Calcium sulfate-doped high-performance fiber cement-based composite material and preparation method thereof

A high-performance fiber and composite material technology, applied in the field of cement materials, can solve the problems of low matrix strength and achieve the effects of improving interface performance, reducing carbon emissions, and good toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

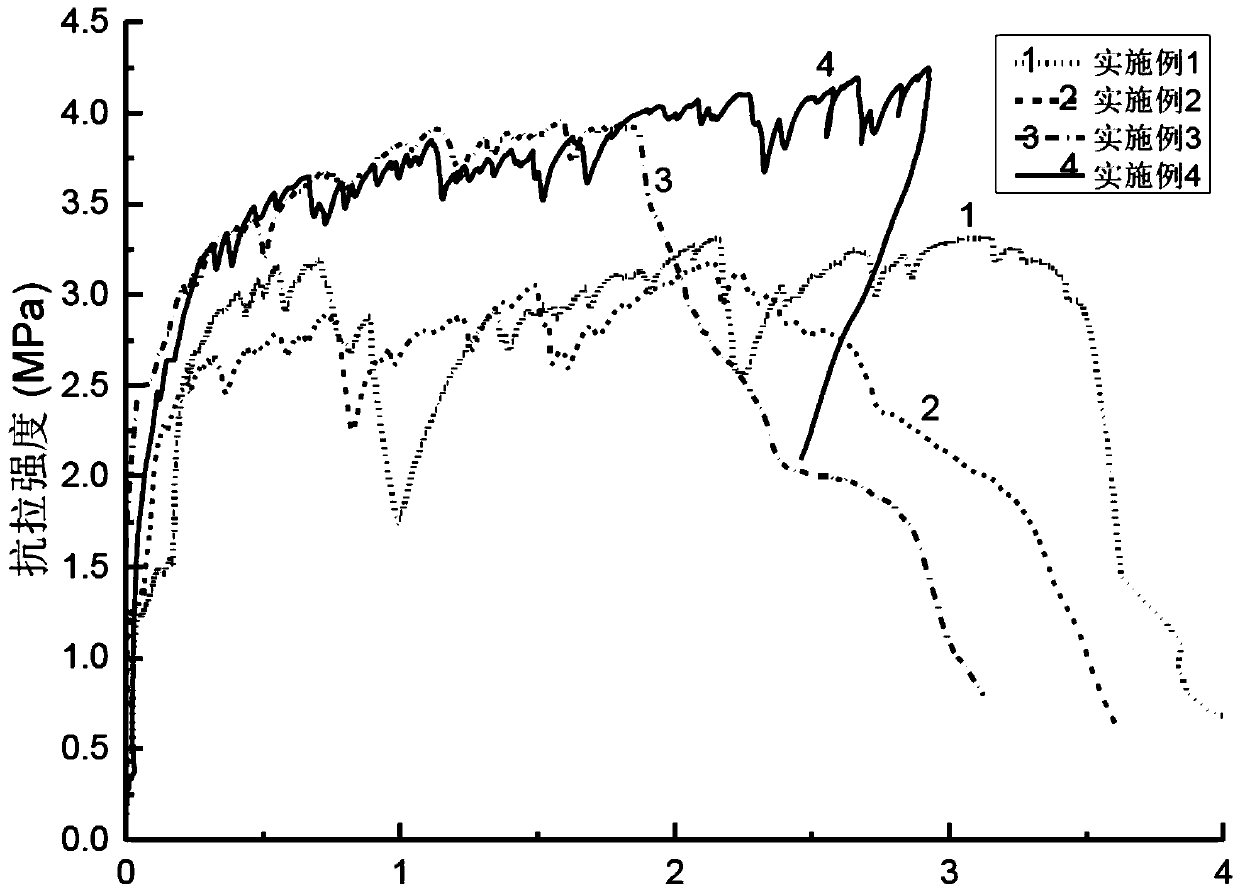

Examples

Embodiment 1

[0038] A high-performance fiber cement-based composite material mixed with calcium sulfate in the present invention, calculated by mass parts, the composition and content of raw materials in the composite material are as follows:

[0039] Cement: 500.1 parts

[0040] Fly ash: 1083.5 parts

[0041] Silica fume: 83.3 parts

[0042] Quartz sand: 600.1 parts

[0043] Calcium sulfate: 33.3 parts

[0044] Water: 450.1 parts

[0045] Water reducing agent: 15.2 parts

[0046] Thickener: 1 part

[0047] PVA fiber: 39.3 parts

[0048] The cement described in the examples is ordinary Portland cement of strength grade 42.5.

[0049] The fly ash described in the examples is primary fly ash.

[0050] The silica fume described in the examples is silica fume with a silicon content of 94wt%.

[0051] The quartz sand described in the embodiment is 80-120 mesh quartz sand.

[0052] Calcium sulfate described in the embodiment is calcium sulfate dihydrate whisker-like powder.

[0053] T...

Embodiment 2

[0064] A high-performance fiber cement-based composite material mixed with calcium sulfate in the present invention, calculated by mass parts, the composition and content of raw materials in the composite material are as follows:

[0065] Cement: 500.1 parts

[0066] Fly ash: 1083.5 parts

[0067] Silica fume: 83.3 parts

[0068] Quartz sand: 600.1 parts

[0069] Calcium sulfate: 66.6 parts

[0070] Water: 450.1 parts

[0071] Water reducing agent: 15.2 parts

[0072] Thickener: 1 part

[0073] PVA fiber: 39.3 parts

[0074] Other implementation content and steps are the same as embodiment 1.

[0075] The mechanical test results of the specimens obtained in this embodiment are shown in Table 2. The specimens were cured in a standard manner, and the curing age was 28 days.

[0076] Table 2: The mechanical performance test results of the specimens obtained in Example 2

[0077]

Embodiment 3

[0079] A high-performance fiber cement-based composite material mixed with calcium sulfate in the present invention, calculated by mass parts, the composition and content of raw materials in the composite material are as follows:

[0080] Cement: 750.1 parts

[0081] Fly ash: 833.4 parts

[0082] Silica fume: 83.3 parts

[0083] Quartz sand: 600.1 parts

[0084] Calcium sulfate: 33.3 parts

[0085] Water: 416.8 parts

[0086] Water reducing agent: 18 parts

[0087] Thickener: 1 part

[0088] PVA fiber: 38.4 parts

[0089] Other implementation content and steps are the same as embodiment 1.

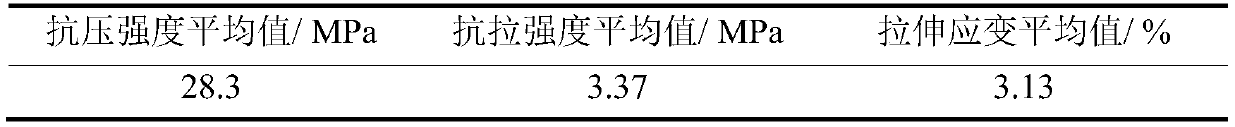

[0090] The mechanical test results of the test piece obtained in this embodiment are shown in Table 3, and the test piece adopts standard curing, and the curing age is 28 days.

[0091] Table 3: The mechanical performance test results of the specimens obtained in Example 3

[0092]

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com