Method for synthesizing monopalmitoyl glyceride

A technology of glyceryl palmitate and a synthesis method, which is applied in the field of fine chemical production, can solve the problems of poor miscibility of glycerol monopalmitate and palm oil, high reaction requirements, influence on the reaction, etc., so as to improve the reaction conversion rate, product The effect of high purity and improved reaction conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

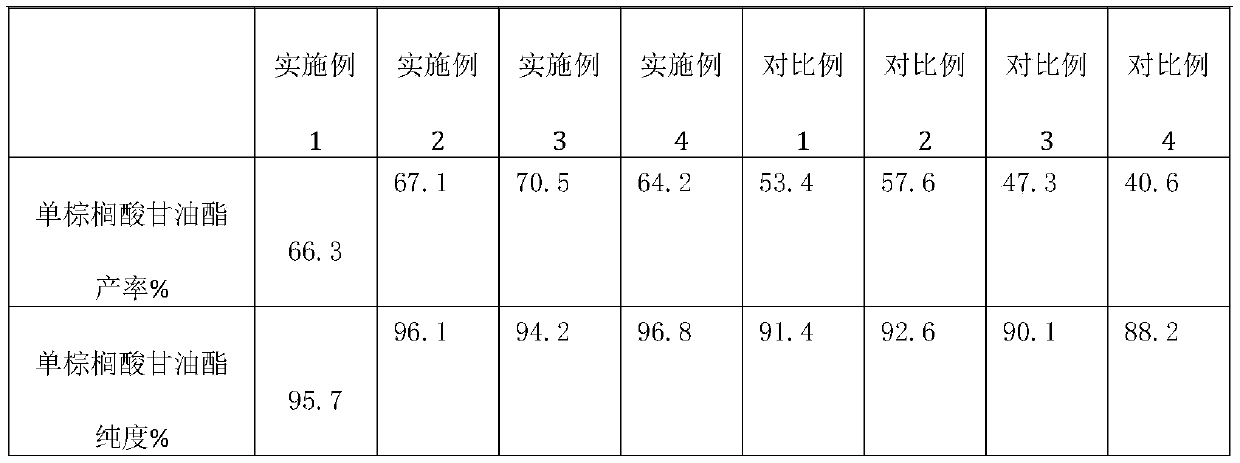

Examples

preparation example Construction

[0023] This case proposes a kind of synthetic method of glycerol monopalmitate, wherein, comprises the following steps:

[0024] 1) Add palm oil and glycerin into the first reactor, stir for 30-60 minutes to fully mix the palm oil and glycerin, and preheat to 100-120°C to obtain the first mixture;

[0025] 2) adding 0.4-0.6% catalyst and 0.2-0.5% phase transfer agent, heating to 200-220° C. and stirring for 3-5 hours to obtain the second mixture;

[0026] 3) adjusting the pH of the second mixture to 5.5-6.5, cooling to 20-30° C., and centrifuging to separate the layers to obtain the crude monopalmitin in the upper layer, and centrifuging to separate the residual glycerol, catalyst, phase transfer agent and by-products in the lower layer;

[0027] 4) distilling the crude monopalmitin to obtain the monopalmitin.

[0028] As yet another embodiment of the present case, wherein, step 1) the mass ratio of palm oil and glycerin is 1:2-4. The raw material ratio of palm oil and glyce...

Embodiment 1

[0040] A kind of synthetic method of glycerol monopalmitate, comprises the following steps:

[0041] 1) Add palm oil and glycerin to the first reactor at a mass ratio of 1:2, and add tert-butanol, stir for 30 minutes to fully mix palm oil and glycerin, the mixing speed is 120r / min; and preheat to 100 °C, to obtain the first mixture;

[0042] 2) Add 0.4% catalyst and 0.2% phase transfer agent, heat to 200°C and stir for 3h, the stirring speed is 120r / min, to obtain the second mixture; wherein the catalyst includes 5 parts by weight of cerium phosphate and 1 part by weight of trioxide Diantimony; the phase transfer agent includes 8 parts by weight of tetrabutylammonium bromide and the cyclodextrin of 2 parts by weight;

[0043] 3) Adjust the pH of the second mixture to 5.5-6.5, cool to 20°C, and centrifuge the layers at a centrifugal speed of 3000r / min for 5 minutes to obtain the crude product of glycerol monopalmitate in the upper layer, and centrifuge to separate the residual...

Embodiment 2

[0046] A kind of synthetic method of glycerol monopalmitate, comprises the following steps:

[0047]1) Add palm oil and glycerin to the first reactor, the mass ratio of palm oil and glycerin is 1:3, and add tert-butanol, stir for 50min to fully mix palm oil and glycerin, the stirring speed is 200r / min, and preheated to 110°C to obtain the first mixture;

[0048] 2) Add 0.5% catalyst and 0.3% phase transfer agent, heat to 200° C. and stir for 4 hours at a stirring speed of 200 r / min to obtain a second mixture; the catalyst includes 6 parts by weight of cerium phosphate and 2 parts by weight of dioxygen trioxide Antimony; Phase transfer agent comprises the tetrabutylammonium bromide of 9 parts by weight and the cyclodextrin of 3 parts by weight;

[0049] 3) Adjust the pH of the second mixture to 5.5-6.5, cool to 20-30°C, and centrifuge to separate the layers at a centrifugal speed of 4000-5000r / min for 7 minutes to obtain the crude product of glyceryl monopalmitate in the upper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com