System and method for dry filling of mined-out areas

A technology of goaf and dry method, applied in the direction of filling, mining equipment, mining equipment, etc., can solve the problems of low filling efficiency, unsuitable for large-scale modern mine large-scale filling and mining, and limited solid waste treatment capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

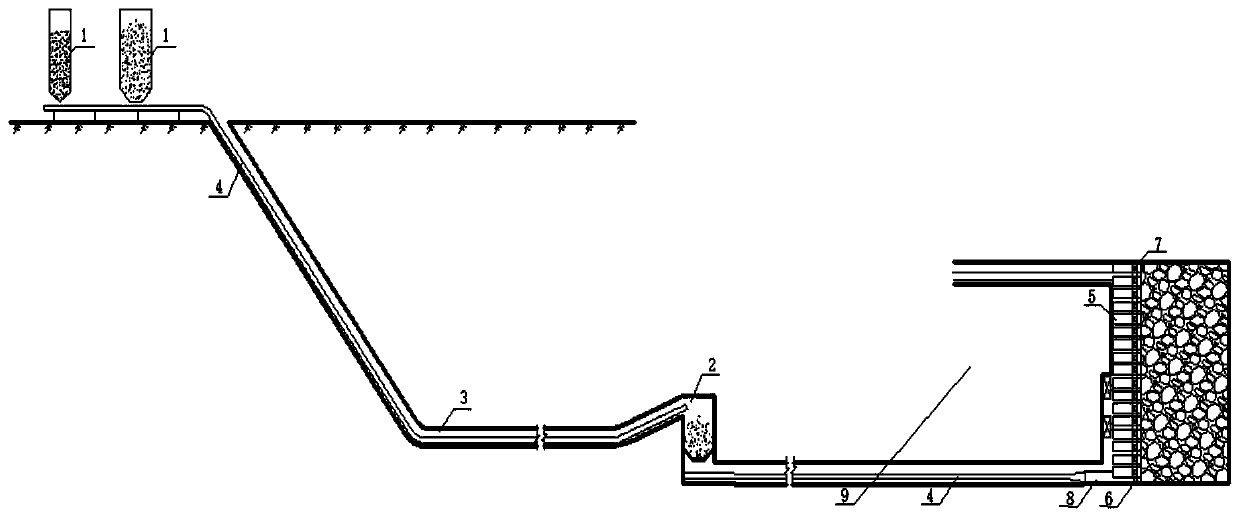

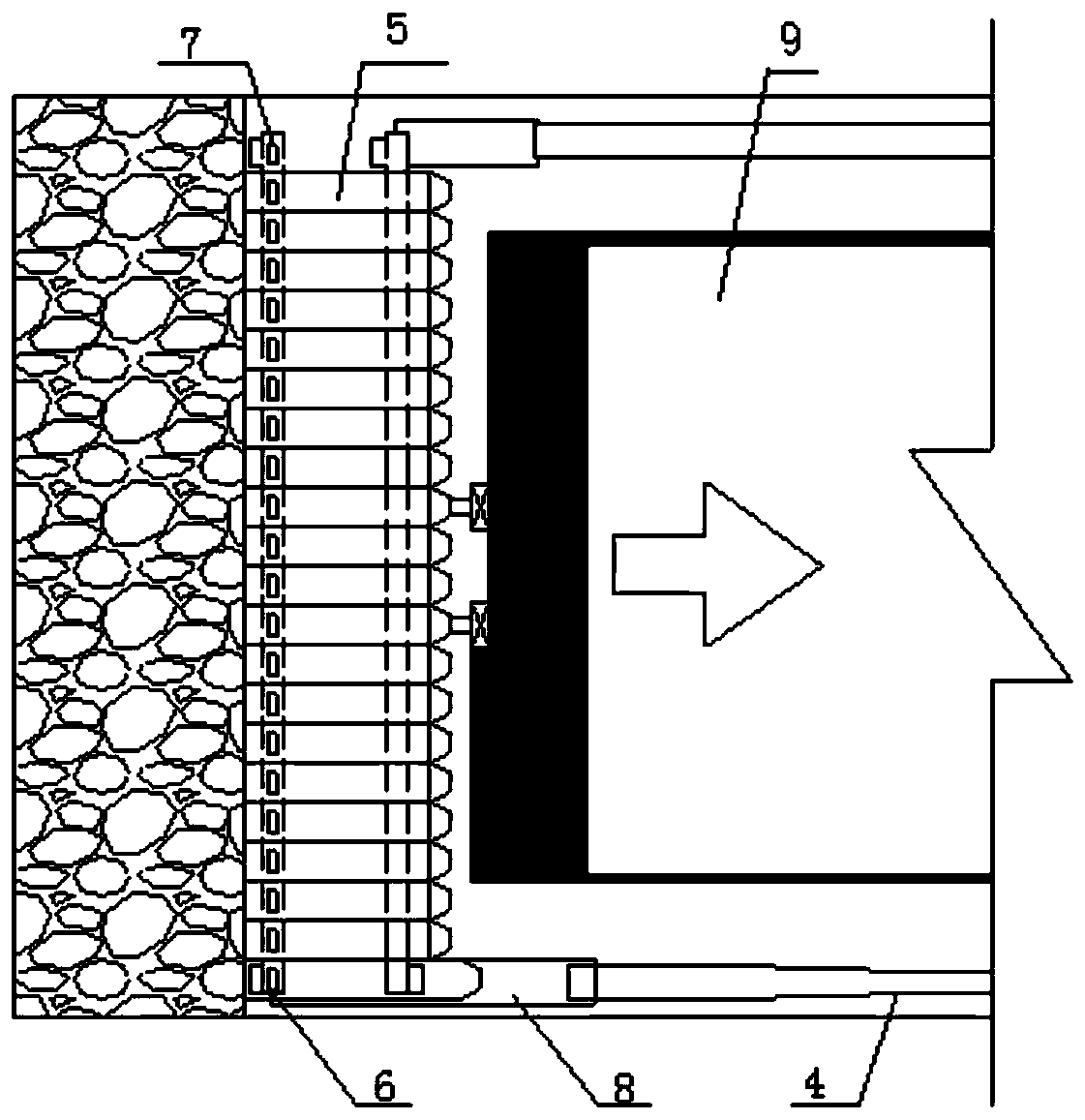

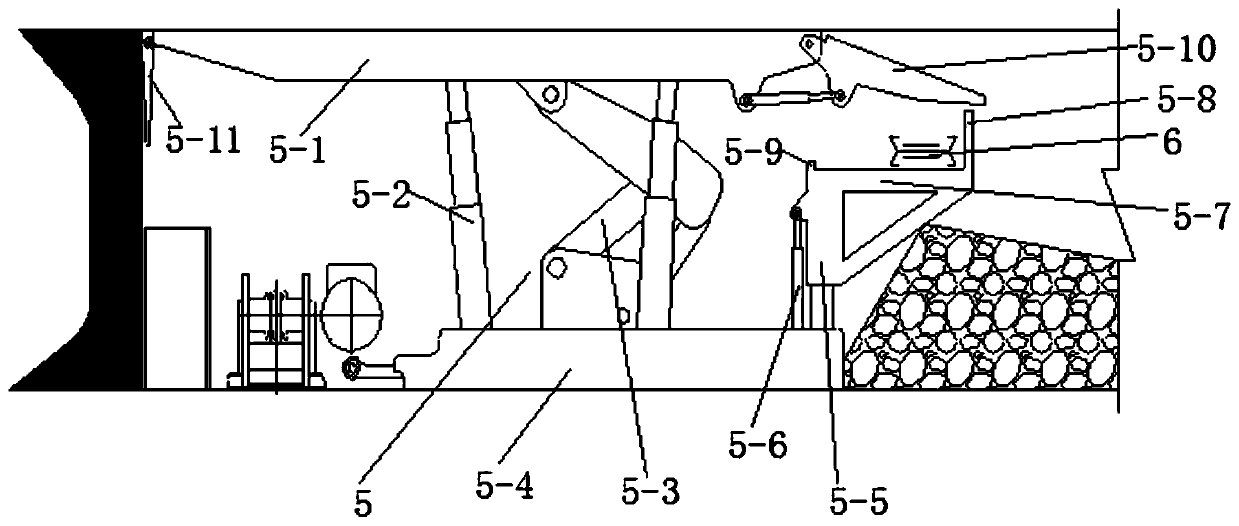

[0035] The invention provides a coal mine goaf dry filling system, such as figure 1 As shown, it includes a storage bin 1 and a shaft 3 arranged on the ground, and the discharge port of the storage bin 1 passes through a tubular belt conveyor 4 arranged in the shaft 3 and a conveyor belt arranged at the end of the coal mining face 9. The machine 8 is connected; the coal mining face 9 is arranged with a filling support 5, and a scraper conveyor 6 is arranged on the filling support 5, and the scraper conveyor 6 is arranged on the working platform 5-7 on the base of the filling support, and the scraper conveys The machine 6 is overlapped with the reloading machine 8, and the scraper groove of the scraper conveyor 6 is provided with a discharge port 7; it also includes a buffer bin 2 arranged in the well lane 3, the discharge port of the storage ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com