A kind of synthetic method of the stilbene biphenyl fluorescent whitening agent of slight blue tone

A technology of stilbene biphenyls and fluorescent whitening agents, which is applied in the field of fluorescent whitening agents to achieve the effects of improving purity, reducing potential safety hazards and high product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] In a dry 500ml four-necked flask, sequentially add 130g of dimethylformamide, 34g of 4,4'-bis(diethoxyphosphonomethyl)biphenyl and 31.96g of sodium benzaldehyde o-sulfonate; then start stirring Keep warm at room temperature for 0.5h; under stirring at 30°C, add 9.2g of solid potassium hydroxide in 4 times on average for a total of 2 hours; after the addition, raise the temperature to 50°C and keep warm for 8h; The solvent was distilled off at ℃; after the distillation, 136g of 3% sodium chloride aqueous solution was added, cooled to 5°C, filtered, and dried at 100°C to obtain the target product 4,4-bis(2-disulfonate sodium styryl- ) biphenyl 42.08g. The percentage of target product determined by liquid chromatography is: 98.7%.

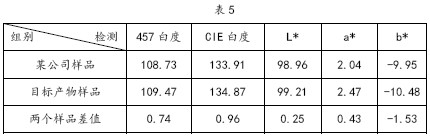

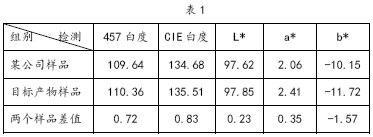

[0024] The whiteness and shade data are identified in Table 1 with an infrared dyeing machine (model DL-6000P) and a desktop expert spectrophotometer (X_Rite CE 7000A):

[0025]

Embodiment 2

[0027] In a dry 500ml four-necked flask, sequentially add 130g of dimethylformamide, 34g of 4,4'-bis(diethoxyphosphonomethyl)biphenyl and 31.96g of sodium benzaldehyde o-sulfonate; then start stirring Insulate at room temperature for 0.5h; stir at 15°C, add 9.2g of solid potassium hydroxide in 4 times on average, and the total addition time is 2 hours; Evaporate the solvent; after the distillation, add 136g of 3% sodium chloride aqueous solution, cool to 5°C, filter, and dry at 100°C to obtain the target product 4,4-bis(2-disulfonate sodium styryl-) Benzene 42.01g. The percentage of target product determined by liquid chromatography is: 98.8%.

[0028] The whiteness and shade data are identified in Table 2 with an infrared dyeing machine (model DL-6000P) and a desktop expert spectrophotometer (X_Rite CE 7000A):

[0029]

Embodiment 3

[0031] In a dry 500ml four-necked flask, sequentially add 130g of dimethylformamide, 34g of 4,4'-bis(diethoxyphosphonomethyl)biphenyl and 31.96g of sodium benzaldehyde o-sulfonate; then start stirring Incubate at room temperature for 0.5h; under stirring at 50°C, add 9.2g of solid potassium hydroxide in 4 times on average, and the addition time is 2 hours in total; after the addition, continue to keep warm for 8h; after the reaction is over, evaporate the solvent at 150-160°C After the distillation, add 136g concentration of 3% sodium chloride aqueous solution, filter after cooling to 5°C, and dry to obtain the target product 4,4-bis(2-disulfonate sodium styryl-)biphenyl 42.12g. The percentage of target product determined by liquid chromatography is: 98.5%.

[0032] The whiteness and shade data are identified in Table 3 with an infrared dyeing machine (model DL-6000P) and a desktop expert spectrophotometer (X_Rite CE 7000A):

[0033]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com