Epoxy olefin and olefin ether modified polymerized rosin resin

A technology of epoxy-based olefin and polymerized rosin, which is applied in chemical modification of natural resins, adhesive additives, polymer adhesive additives, etc., can solve problems such as increased hardness, decreased initial viscosity, and decreased flexibility, and achieves enhanced Adhesive properties, improved adhesive properties, and enhanced flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

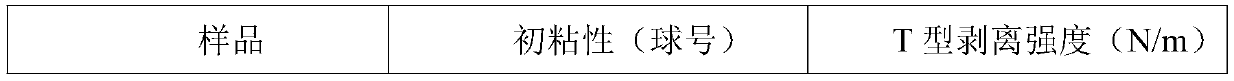

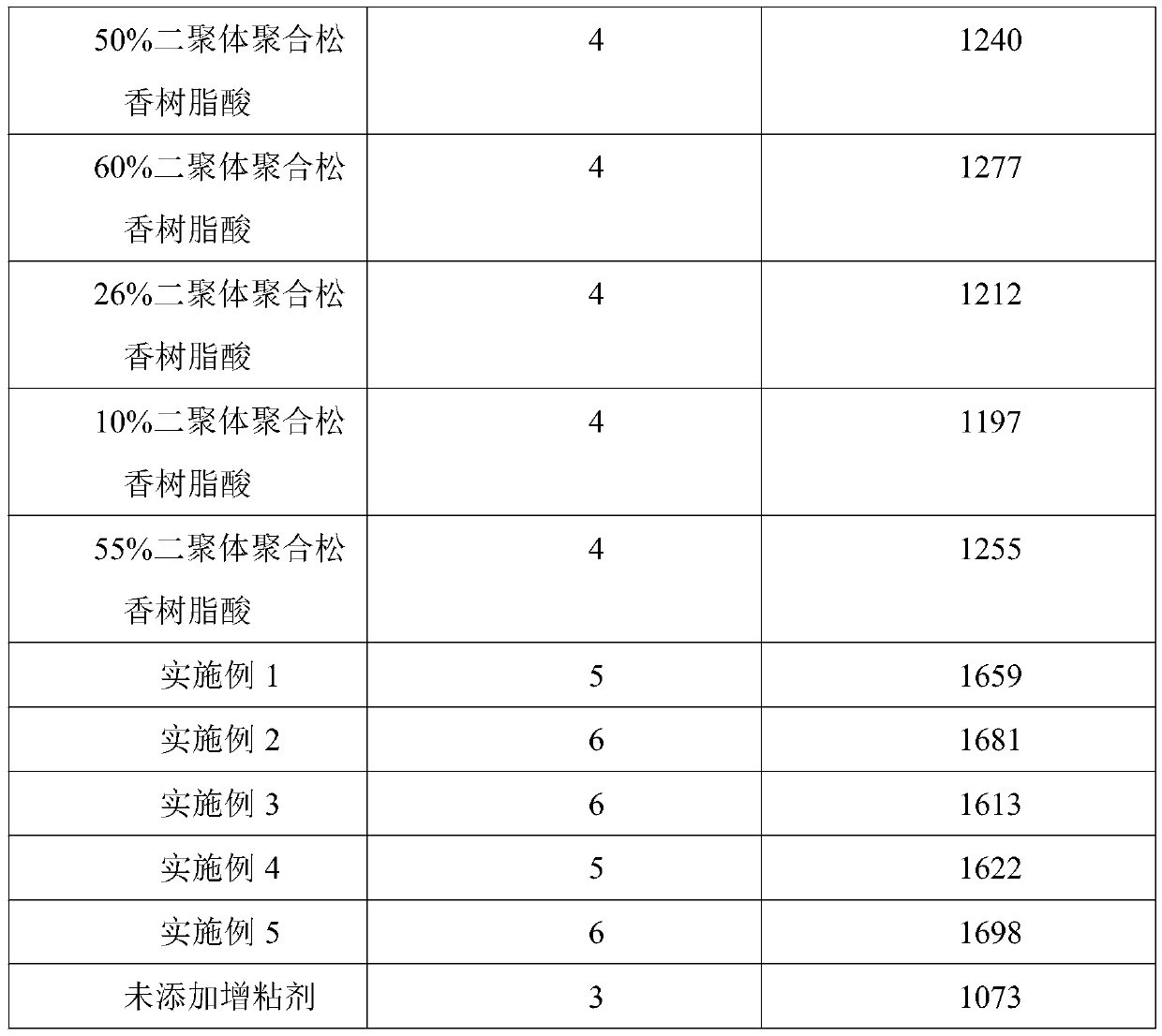

Embodiment 1

[0020] A preparation method for epoxy olefin and olefin ether modified polymerized rosin resin, characterized in that it comprises the following steps:

[0021] S1. In parts by weight, add 100 parts of polymerized rosin resin acid into the solvent, heat up to 150°C, add 2.5 parts of organic alkali ammonium catalyst after the polymerized rosin resin acid melts, and then dropwise add epoxy olefin and olefin ether raw materials , the dropping time is 0.5h, the temperature is raised to 130°C, and the heating is stopped when the acid value of the polymerized rosin resin is 6mg KOH / g;

[0022] S2. Continue to add the solvent, then neutralize the organic base catalyst with an acid agent, and obtain the substrate after washing with water. The substrate is distilled under reduced pressure at 140° C. and then dried to obtain epoxy olefin and olefin ether modified polymerized rosin trees.

[0023] The dimer content in the polymerized rosin resin acid is 50%.

[0024] Described solvent i...

Embodiment 2

[0030] A preparation method for epoxy olefin and olefin ether modified polymerized rosin resin, characterized in that it comprises the following steps:

[0031] S1. In parts by weight, add 100 parts of polymerized rosin resin acid to the solvent, heat up to 110°C, add 0.22 parts of organic alkali ammonium catalyst after the polymerized rosin resin acid melts, and then dropwise add epoxy olefin and olefin ether raw materials , the dropping time is 0.8h, the temperature is raised to 180°C, and the heating is stopped when the acid value of the polymerized rosin resin is 3mg KOH / g;

[0032] S2. Continue to add the solvent, then neutralize the organic base catalyst with an acid agent, and obtain the substrate after washing with water. The substrate is distilled under reduced pressure at 180° C. and then dried to obtain epoxy olefin and olefin ether modified polymerized rosin trees.

[0033] The dimer content in the polymerized rosin resin acid is 60%.

[0034] The solvent is methy...

Embodiment 3

[0040] A preparation method for epoxy olefin and olefin ether modified polymerized rosin resin, characterized in that it comprises the following steps:

[0041] S1. In parts by weight, add 100 parts of polymerized rosin resin acid to the solvent, heat up to 50°C, add 0.2 parts of organic alkali ammonium catalyst after the polymerized rosin resin acid melts, and then dropwise add epoxy olefin and olefin ether raw materials , the dropping time is 1h, the temperature is raised to 50° C., and the heating is stopped when the acid value of the polymerized rosin resin is 1.3 mg KOH / g;

[0042] S2. Continue to add the solvent, then neutralize the organic base catalyst with an acid agent, and obtain the substrate after washing with water. The substrate is distilled under reduced pressure at 100° C. and then dried to obtain epoxy olefin and olefin ether modified polymerized rosin trees.

[0043] The dimer content in the polymerized rosin resin acid is 26%.

[0044] The solvent is a mix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com