Coke oven automatic release ignition control device and control method

An ignition control and automatic technology, applied in furnace safety devices, coke ovens, general control systems, etc., can solve problems such as low degree of automation, air pollution, and abnormal pressure fluctuations in the gas collecting pipe, and avoid frequent fluctuations and accidents. , reduce the effect of repeated adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

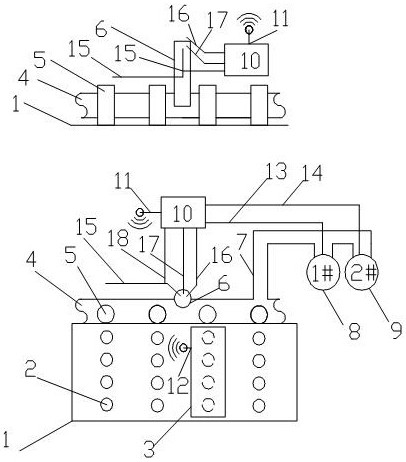

[0013] Example: see image 3 , a coke oven automatic release ignition control device, mainly by the controller 10, wireless communication devices 11 and 12, 1# induced draft fan state detection signal 13, 2# induced draft fan state detection signal 14, gas pipeline 15, gas detection device 16 , a redundant ignition device 17 and a gas pipeline electric control valve 18, etc., the wireless communication device 11 on the release ignition side is installed on the controller 10, and the wireless communication device 12 on the coaling car side is installed on the coaling car 3, The coal loading car transmits the furnace number information and coal feeding status information to the controller 10 through the wireless communication device, and the 1# induced draft fan status detection signal 13 and the 2# induced draft fan status detection signal 14 represent the 1# induced draft fan and 2# induced draft fan respectively The operating status of the system is sent to the controller 10 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com