ZnO superfine nano-particles, ZnO slurry, preparation method and application

A technology of ultra-fine nanoparticles and particles, which is applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., and can solve the problems of prolonging battery energy repayment time, photoanode polycrystalline boundary, unfavorable electron transport, etc. , to achieve the effect of eliminating surface impurity defects, improving semiconductor characteristics, and cheap and easy-to-obtain raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

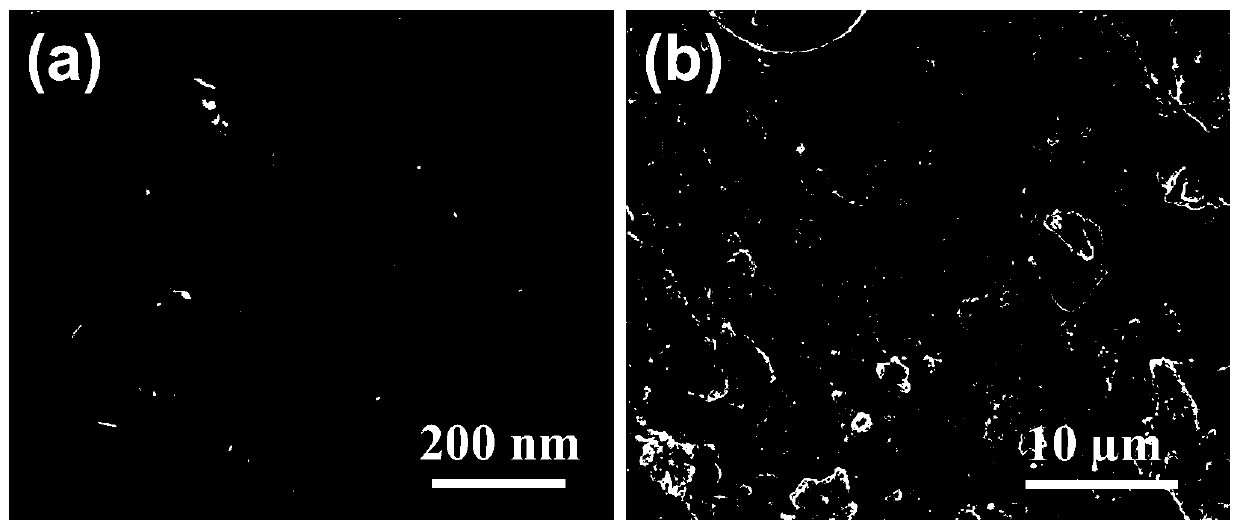

Embodiment 1

[0043] Weigh 10g of sodium hydroxide and 20g of zinc nitrate hexahydrate, add them to an agate mortar and mix, grind for 20min to obtain a white paste; transfer the paste to a 50ml centrifuge tube, add 40ml of deionized water, shake After uniformity, let it stand for 3 hours; then add 10ml of deionized water and mix well, then age at room temperature (25°C) for 20 hours; add 40ml of deionized water to the aged sample, and wash the precipitate under the condition of ultrasonic vibration and vortex vibration, The frequency of ultrasonic oscillation is 35kHz, and the time is 5min. The frequency of vortex oscillation is 20Hz, and the time is 5min; then the precipitate is centrifuged at 3000rpm, and the time is 5min; the obtained white precipitate is ZnO ultrafine nanoparticles.

[0044] Add the obtained white precipitate to 20ml of deionized water, mix and disperse under the condition of ultrasonic vibration and vortex vibration, repeat the dispersion 4 times in total, the frequenc...

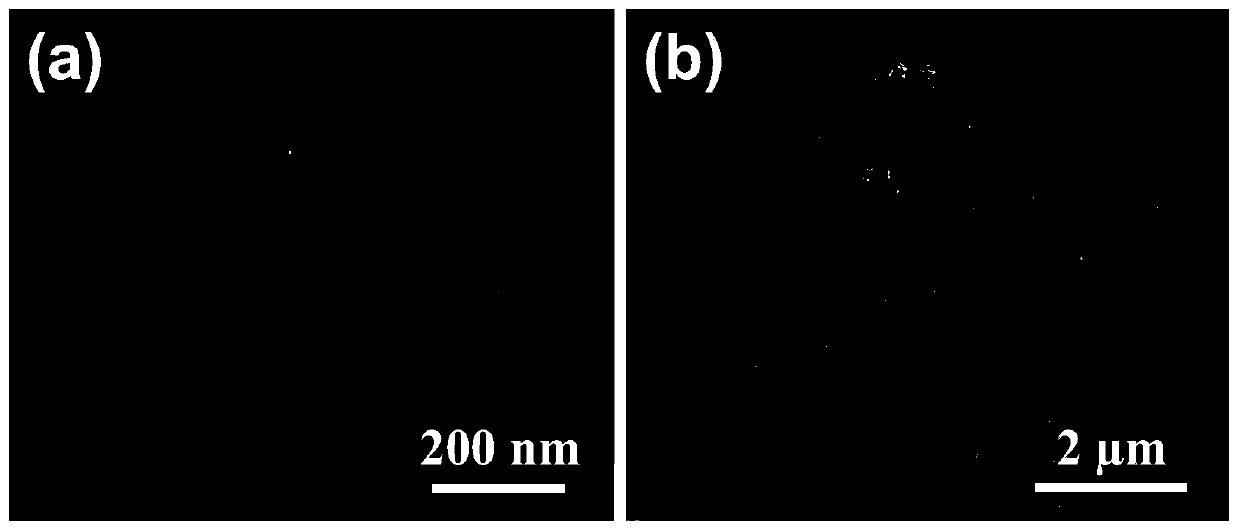

Embodiment 2

[0047] Weigh 10g of sodium hydroxide and 20g of zinc nitrate hexahydrate, add them to an agate mortar and mix, grind for 20min to obtain a white paste; transfer the paste to a 50ml centrifuge tube, add 40ml of deionized water, shake Let stand for 3 hours after uniformity; then add 10ml of deionized water and mix well, then age at 50°C for 20 hours; add 40ml of deionized water to the aged sample, wash the precipitate under the conditions of ultrasonic vibration and vortex vibration, and ultrasonic vibration The frequency is 35kHz, the time is 5min, the frequency of vortex oscillation is 20Hz, and the time is 5min; then the precipitate is centrifuged at 3000rpm, and the time is 5min; the obtained white precipitate is ZnO ultrafine nanoparticles.

[0048] Add the obtained white precipitate to 20ml of deionized water, mix and disperse under the condition of ultrasonic vibration and vortex vibration, repeat the dispersion 4 times in total, the frequency of each ultrasonic vibration ...

Embodiment 3

[0052] Weigh 10g of sodium hydroxide and 20g of zinc nitrate hexahydrate, add them to an agate mortar and mix, grind for 20min to obtain a white paste; transfer the paste to a 50ml centrifuge tube, add 40ml of deionized water, shake Let stand for 3 hours after uniformity; then add 10ml of deionized water and mix well, then age at 90°C for 20 hours; add 40ml of deionized water to the aged sample, wash the precipitate under the conditions of ultrasonic vibration and vortex vibration, and ultrasonic vibration The frequency is 35kHz, the time is 5min, the frequency of vortex oscillation is 20Hz, and the time is 5min; then the precipitate is centrifuged at 3000rpm, and the time is 5min; the obtained white precipitate is ZnO ultrafine nanoparticles.

[0053] Add the obtained white precipitate to 20ml of deionized water, mix and disperse under the condition of ultrasonic vibration and vortex vibration, repeat the dispersion 4 times in total, the frequency of each ultrasonic vibration ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com