Material tray used for thermal treatment of special-shaped cutter plates

A technology of blade and material used in heat treatment furnaces, heat treatment equipment, furnaces, etc., can solve the problems of ineffective stress release, increase production costs, cracking of material trays, etc., achieve weak ductility, prolong service life, Reduce blocking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the content of the present invention more clearly understood, the present invention will be further described in detail below based on the specific embodiments and in conjunction with the accompanying drawings.

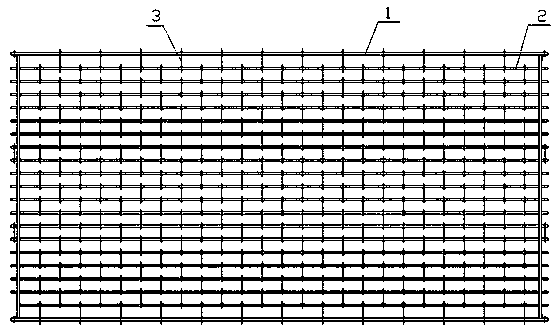

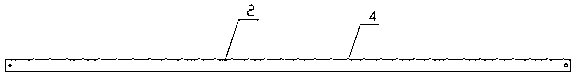

[0025] This embodiment provides a tray for heat treatment of special-shaped blades, including an outer frame 1 and several rib plates 2 arranged in the outer frame 1, see figure 1 , the tray is rectangular, the length of the tray is 4000mm, and the width of the tray is 2000mm. Several ribs 2 in the outer frame 1 are arranged along the length direction of the tray, and the distance between adjacent ribs 2 and the distance between the outer frame 1 and adjacent ribs 2 are equal. Between the adjacent ribs 2 and between the outer frame 1 and the adjacent ribs 2, bolts 3 are alternately installed, and the bolts 3 are arranged perpendicular to the length direction of the ribs 2, see figure 1 .

[0026] Among them, the outer frame 1 of the tray and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com