te2.03, Se 5.64, Pb 10.12, Sb 9.85, Bi 7.55.

[0053] Prepare a sodium hydroxide solution with a concentration of 60g / L, add copper anode slime to the prepared sodium hydroxide solution at a liquid-to-solid ratio of 5:1, control the reaction temperature at 85°C, stir for 4 hours, and arsenic is leached into the solution. Filter to obtain arsenic immersion solution and arsenic leaching residue. The arsenic leaching solution contains 15.63g / L arsenic, and the arsenic leaching rate is 99.05%.

[0054] The arsenic leaching slag is added to the sulfuric acid solution according to the liquid-solid ratio of 6:1. The acidity of the initial reaction sulfuric acid is 350g / L, the blowing intensity is 0.5kg / cm3, the reaction temperature is 70°C, the reaction oxidation potential is controlled at 400mv, and stirred for 10h. Filter, leaching copper solution and leaching copper slag. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com