Polyurethane-polyurea aqueous dispersion, as well as preparation method and application in water-based wood coating thereof

A technology of polyurethane and dispersion, applied in the direction of polyurea/polyurethane coatings, coatings, etc., can solve the problems of unrecorded water-based resin preparation and characteristics, and focus on the combination of coating formulas, so as to improve the effect of warming wood, improve drying speed and cross-linking The effect of increasing the joint density and improving the hole penetration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

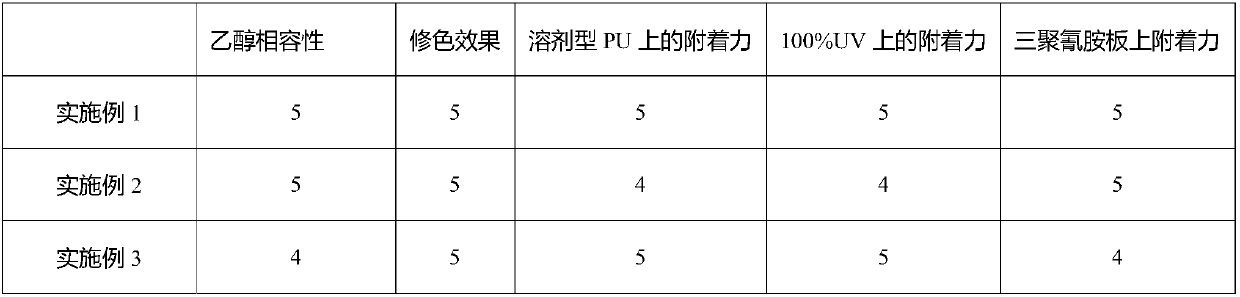

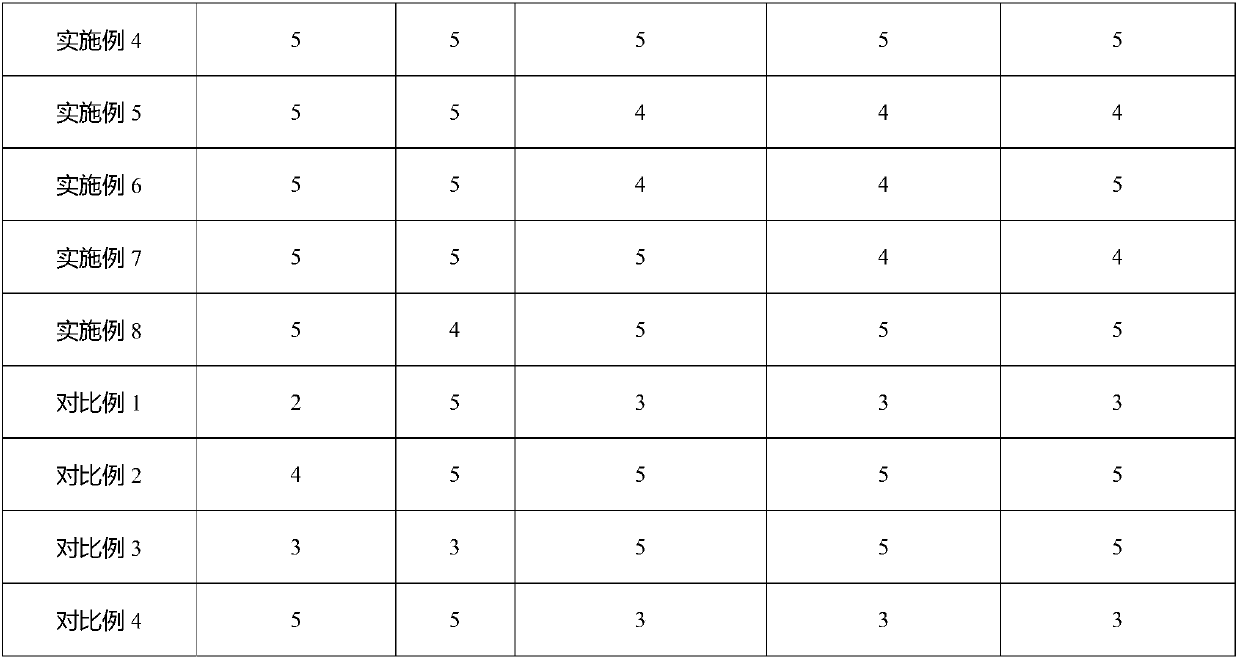

Examples

Embodiment 1

[0089] 100g dehydrated polycaprolactone diol, 100g glycerin modified soybean oil, 5g polyethylene glycol monomethyl ether, 15g polyoxypropylene trihydric alcohol WANOL R2305, 95g TDI-80, 25g HMDI and 65g acetone Add it into a 1L four-neck round-bottom flask equipped with a nitrogen inlet and outlet, and stir the mixture at 80-90° C. until the NCO reaches 7.0 wt%. Cool down to 50-55°C, add 4g of 1,4-butanediol, 12g of 2,2-dimethylolpropionic acid (DMPA), and 75g of acetone, raise the temperature to 60°C and continue the reaction until the NCO reaches 2.35wt%. Cool down to 40-45°C and add 7.3g of triethylamine to neutralize for about 5 minutes, then add 700g of water to disperse the mixture, add 4.1g of ethylenediamine after the dispersion and continue to stir and extend the chain for 10 minutes. After separation of the acetone by distillation, a solvent-free dispersion was obtained which had a solids content of 35% by weight, an average particle size of 165 nm and a pH value of...

Embodiment 2

[0091] 110g glycerin modified soybean oil, 5g polyethylene glycol monomethyl ether, 35g polyoxypropylene trihydric alcohol WANOLR2305, 120g TDI-80 and 65g acetone were added in a 1L four-necked round bottom flask equipped with a nitrogen inlet and outlet, The mixture was stirred at 80-90°C until NCO reached 11.1 wt%. Cool down to 50-55°C and add 6g of 1,4-butanediol, 12g of 2,2-dimethylolpropionic acid (DMPA), 75g of acetone, raise the temperature to 60°C and continue the reaction until the NCO reaches 2.50wt%. Cool down to 40-45°C and add 8.2g of triethylamine to neutralize for about 5 minutes, then add 592g of water to disperse the mixture, add 3.8g of ethylenediamine after the dispersion and continue stirring for 10 minutes to extend the chain. After separation of the acetone by distillation, a solvent-free dispersion was obtained which had a solids content of 35% by weight, an average particle size of 105 nm and a pH of 8.5.

Embodiment 3

[0093] Add 110g of glycerin modified soybean oil, 3g of polyethylene glycol monomethyl ether, 40g of polyoxypropylene trihydric alcohol WANOLS3007, 163g of HMDI65g of acetone into a 1L four-neck round-bottomed flask equipped with a nitrogen inlet and outlet. The mixture was stirred at °C until the NCO reached 8.0 wt%. Lower the temperature to 50-55°C and add 16g of 2,2-dimethylolpropionic acid (DMPA) and 75g of acetone, then raise the temperature to 60°C and stir to continue the reaction until the NCO reaches 2.0wt%. Cool down to 40-45°C and add 9.7g triethylamine to neutralize for about 5min, then disperse the mixture by adding 564g water, and then separate the acetone by distillation to obtain a solvent-free dispersion with a solid content of 30.8wt%. The average particle size is 90nm and the pH value is 8.5.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com