Polyamic acid solution, transparent polyimide resin film and transparent substrate using same

A technology of polyamic acid and solution, which is applied in the fields of instruments, optics, photovoltaic power generation, etc. It can solve the problems of reduced thermal and mechanical properties, low transmittance in the visible light region, and no significant improvement in transmittance, and achieves high elastic modulus , low yellowness, excellent physical properties and product reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

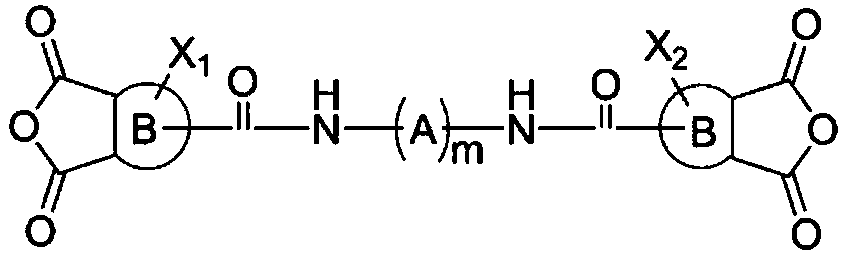

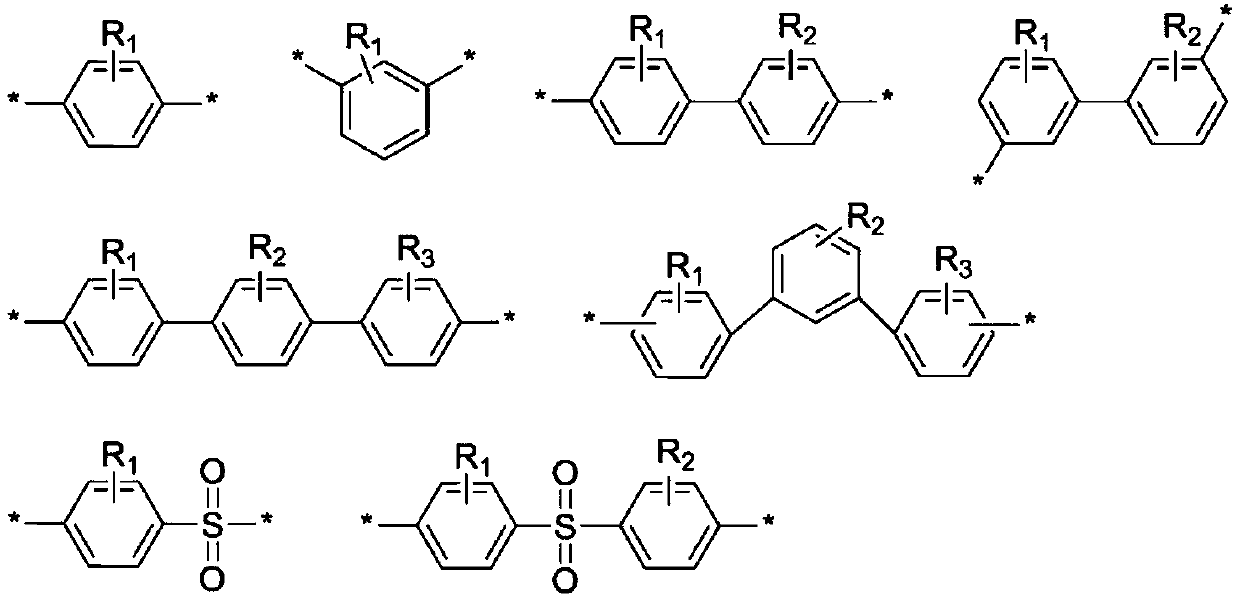

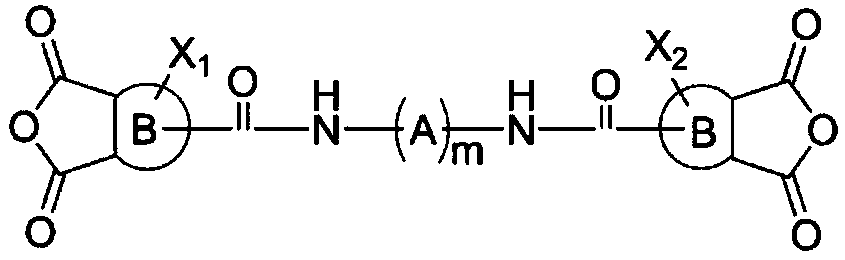

Method used

Image

Examples

Embodiment 1

[0085] [Example 1] Production of transparent polyimide film

[0086] 1-1. Manufacture of polyamic acid solution

[0087] After charging 98.8 g of N,N'-dimethylacetamide (DMAc) into a 100 ml three-necked round bottom flask, the temperature of the flask was raised to 50°C. Thereafter, 10.0 g of 2,2'-TFDB was added to the flask, and 0.8 g of m-PDA was added 30 minutes later. This was stirred for 1 hour to completely dissolve 2,2'-TFDB and m-PDA. Then, 3.6 g of MPTA and 13.8 g of 6FDA were sequentially added to the flask, and the mixture was maintained at 50° C. and dissolved. At this time, the solid content was 20%, and the reaction was then stirred for 3 hours. After completion of the reaction between the monomers, it was left to cool to obtain a polyamic acid solution (solution viscosity at 25° C.: 96 poise (9,600 CPs)).

[0088] 1-2. Production of transparent polyimide film

[0089] After the polyamic acid solution produced in Example 1-1 was spin-coated on glass for ...

Embodiment 2

[0090] [Example 2] Production of transparent polyimide film

[0091] Use p-PDA 0.8g instead of m-PDA, and use PPTA 3.6g instead of MPTA, except that, manufacture polyamic acid solution according to the same method as Example 1-1 (solution viscosity at 25 ℃: 91 poise (9,100 CPs)).

[0092] A transparent polyimide resin film (imidization rate: 85% or more) was produced by the same method as in Example 1-2 using the above polyamic acid solution.

Embodiment 3

[0093] [Example 3] Production of transparent polyimide film

[0094] Use DMAc 98.1g, use 2,2'-TFDB 9.5g, use 4,4'-DDS1.8g instead of m-PDA, use PSHT4.3g instead of MPTA, and use 6FDA 13.2g, in addition, according to the example 1-1 A polyamic acid solution (solution viscosity at 25° C.: 75 poise (7,500 CPs)) was produced in the same manner.

[0095] A transparent polyimide resin film (imidization rate: 85% or more) was produced by the same method as in Example 1-2 using the above polyamic acid solution.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| mechanical strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com