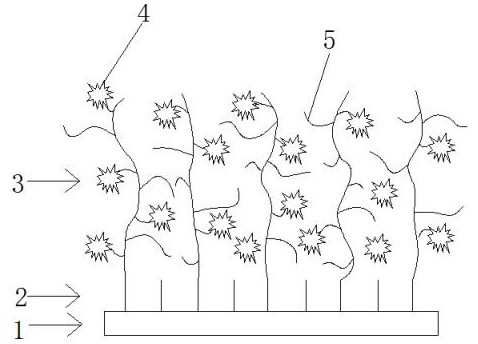

Preparation method and application of a three-dimensional chip for screening components of traditional Chinese medicine

A technology of traditional Chinese medicine components and three-dimensional chips, which is applied to chemical instruments and methods, analytical materials, and laboratory containers, etc., can solve the problems of poor specificity of small molecule array chips and low immobilization capacity of small drug molecules, and achieve improved Fixed amount, guaranteed uniformity, and solved the effect of poor specificity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

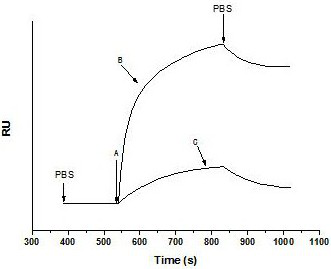

Examples

Embodiment 1

[0033] (1) Add deionized water, 25% ammonia water and 30% hydrogen peroxide into the chip cleaner, wherein the volume ratio of deionized water, ammonia water and hydrogen peroxide is 5:1:1, and then put it on the surface For glass substrates coated with gold film, heat up to 50°C to clean the substrate for 30 minutes, then rinse with deionized water and ethanol, and dry with nitrogen gas to complete the cleaning;

[0034] (2) Soak the cleaned substrate obtained in step (1) in 1mM 2-mercaptoethylamine ethanol solution, place it at room temperature for 15 hours, self-assemble a monomolecular layer on the surface of the substrate, and then assemble the surface with 2 - The substrate of the mercaptoethylamine monolayer is soaked in the N,N-dimethylformamide (DMF) solution containing triethylamine and 2-bromopropionyl bromide, reacted at -5°C for 3 hours, and then React at room temperature for 8 hours, then clean the chip to obtain a substrate with an initiator attached to the surf...

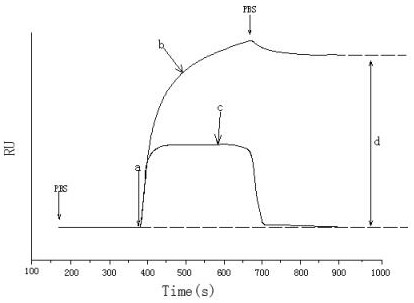

Embodiment 2

[0037] (1) Add deionized water, 25% ammonia water and 30% hydrogen peroxide into the chip cleaner, wherein the volume ratio of deionized water, ammonia water and hydrogen peroxide is 5:1:1, and then put it on the surface For the glass substrate coated with gold film, heat up to 70°C to clean the substrate for 10 minutes, then rinse with deionized water and ethanol, and blow dry with nitrogen to complete the cleaning;

[0038] (2) Soak the cleaned substrate obtained in step (1) in 5mM 2-mercaptoethylamine ethanol solution, place it at room temperature for 10 hours, self-assemble a monomolecular layer on the surface of the substrate, and then assemble the surface with 2 - The substrate of the mercaptoethylamine monolayer is soaked in the N,N-dimethylformamide (DMF) solution containing triethylamine and 2-bromopropionyl bromide, reacted at 5°C for 2 hours, and then at room temperature The reaction was carried out for 5 hours, and then the chip was cleaned to obtain a substrate wi...

Embodiment 3

[0041](1) Add deionized water, 25% ammonia water and 30% hydrogen peroxide into the chip cleaner, wherein the volume ratio of deionized water, ammonia water and hydrogen peroxide is 5:1:1, and then put it on the surface For glass substrates coated with gold film, heat up to 60°C to clean the substrate for 20 minutes, then rinse with deionized water and ethanol, and blow dry with nitrogen to complete the cleaning;

[0042] (2) Soak the cleaned substrate obtained in step (1) in 2mM 2-mercaptoethylamine ethanol solution, place it at room temperature for 12 hours, self-assemble a monomolecular layer on the surface of the substrate, and then assemble the surface with 2 - The substrate of the mercaptoethylamine monolayer is soaked in the N,N-dimethylformamide (DMF) solution containing triethylamine and 2-bromopropionyl bromide, and reacted at 0°C for 2.5 hours, then at room temperature The reaction was carried out for 6 hours, and then the chip was cleaned to obtain a substrate with...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com