A carrier fluidized mbbr moving bed biofilm reactor and its technology

A moving bed biofilm and reactor technology, which is applied to the carrier fluidized MBBR moving bed biofilm reactor and process field, can solve the problems of the biofilm reactor covering a large area, unsatisfactory treatment effect, and inability to adjust and use. , to achieve the effect of improving sewage treatment effect, good water conduction effect and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

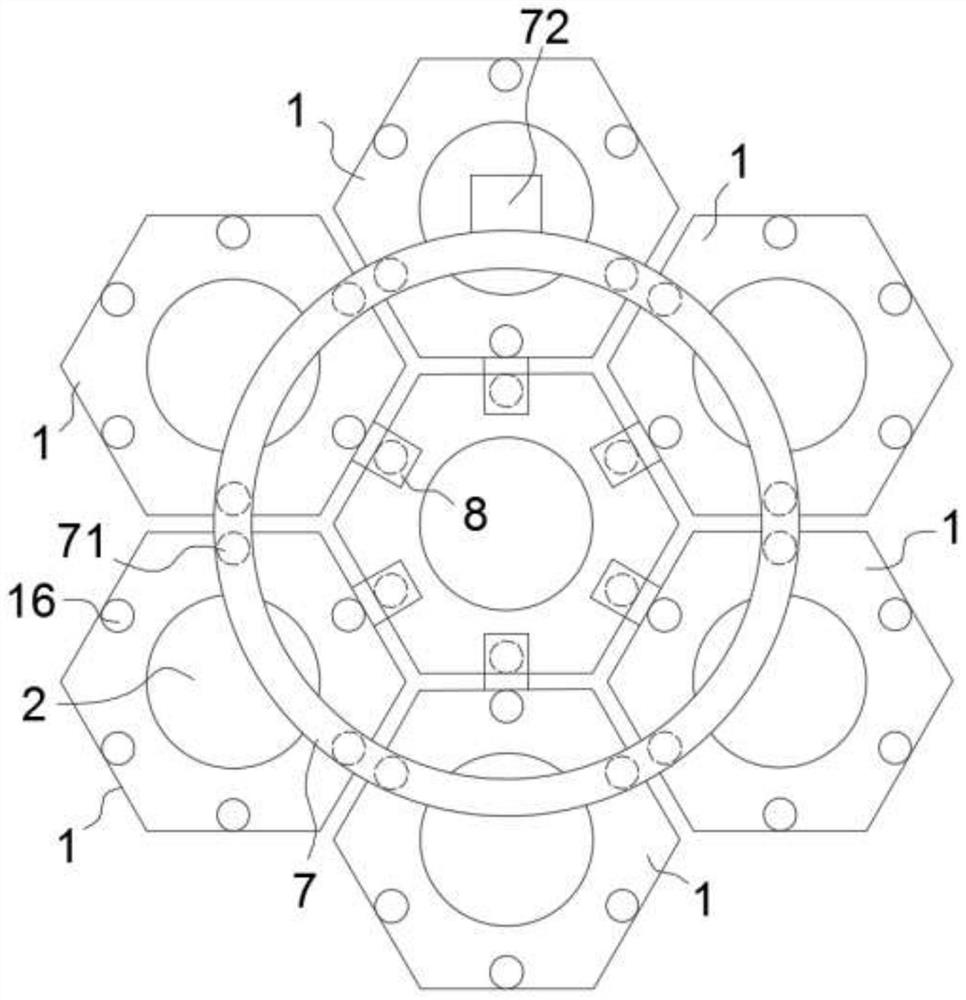

[0045] A carrier fluidized MBBR moving bed biofilm reactor, such as figure 1 As shown, it mainly includes a plurality of reactors 1 and an annular water injection pipe 7. The plurality of reactors 1 are divided into a central reactor 1 and an outer reactor 1. There are 6 outer reactors 1 surrounding the center. On the outside of the 16 edges of the reactor, each outer reactor 1 is connected to the reactor 1 at the center through a joint 8, and the annular water injection pipe 7 is arranged above the reactor 1, and is connected to each outer reactor 1 through a water injection connecting pipe 71. The reactor 1 is connected, and the annular water injection pipe 7 is provided with a water injection main port 72;

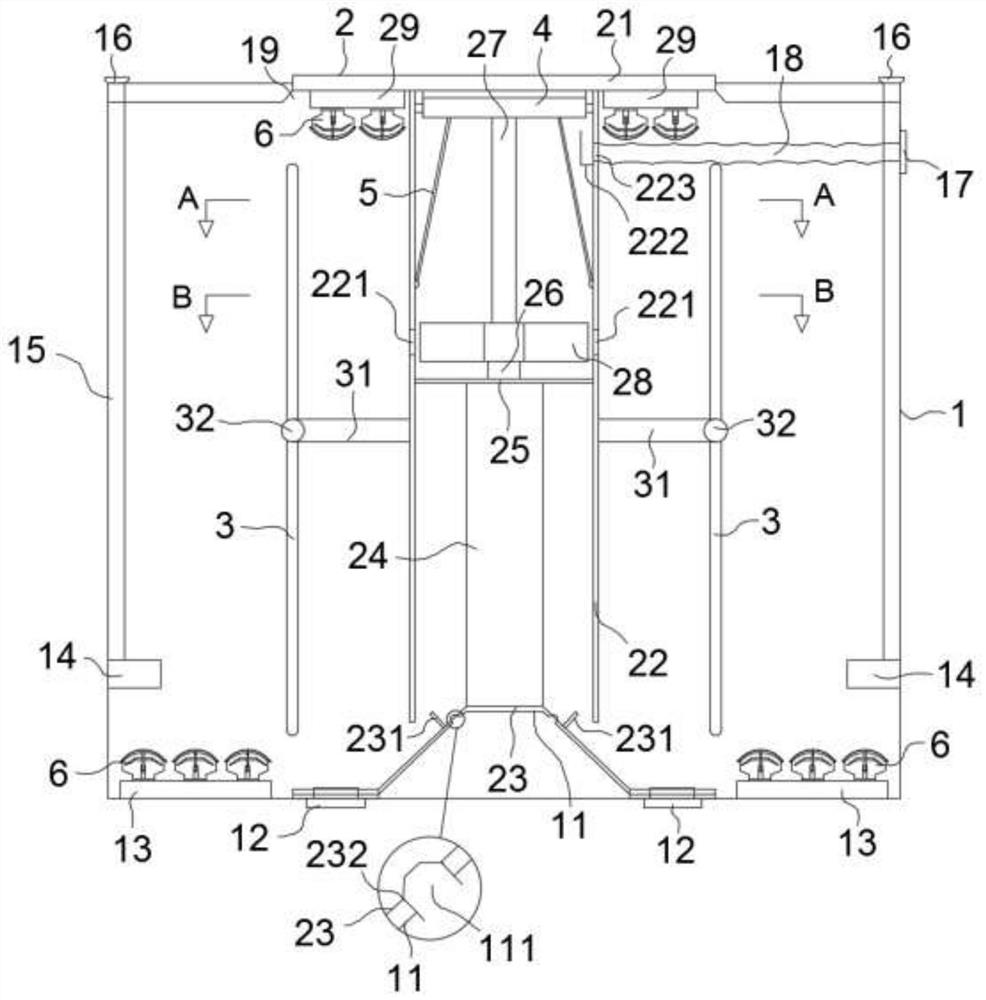

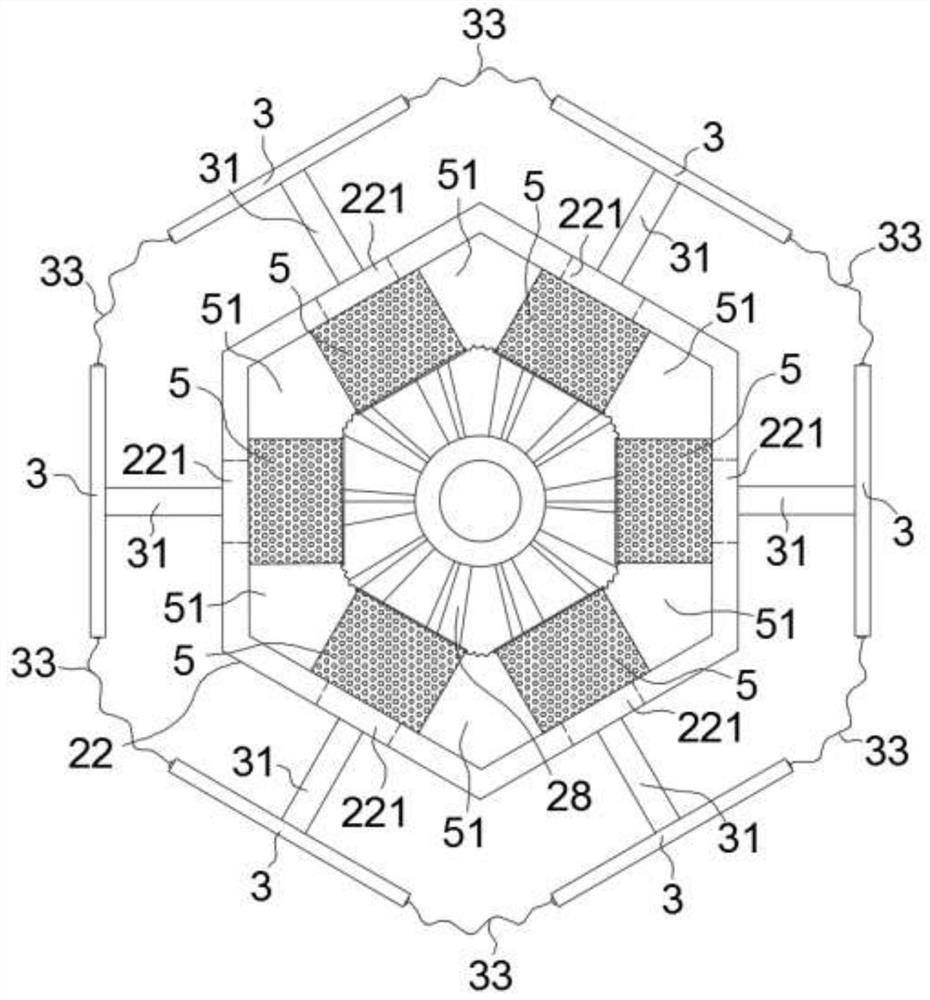

[0046] like figure 2 As shown, the reactor 1 is in the shape of a hexagonal prism, and the center of its upper top surface is provided with an insertion hole 19, and each edge of the upper surface of the reactor 1 is respectively provided with a water injection port 1...

Embodiment 2

[0062] Embodiment 2 is basically the same as Embodiment 1, the difference is that, as Figure 12 As shown, the MBBR moving bed biofilm reactor mainly includes three reactors 1, and the three reactors 1 are sequentially connected in series through joints 8.

[0063] At the same time, other different assembly methods can also be carried out according to terrain needs and the like.

experiment example 1

[0068] Experimental Example 1: After being treated by the device and process of Experimental Example 1, the chromaticity of the effluent is 19 times, COD 110mg / L, SS<70mg / L; at the same time, there is no clogging during the whole process of the device, and the total treatment efficiency is compared with that of the opposite Ratio increased by 29%;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com