Sintering-preventing long-service-life double-layer gradient structure thermal barrier coating and preparation method thereof

A technology of thermal barrier coating and gradient structure, which is applied in the direction of coating, metal material coating process, and device for coating liquid on the surface, etc. It can solve the problem of TBC heat insulation function decline, affecting the service life of the coating, and heat insulation pores Disappearance and other problems, to overcome the sharp decline in thermal insulation performance, quickly realize engineering applications, and reduce the driving force of cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

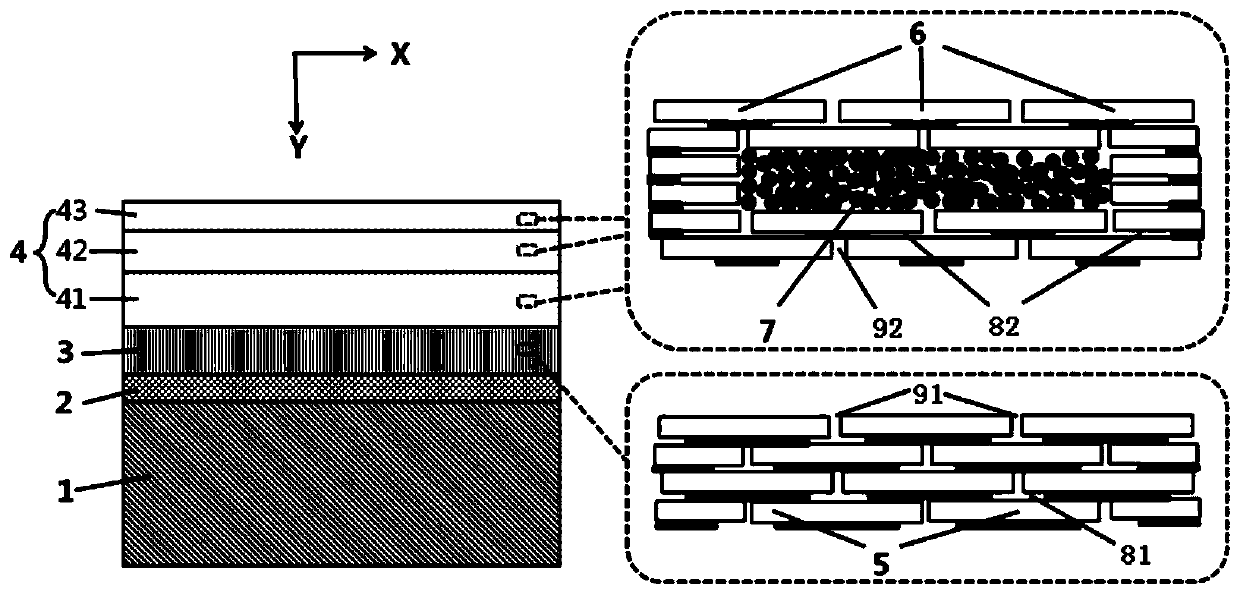

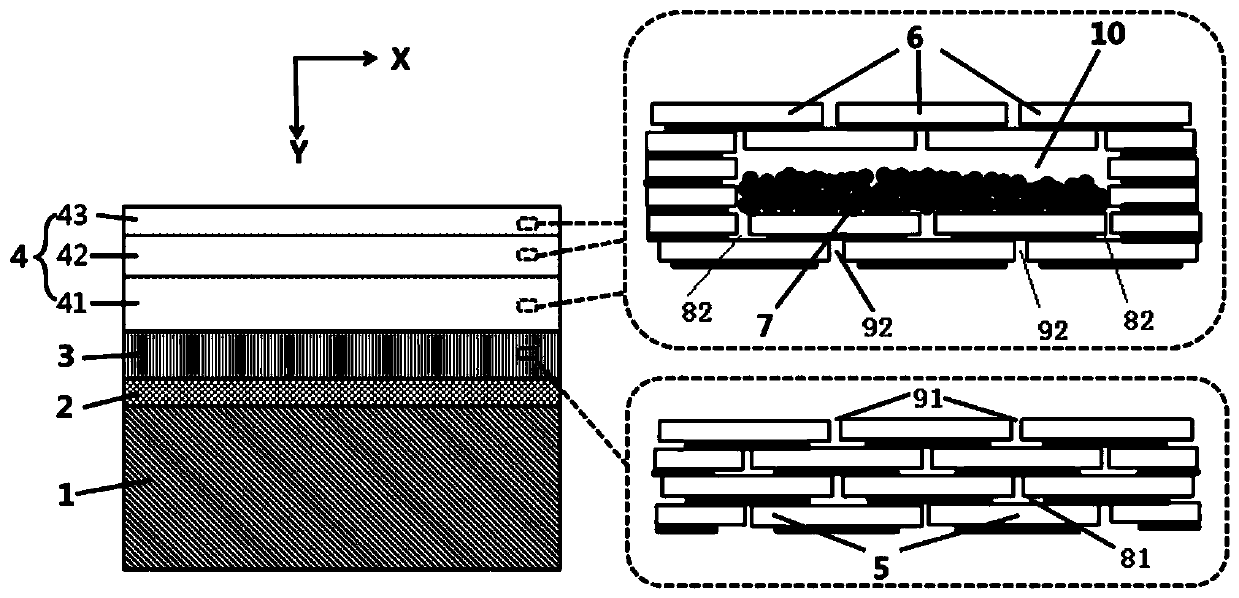

[0045] see figure 1 As shown, the preparation process of the present invention is described by taking the heat insulation layer 4 as an example with three sublayers.

[0046] A method for preparing an anti-sintering long-life double-layer gradient thermal barrier coating, comprising the following steps:

[0047] Step 1. Prepare a metal bonding layer 2 with a thickness of 150 μm on the surface of the cylindrical superalloy substrate 1 by using a low-pressure plasma spraying process. The material of the metal bonding layer 2 is spherical NiCoCrAlTaY powder with a particle size of 10 μm-40 μm.

[0048] Step 2. On the metal bonding layer 2, 8YSZ smelting and crushing powder with a particle size of 5 μm to 25 μm is used to prepare a toughening layer 3 with a thickness of 150 μm by atmospheric plasma spraying. In the process of spraying, in order to make the interlayer bonding rate of the first sheet unit 5 not lower than 50%, use a heating platform to preheat the substrate to 400...

Embodiment 2

[0066] The difference between this embodiment and embodiment 1 is that in step 1, the thermal spraying method used is vacuum plasma spraying, supersonic flame spraying or cold spraying.

Embodiment 3

[0068] The difference between this example and Example 1 is that in step 1, the thickness of the metal bonding layer 2 is 100 μm; in step 2, the temperature of the substrate is preheated to 300° C. during the deposition process; in steps 3 to 5, During the deposition process, the temperature of the substrate is controlled to not exceed 180°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com