Drum type cleaning and pre-cooling treatment method and equipment after stone fruits are harvested in edge of field

A post-harvest processing and stone fruit technology, which is applied to the preservation of fruits/vegetables by freezing/refrigeration, food processing, chemical instruments and methods, etc. Handling and other problems to achieve the effect of equipment safety, stability and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

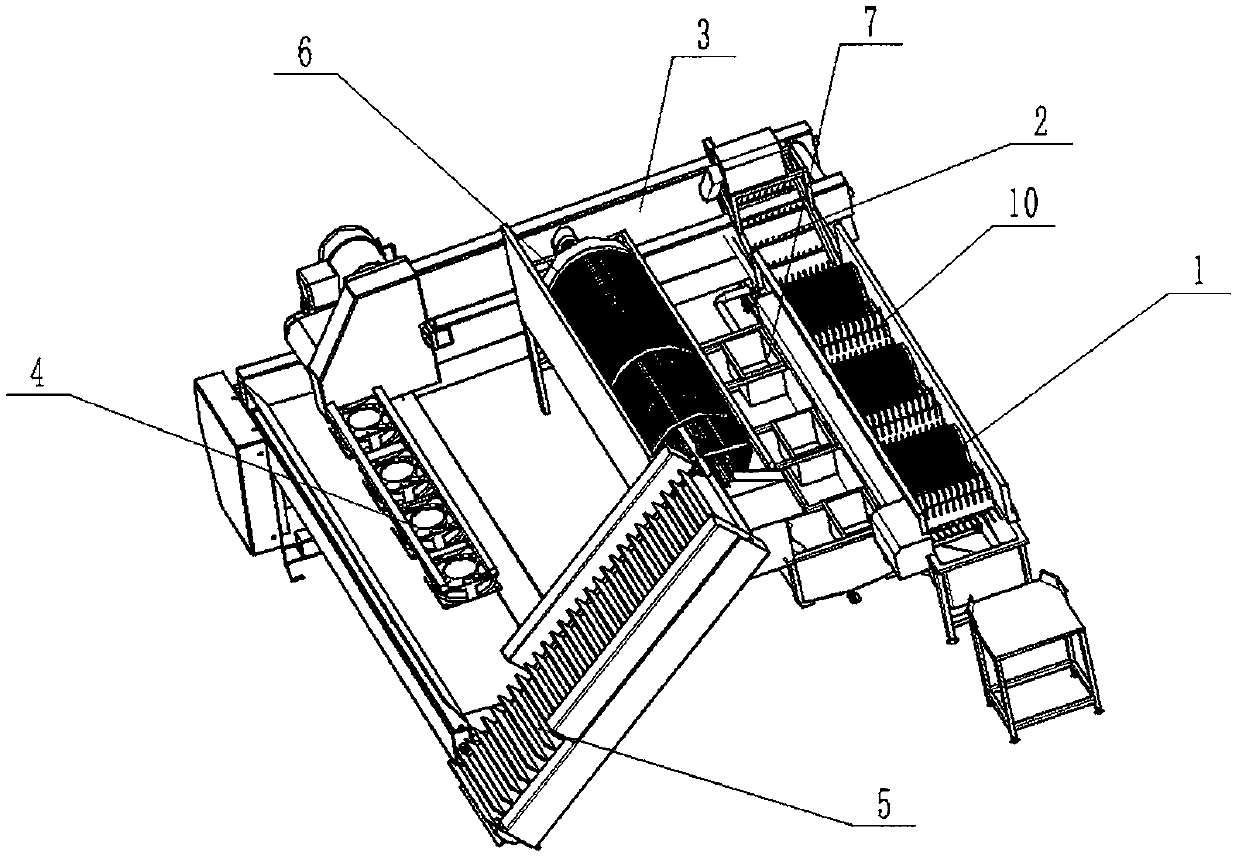

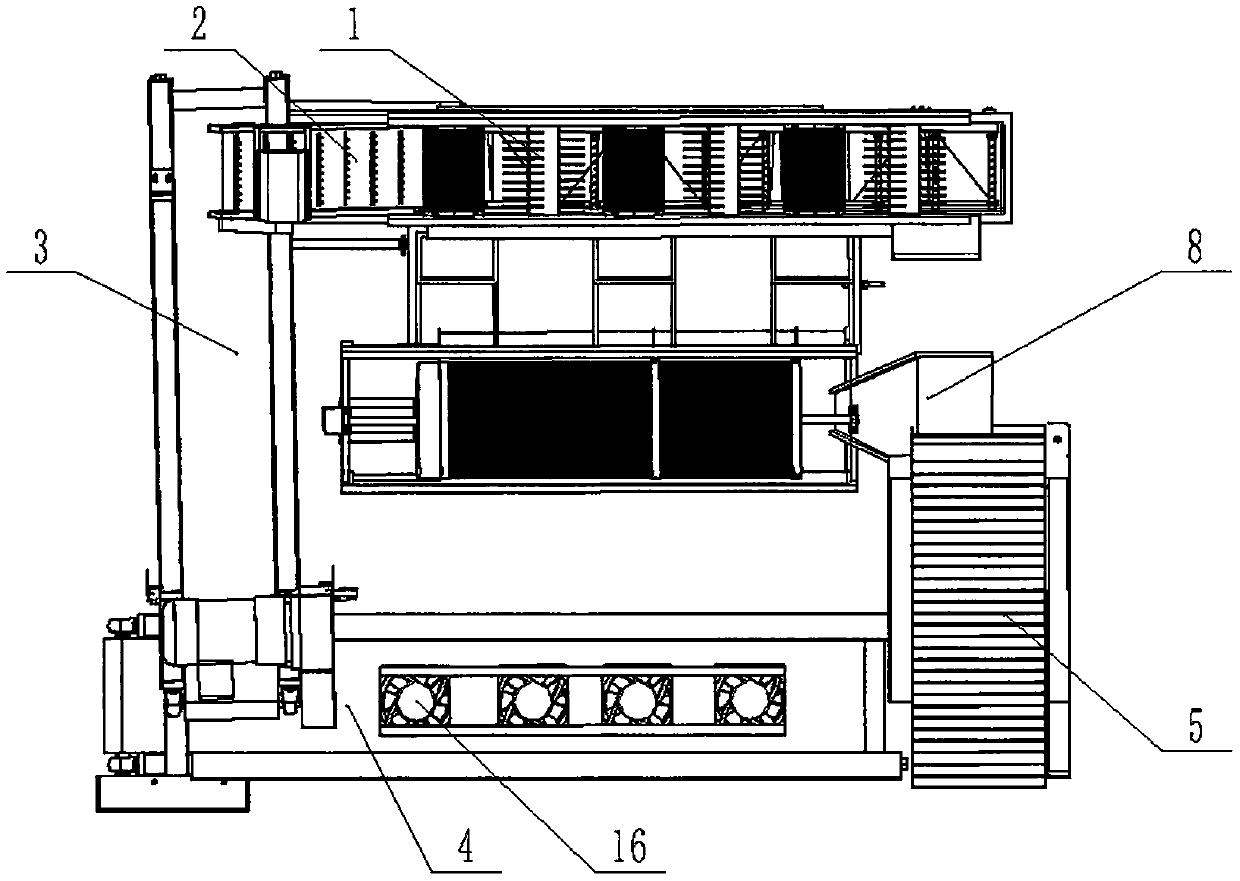

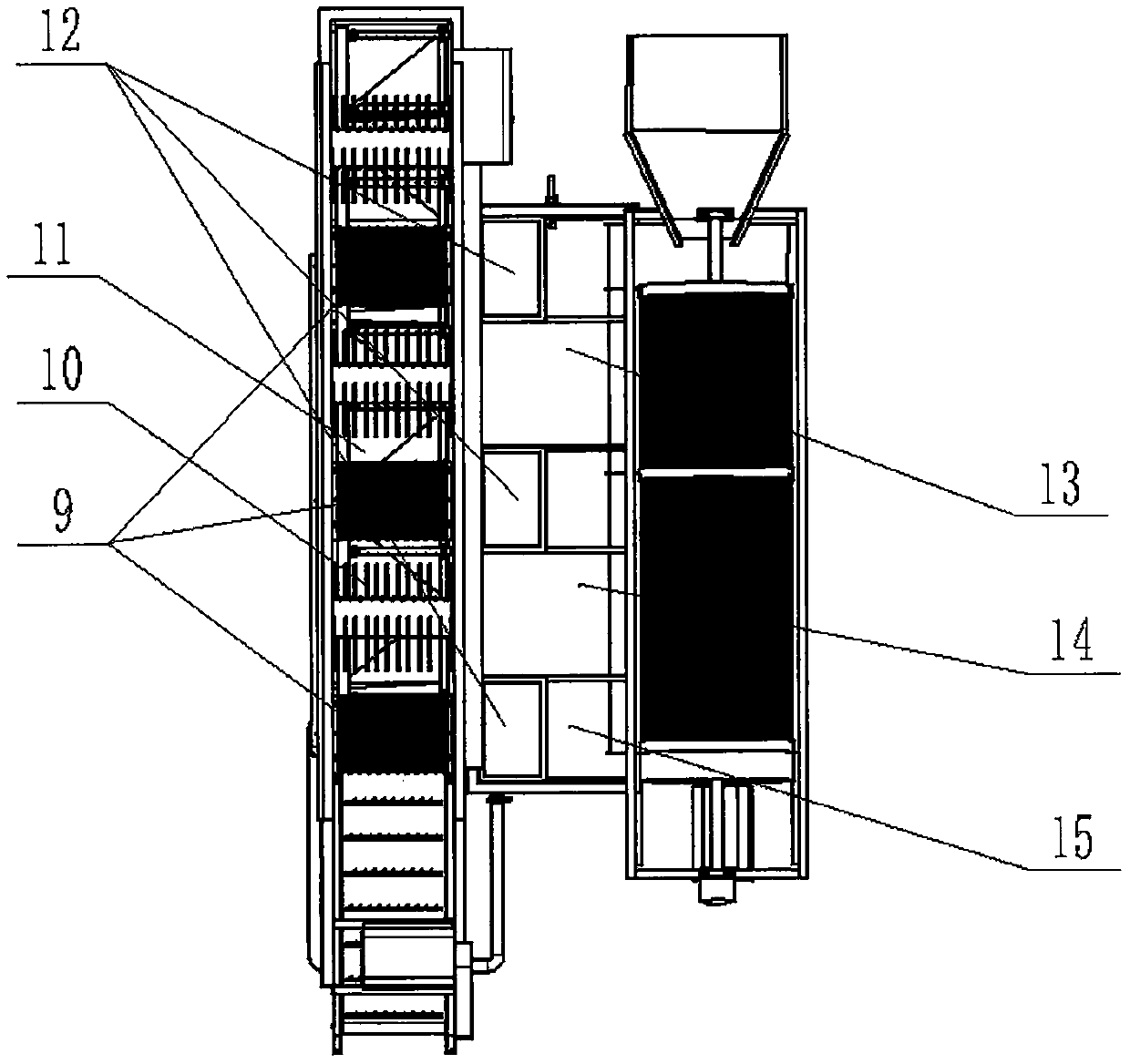

[0027] With the goal of immediate post-harvest treatment of stone fruits, the mechanized post-harvest treatment of stone fruit fields is carried out by adopting the technological process of pre-cooling, impurity cleaning-manual sorting-air-drying-lifting-grading-impurities, and product centralized treatment.

[0028] Pre-cooling and impurity cleaning: Pre-cool the picked fruits immediately, and put the picked fruits directly into the pre-cooling cleaning tank 1. The pre-cooling cleaning tank 1 is mixed with ice-water mixture. The pre-cooling cleaning tank 1 in the form of a production line The transfer fork 10 has the function of conveying the fruit, ensuring that the pre-cooling time of the fruit is 3 to 15 minutes; the cleaning roller 9 of the pre-cooling cleaning tank 1 can separate the branches and leaves and discharge them o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com