A preparation method of high hydrostatic strength polytetrafluoroethylene hollow fiber membrane

A polytetrafluoroethylene, hydrostatic strength technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc. Simple, hydrostatically strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with specific examples.

[0023] In order to overcome all or part of the deficiencies in the prior art, an embodiment of the present invention provides a method for preparing a polytetrafluoroethylene hollow fiber membrane with high hydrostatic strength. The preparation method includes the following steps:

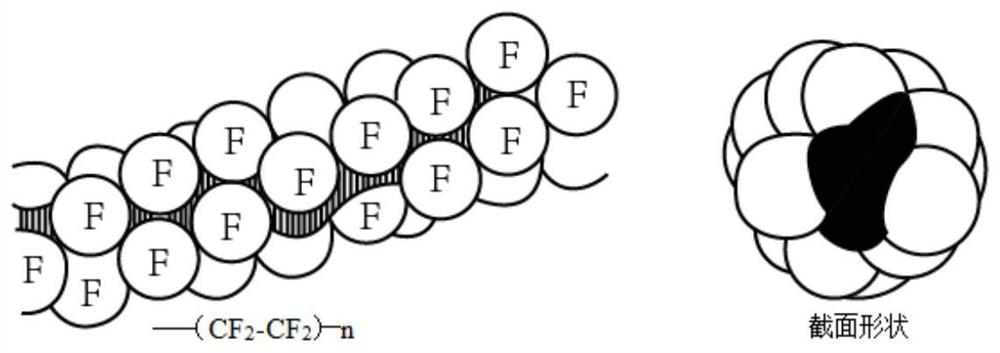

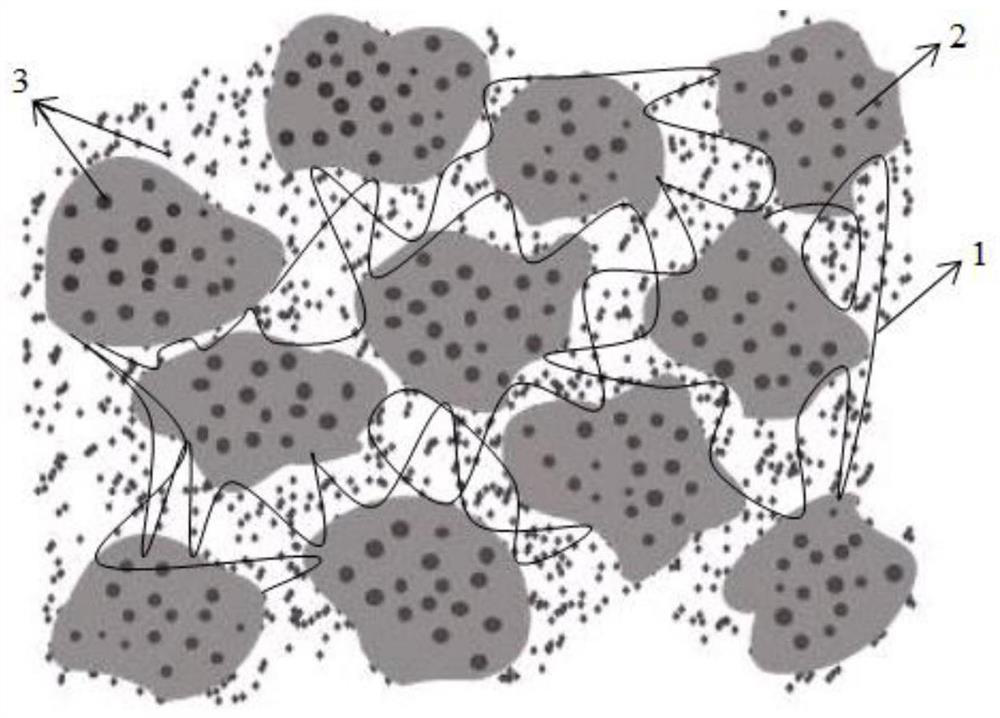

[0024] (1) Mixing and aging: Mix PTFE (polytetrafluoroethylene) resin powder, liquid lubricating oil, and PTFE ultra-fine short fibers evenly, and let the resin powder and liquid The lubricant is fully mixed to form a PTFE material;

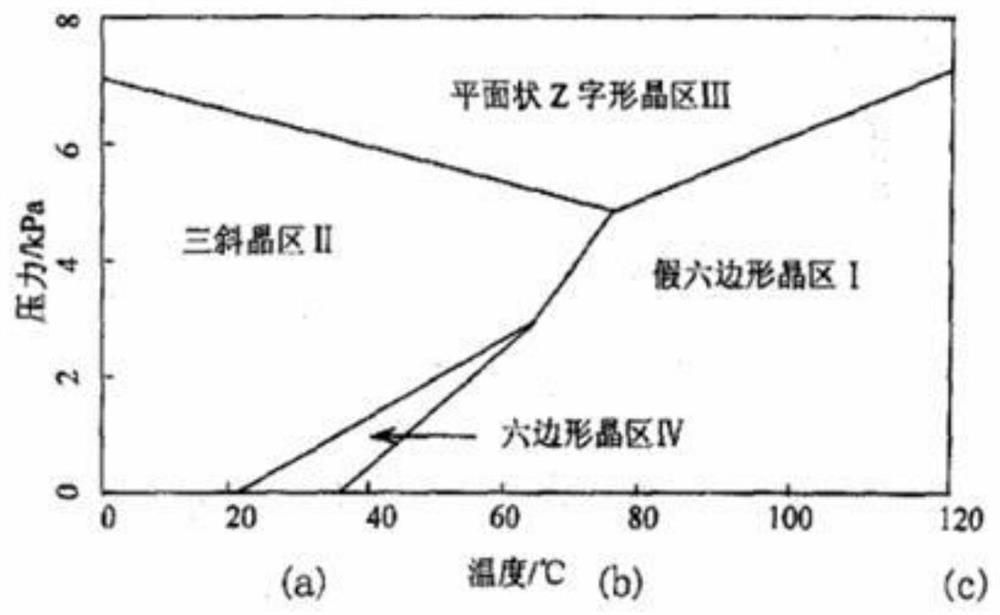

[0025] (2) Paste extrusion: The PTFE material is pressed into a tubular blank on a compactor at 30-50°C, and the tubular blank is extruded at a temperature of 40-60°C through a pusher to form PTFE pipe;

[0026] (3) Degreasing and axial stretching: Dry the PTFE...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com