Stretchable friction nanogenerator in single electrode mode and preparation method thereof

A nanogenerator and single-electrode technology, which is applied in the field of sensors, can solve the problems of non-stretchability, unstable electrode materials, and unsatisfactory conditions, and achieve the effect of low equipment requirements, low cost, and good tensile properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

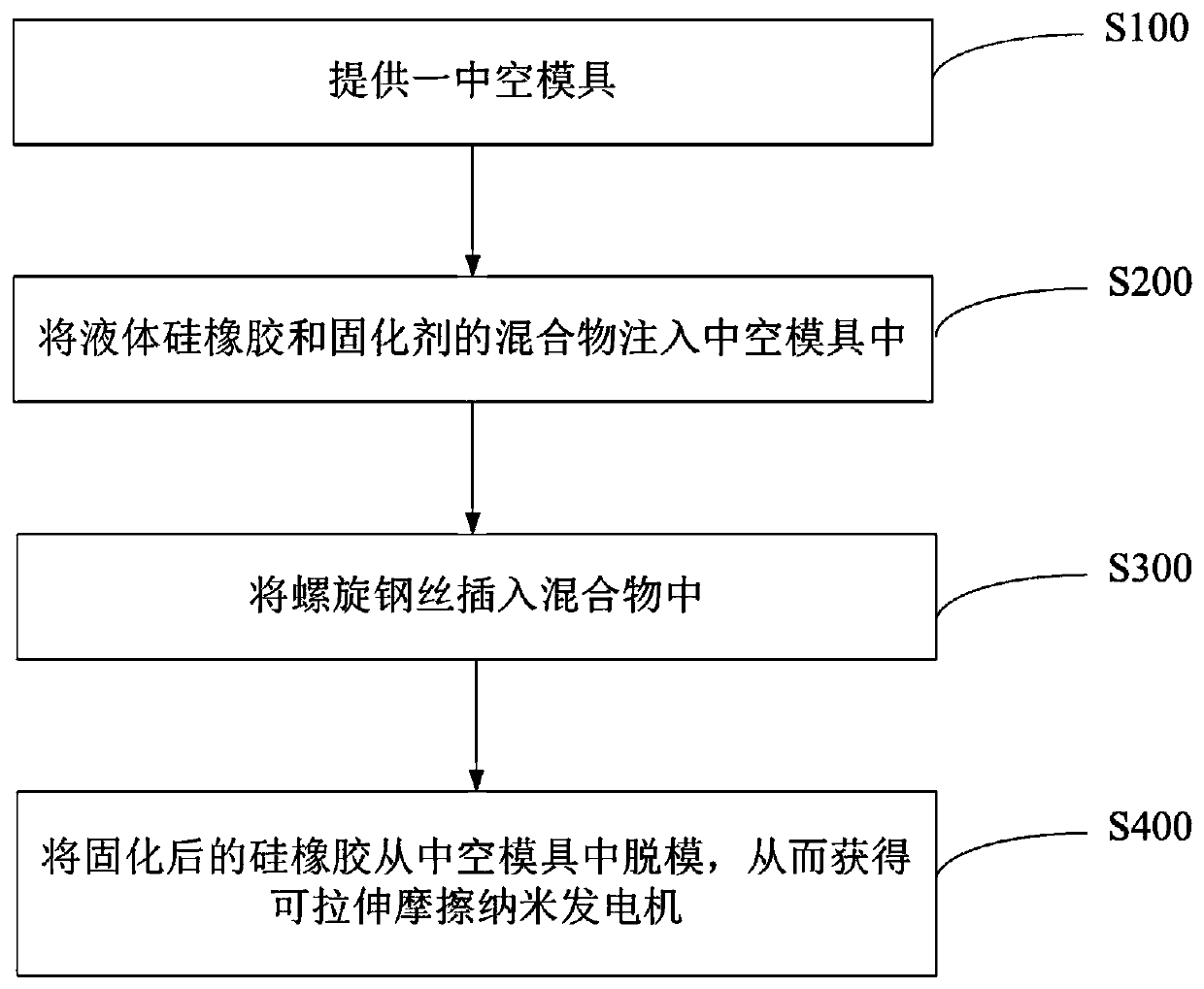

Method used

Image

Examples

Embodiment Construction

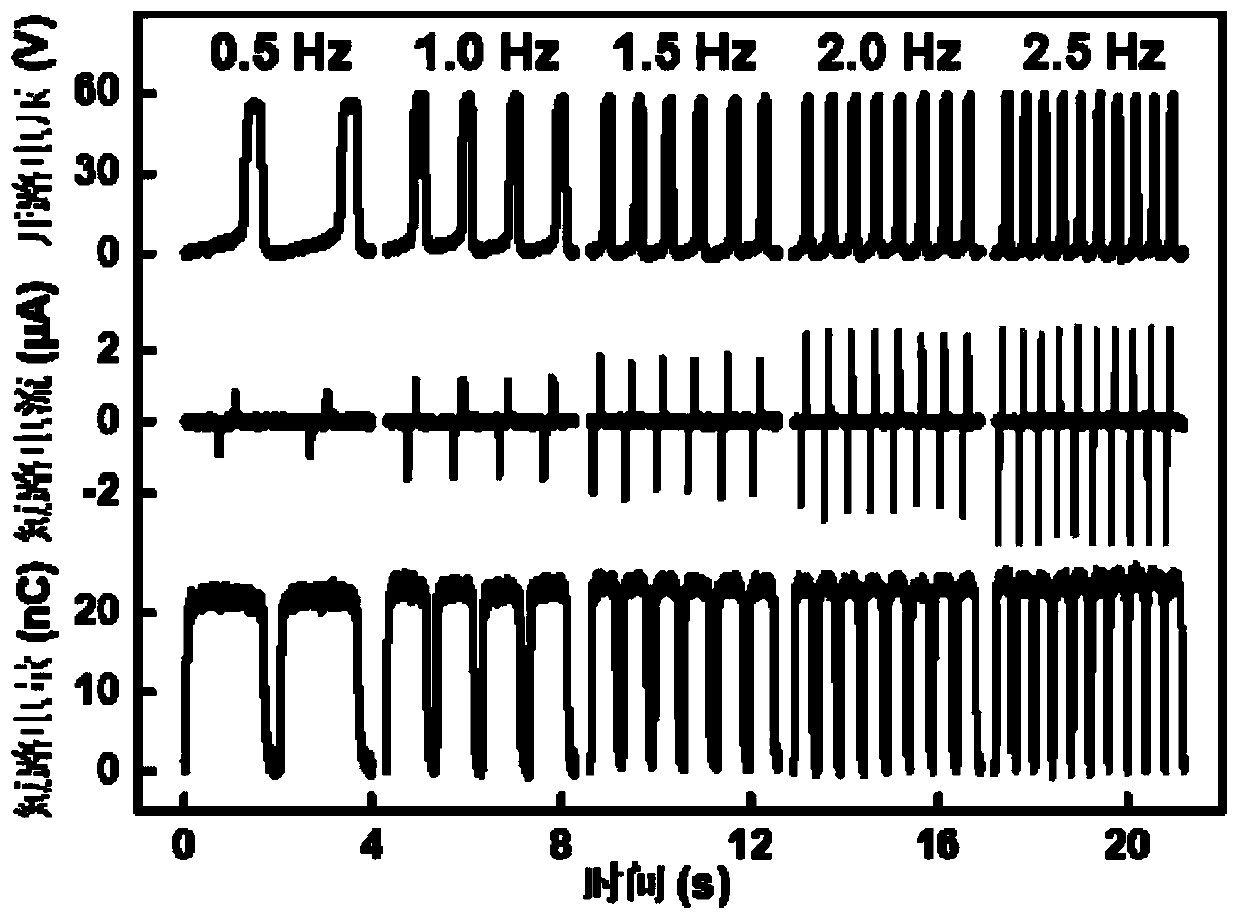

[0040] figure 1 A schematic structural diagram of a stretchable triboelectric nanogenerator in a single-electrode mode according to an embodiment of the present invention is shown. like figure 1 As shown, the stretchable triboelectric nanogenerator includes silicone rubber 11 and helical steel wire 12 . Silicone rubber 11 is used as a friction material. The spiral steel wire 12 as an electrode material is formed in the silicone rubber 11 and extends from one end of the silicone rubber 11 . The helical wire 12 is configured to match the Young's modulus of the silicone rubber 11 . The structure of the stretchable triboelectric nanogenerator is fibrous.

[0041] When the skin comes into contact with the silicone rubber, a negative triboelectric charge remains on the surface of the silicone rubber and creates a positive charge on the skin. When separated from the skin, electrons flow from the conductive helical wire 12 to the ground under short-circuit conditions, and a posit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com