Ionic conductor elastomer and preparation and application thereof

A technology of ion conductors and elastomers, applied in the direction of additive processing, etc., can solve the problems of long self-healing effect and inability to take into account stability, etc., and achieve the effects of easy batch production, self-repairing elongation at break, and convenient operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] 5 g of 3-(2-methacryloxyethyl dimethylamino) propanesulfonate monomer, 1.3 g of polyacrylic acid and 2.1 g of 1-ethyl-3-methylimidazole ethyl sulfate salt were dispersed In 30mL of water, stir evenly; add 0.1g of ammonium persulfate initiator; mix the aqueous solution and heat it at 70°C for 6 hours, and the obtained polymer aqueous solution is dried at room temperature to form a film, or processed into various shapes by 3D printing, A high-strength, self-healing, ultra-long stretchable ion conductor elastomer at room temperature can be obtained.

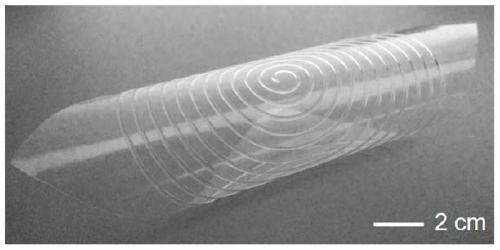

[0034] The tensile curve of the ion conductor elastomer obtained in this embodiment is as follows figure 1 The mechanical data are shown in Table 1. From figure 1 As can be seen in Table 1, the ionic conductor elastomer has a Young's modulus of 2.3 MPa, an elongation at break of more than 10000%, and a rapid room temperature self-healing effect.

[0035] Table 1 The mechanical data of the ion-conducting elastomer prepare...

Embodiment 2

[0041]Disperse 2 g of 3-(2-methacryloyloxyethyldimethylamino)propanesulfonate monomer, 1.3 g of polyacryl alcohol and 3 g of 1-butyl-3-methylimidazolium tetrafluoroborate In 10mL of water, stir evenly; add 0.5g of potassium persulfate initiator; mix the aqueous solution and heat reaction at 50°C for 24 hours, and the obtained polymer aqueous solution is dried at room temperature to form a film, or processed into various shapes by 3D printing, A high-strength, self-healing, ultra-long stretchable ion conductor elastomer at room temperature can be obtained.

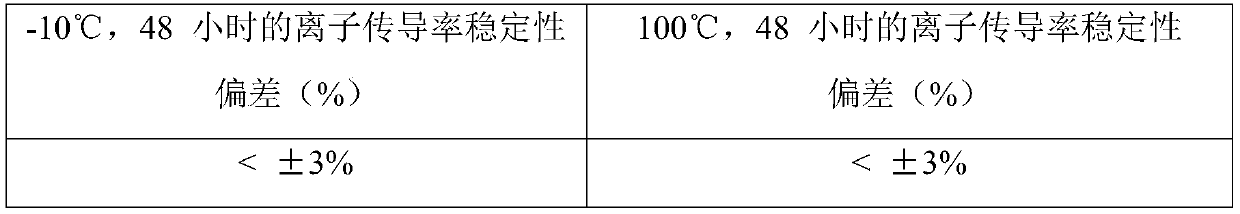

[0042] The ionic conductor elastomer prepared in this example has a Young's modulus of 1 MPa, an elongation at break of more than 2000%, and a rapid self-repair effect at room temperature (the self-repair time at room temperature is 36 hours, and the self-repair efficiency is close to 100%); Good ion conduction stability (deviation <±3%) can be maintained at extreme low temperature (-10°C) and extreme high temperature (100°...

Embodiment 3

[0044] Disperse 2g of acrylic acid monomer, 1.3g of acrylamide monomer, 1g of polyvinyl alcohol and 2.1g of 1-ethyl-3-methylimidazole ethyl sulfate salt in 10mL of water, stir well; add 1g of 2-hydroxy- Methylphenylpropan-1-one initiator; the mixed aqueous solution was subjected to UV (365nm, 200mW cm -2 ) light for 1 second, and the obtained polymer aqueous solution is dried at 100°C to form a film, or processed into various shapes by 3D printing, and a high-strength, self-healing, ultra-long stretchable ion conductor at room temperature can be obtained. elastomer.

[0045] The ionic conductor elastomer obtained in this example has a Young's modulus of 1.1 MPa, an elongation at break of more than 2000%, and a rapid self-repair effect at room temperature (the self-repair time at room temperature is 12h, and the self-repair efficiency is close to 100%) ; Good ion conduction stability (deviation <±3%) can be maintained at extreme low temperature (-10°C) and extreme high tempera...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com