Nanometer stripping composite material and preparation method and application thereof

A kind of composite material and nanotechnology, which is applied in the field of preparation and nano-stripping composite materials, can solve the problems of poor dispersion of layered nano-sheets, and achieve the effects of mass industrialization, environmental pollution, and improved peeling degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

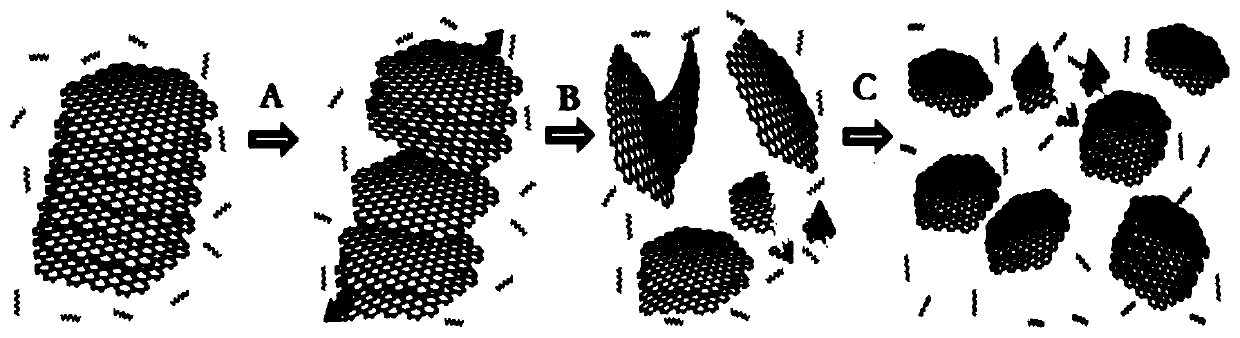

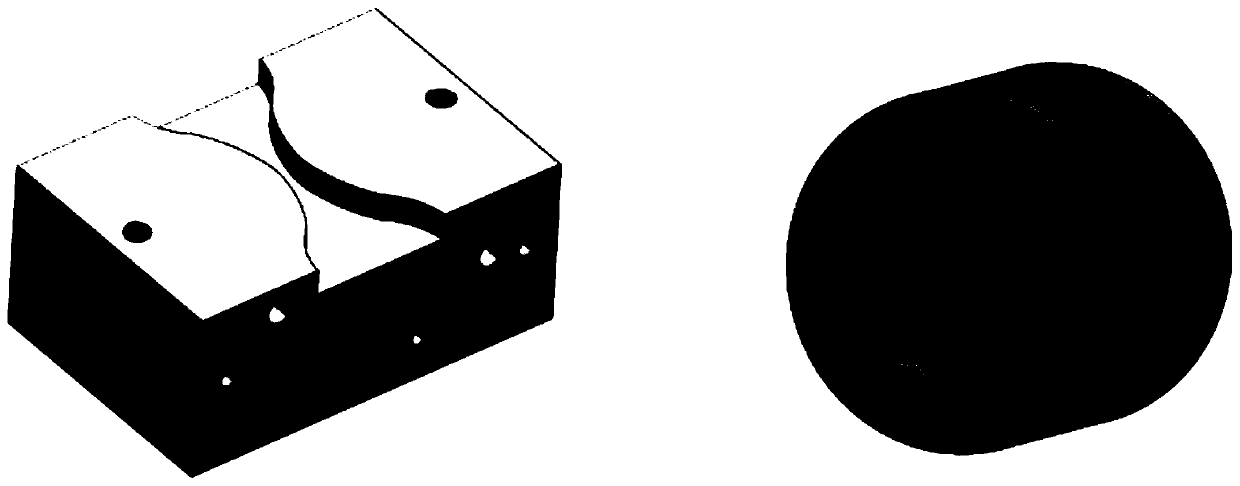

Method used

Image

Examples

Embodiment 1

[0042] (1) Evenly drop 4.7ml of A151 silane coupling agent into 140g of graphene microchips, stir evenly, then mix it with 1860g of polypropylene (PP) and add 20g of lubricant in a high-speed mixer at 70°C Down mixing 5min, obtains reaction mixture;

[0043] (2) The reaction mixture obtained in step (1) is accurately fed into an extruder with a screw diameter of 35mm and a length-to-diameter ratio of 40:1 with a feeding device for high shear and high residence time (shear stress is 0.16MPa~ 0.2MPa, the residence time is 400s ~ 600s), the screw speed is 200rpm, the temperature of each zone is between 160°C ~ 210°C, and finally through the shearing first, then the bidirectional tensile force field and then the chaotic mixing force field Extrude the machine head to complete the peeling of the graphene micro flakes; the obtained sheet is the graphene micro flakes / PP composite material.

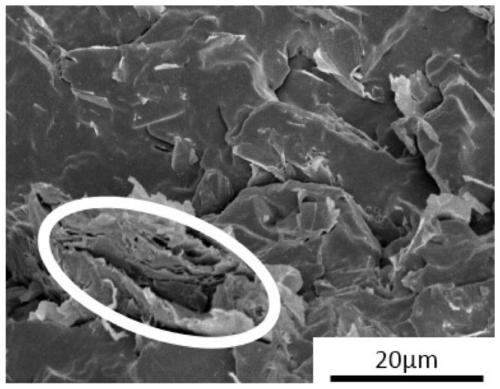

[0044] The scanning electron microscope figure of the graphene microchip / PP composite materia...

Embodiment 2

[0047] (1) Evenly drop 4.7ml of KH560 silane coupling agent into 140g graphene microchips, stir evenly, then mix it with 1860g acrylonitrile-butadiene-styrene copolymer (ABS) and add 20g The lubricant was mixed in a high-speed mixer at 80°C for 10 minutes to obtain a reaction mixture;

[0048] (2) The reaction mixture obtained in step (1) is accurately fed into a twin-screw extruder with a screw diameter of 35 mm and a length-to-diameter ratio of 40:1 with a feeding device for high shear and high residence time (shear stress is 0.16 MPa~0.2MPa, the residence time is 400s~600s) melt blending, the screw speed is 100rpm, the temperature of each zone is between 170℃~220℃, and finally through the shearing first, then the bidirectional tensile force field and then the chaotic mixing force Extrude on the machine head of the field to complete the peeling of the graphene micro-sheets; the obtained sheet is the graphene micro-sheet / ABS composite material.

[0049] Adopt the test method...

Embodiment 3

[0051] (1) Evenly drop 4.7ml of titanate coupling agent into 140g of graphene microchips, stir evenly, then mix it with 1860g of polypropylene (PP), add 20g of lubricant and mix in a high-speed mixer at 70°C 10min, obtain reaction mixture;

[0052] (2) The reaction mixture obtained in step (1) is accurately sent into a twin-screw extruder with a screw diameter of 35mm and a length-diameter ratio of 40:1 with a feeding device for high shear and high residence time (shear stress is 0.14MPa~0.16MPa, the residence time is 250s~450s), the screw speed is 300rpm, the temperature of each zone is between 150℃~200℃, and finally extruded by the head with the first shear and then the bidirectional tensile force field. Complete the stripping of the graphene microflakes; the obtained sheet is the graphene microflake / PP composite material.

[0053] Adopt the test method that embodiment 1 provides to test the graphene microchip / PP composite material that embodiment 3 obtains, the result show...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com