Wood fiber/tencel cashmere imitation double-layer fabric

A double-layer fabric and wood fiber technology, applied in fiber treatment, plant fiber, biochemical fiber treatment, etc., can solve the problems of cashmere fabrics such as poor moisture permeability, poor air permeability, and easy moth-eaten property, and achieve anti-pilling Good, high comfort, realistic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

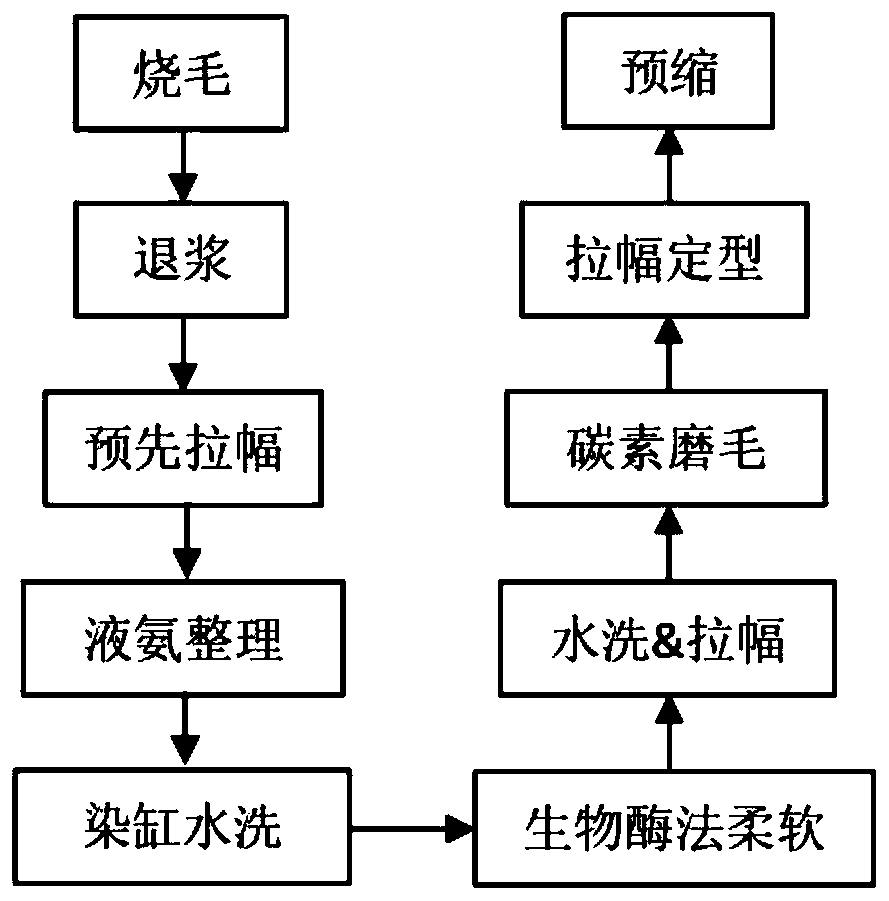

Method used

Image

Examples

Embodiment 1

[0024] A wood fiber / tencel imitation cashmere double-layer fabric, the fabric is a double-weft double-sided fabric, the warp yarn is made of 100% long-staple cotton high-count warp yarn, and the inner weft is made of long-staple cotton / wood fiber 50S high-count mixed fabric For spinning, long-staple cotton / Tencel 50S / 2 blended strands are used for the surface and weft, the blending ratio of the blended yarn is 50% long-staple cotton and 50% wood fiber, the basis weight of the roving is 4.01g / 10m, and the basis weight of the spun yarn is 0.645g / 100m , twist 1319T / m, speed 15 000r / min, roller diameter 25×25×25mm, roller gauge 18×39mm.

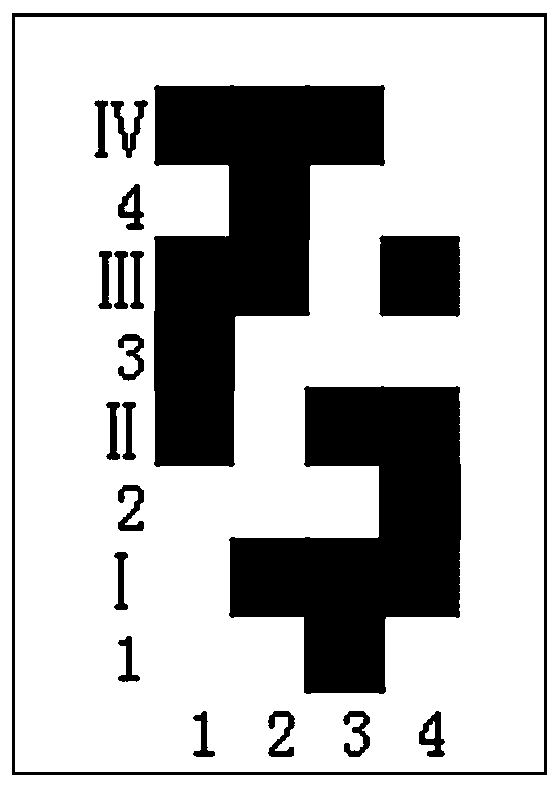

[0025] The fabric adopts 1 / 3+3 / 1 double-sided twill weave, the surface weave is 1 / 3 right twill, and the inner weave is 3 / 1 right twill. host.

[0026] The warp of the fabric is gray, the surface weft is gray-green, and the inner weft is light gray. The combination of gray and gray-green makes the surface texture present a layered green tone.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com