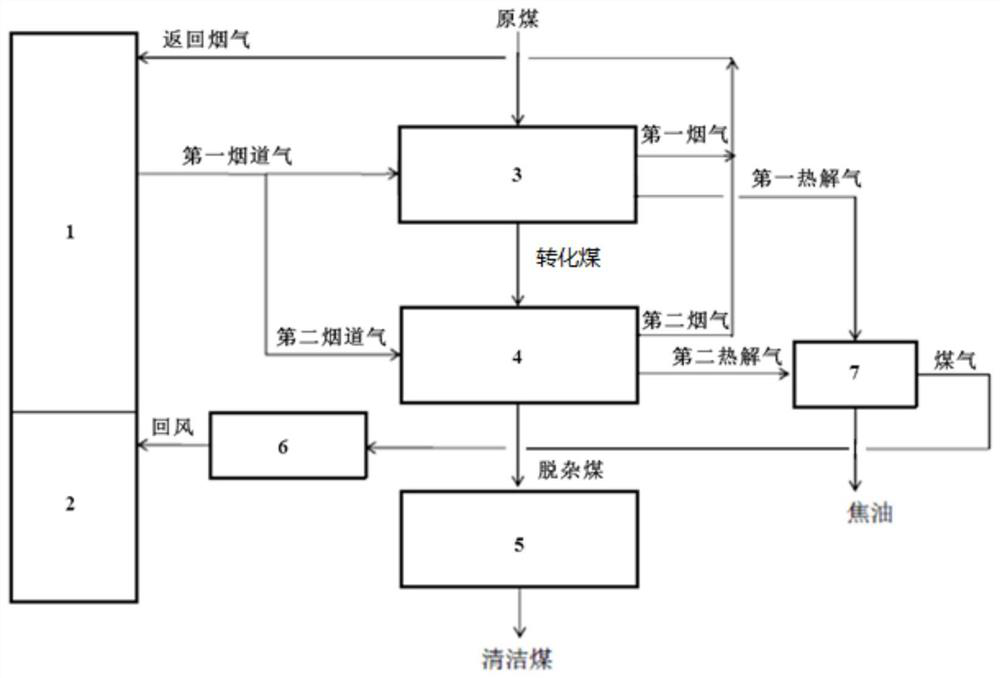

Method and system for producing clean coal by coupling power generation in a power plant

A power plant, clean technology, applied in steam generation method using heat carrier, lighting and heating equipment, fuel, etc., to achieve the effect of stabilizing furnace temperature, reducing pollutant emission and simplifying production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

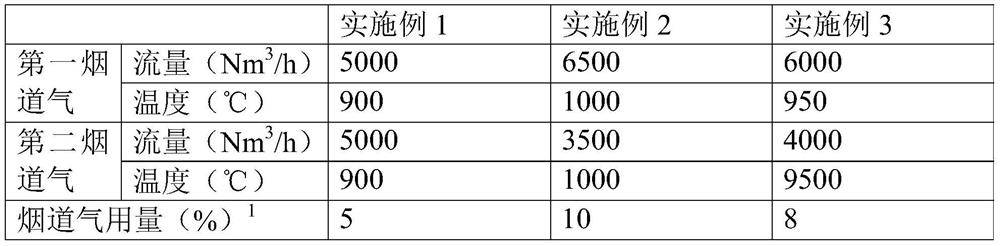

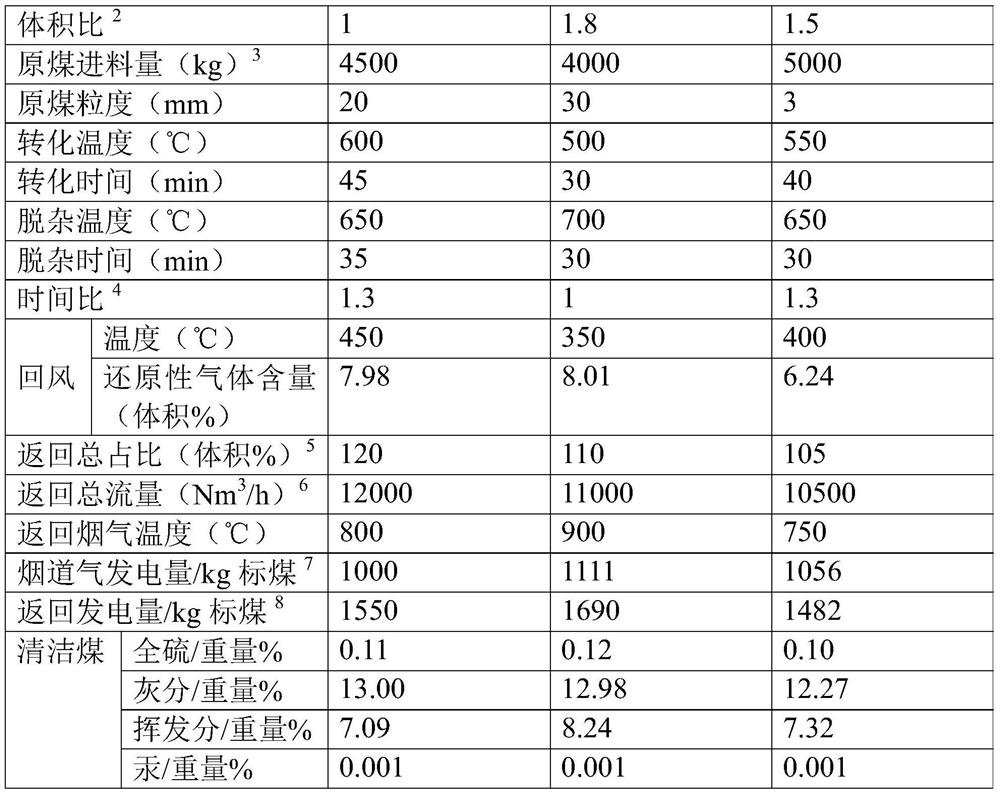

Embodiment 1

[0068] (1) put 5000Nm 3 / h of the first flue gas (900°C) indirectly heats 4,500kg of raw coal (lignite, with a particle size of 20mm) in the rotary kiln for 45 minutes of coal conversion, and the final conversion temperature is 600°C to obtain the first flue gas, the first pyrolysis gas and converted coal;

[0069] (2) put 5000Nm 3 / h of the second flue gas (900°C) indirectly heats the converted coal in the rotary kiln to remove impurities for 35 minutes. ;

[0070] (3) dry-cooling the de-miscellaneous coal to obtain clean coal;

[0071] (4) After the first and second pyrolysis gases are combined, tar is removed to obtain a tar product; at the same time, coal gas is obtained as return air (temperature 450° C.), which is returned to the burner of the power plant boiler through the induced draft device for power generation; The first and second flue gas are merged into return flue gas (800°C) and sent to the power plant boiler for power generation; the total flow of return a...

Embodiment 2

[0075] (1) Use 6500Nm 3 / h of the first flue gas (1000°C) indirectly heats 4000kg of raw coal (non-caking coal, particle size: 30mm) in the tower moving bed to carry out coal conversion for 30min, and the final conversion temperature is 500°C to obtain the first flue gas, first pyrolysis gas and converted coal;

[0076] (2) Use 3500Nm 3 / h of the second flue gas (1000°C) indirectly heats the converted coal in the rotary kiln to remove impurities for 30 minutes, and the final removal temperature is 700°C to obtain the second flue gas, the second pyrolysis gas and the coal;

[0077] (3) dry-cooling the de-miscellaneous coal to obtain clean coal;

[0078](4) After the first and second pyrolysis gases are combined, tar is removed to obtain tar products; at the same time, coal gas is obtained as return air (temperature 350 ° C) and returned to the burner of the power plant boiler through the induced draft device for power generation; the first Combined with the second flue gas,...

Embodiment 3

[0082] (1) Use 6000Nm 3 / h of the first flue gas (950°C) indirectly heats 5000kg of raw coal (long-flame coal, particle size: 3mm) in the tower-type moving bed, and carries out coal conversion for 40min, and the final conversion temperature is 550°C, and the first flue gas, first pyrolysis gas and converted coal;

[0083] (2) with 4000Nm 3 The first flue gas (9500°C) in the rotary kiln indirectly heats the converted coal in the rotary kiln for 30 minutes of coal removal, and the final removal temperature is 650°C to obtain the second flue gas, the second pyrolysis gas and the removal of impurities coal;

[0084] (3) dry-cooling the de-miscellaneous coal to obtain clean coal;

[0085] (4) After the first and second pyrolysis gases are combined, tar is removed to obtain tar products; at the same time, coal gas is obtained as return air (temperature 400 ° C) and returned to the burner of the power plant boiler through the induced draft device for power generation; the first C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com