A kind of preparation method of bismuth oxygen sulfur two-dimensional material and photodetector

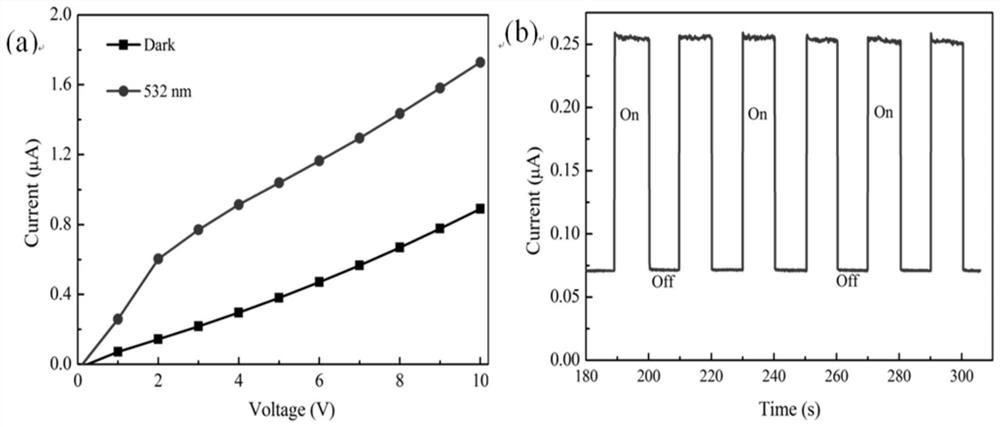

A photodetector, two-dimensional material technology, applied in circuits, electrical components, semiconductor devices, etc., can solve the problems of high reaction temperature, poor chemical stability and electron mobility, harsh preparation conditions, etc., and achieve good application prospects, The effect of good photodetection performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The invention discloses a bismuth oxysulfide (Bi 2 o 2 S) the preparation method of two-dimensional material, comprises the steps:

[0027] Step 1: Disperse thiourea in deionized water, stir magnetically until completely dissolved, then add ammonium bismuth citrate;

[0028] Step 2: Stir the solution in step 1 evenly, then add potassium hydroxide at a concentration of 0.2 to 4.0 mol / L, and stir at room temperature for 1 to 3 hours;

[0029] Step 3: Transfer the stirred mixed solution to a high-temperature-resistant p-polyphenylene (PPL) reactor, and keep it warm at 25 to 220°C for 3 to 48 hours; Step 3 uses a one-step hydrothermal method for the preparation of materials ;

[0030] Step 4: Wash the product alternately with two solvents of deionized water or absolute ethanol, and centrifuge at a speed of 3000 to 10000 rpm for 3 to 8 minutes, and alternately wash 2 to 6 times), thereby preparing Bi 2 o 2 S two-dimensional material;

[0031] As a preferred embodiment,...

Embodiment 1

[0039] Example 1: 12 mmol (5.821 g) of bismuth nitrate pentahydrate was weighed and dissolved in 50 ml of deionized water, and magnetically stirred at room temperature until uniformly mixed. Then add 6mmol (0.457g) of thiourea, and continue to stir until the solution is evenly mixed. Then add a certain concentration of KOH, continue to stir until the solution is evenly mixed, then transfer the above solution to the lining of a 100ml reactor, add deionized water to adjust the solution to 60% of the dissolved volume of the reactor, and finally put the reactor into oven. After the experiment, the obtained precipitate was alternately centrifuged with absolute ethanol and deionized water for 6 times, and centrifuged at 4500 rpm for 5 minutes. After repeated 6 times of cleaning, it was dried in an oven and ground into powder. It can be found that using bismuth nitrate pentahydrate as bismuth source, the prepared Bi 2 o 2 The morphology of the S product is long-sided, but the late...

Embodiment 2

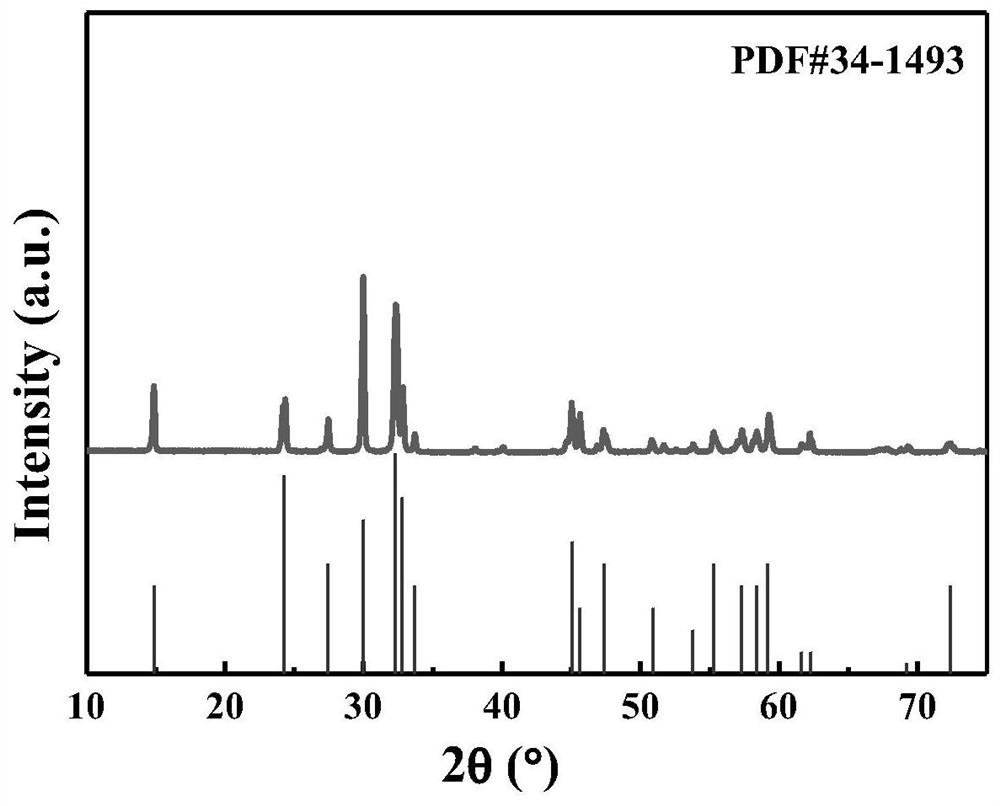

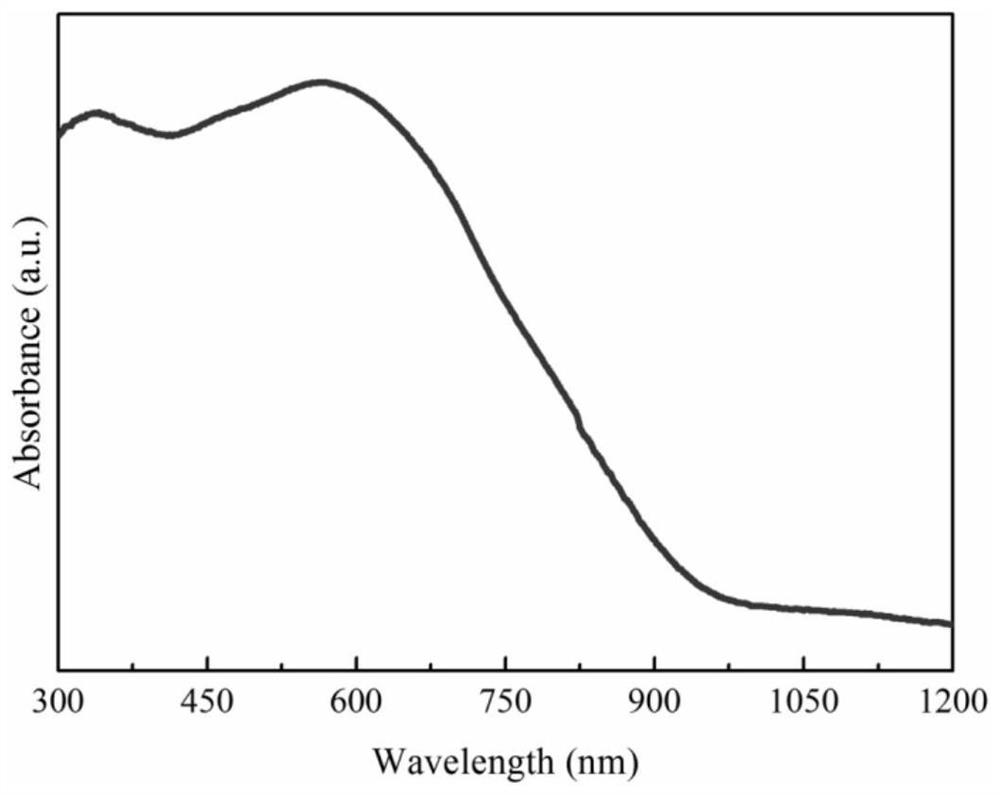

[0040] Example 2: 6 mmol (0.457 g) of thiourea was weighed and dissolved in 50 ml of deionized water, and magnetically stirred at room temperature until uniformly mixed. Then add 12mmol (5.426g) of ammonium bismuth citrate, and continue to stir until the solution is evenly mixed. Then add a certain concentration of KOH, continue to stir until the solution is evenly mixed, then transfer the above solution to the lining of a 100ml reactor, add deionized water to adjust the solution to 60% of the dissolved volume of the reactor, and finally put the reactor into oven. After the experiment, the obtained precipitate was alternately centrifuged with absolute ethanol and deionized water for 6 times, and centrifuged at 4500 rpm for 5 minutes. After repeated 6 times of cleaning, it was dried in an oven and ground into powder. figure 1 It is the XRD pattern that the embodiment of the present invention provides. It can be found that when bismuth ammonium citrate is used as the bismuth s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com