High-capacity mobile heat source and operation method thereof

A large-capacity, heat source technology, applied in water heaters, fluid heaters, lighting and heating equipment, etc., can solve problems such as pollution, smoke emissions, and unsustainable heating, and achieve reasonable equipment layout and low nitrogen oxide emissions , the effect of small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

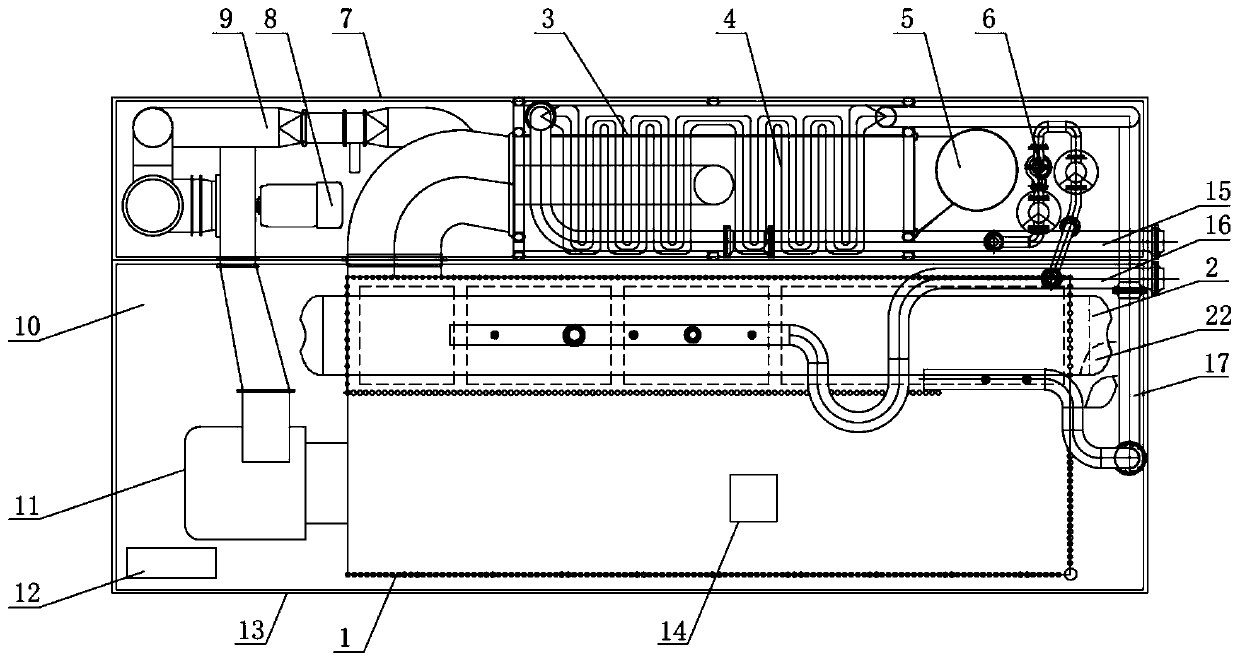

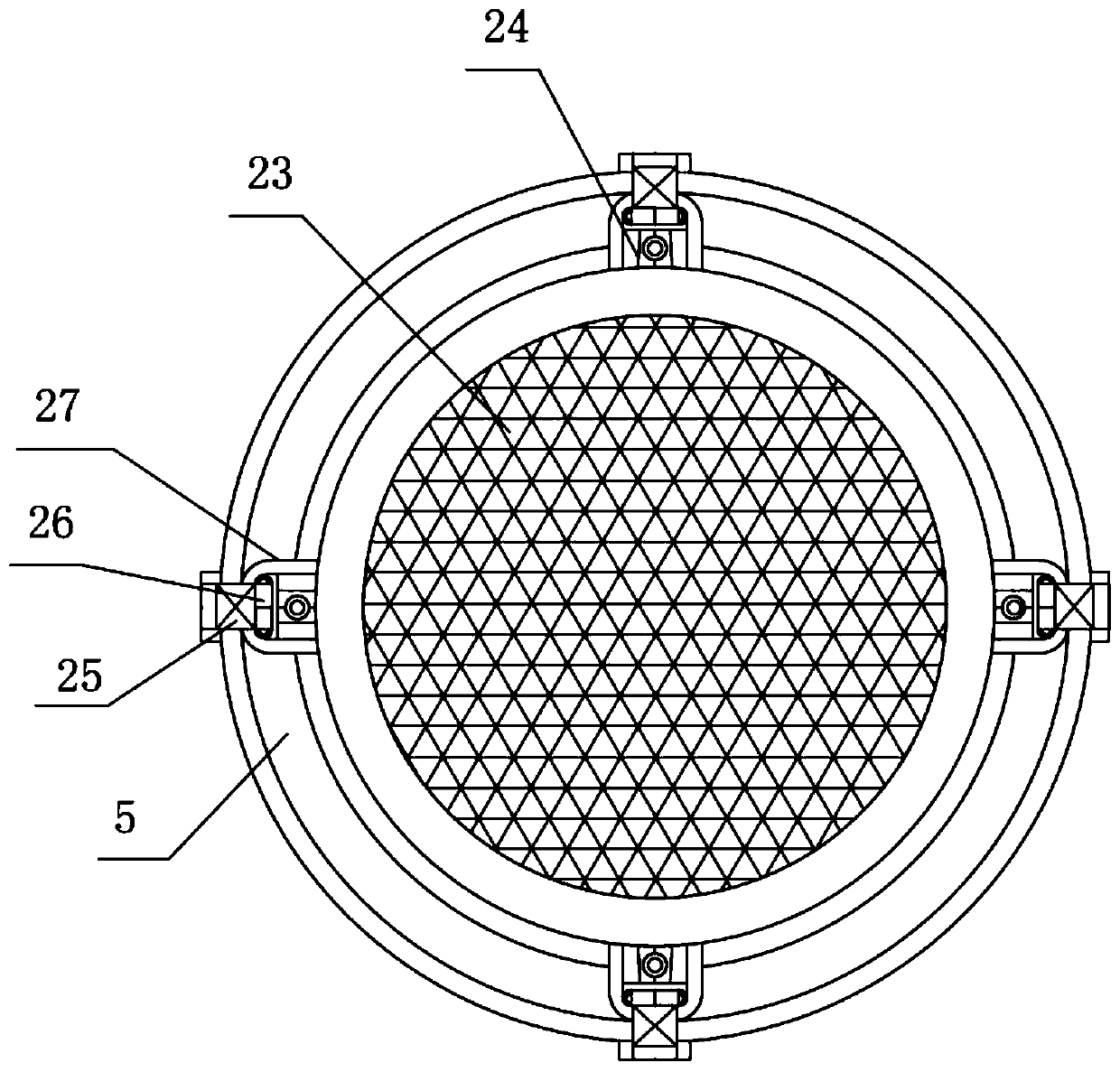

[0027] like figure 1 and figure 2 As shown, the large-capacity mobile heat source of this embodiment includes a boiler container 13, which is provided with a D-shaped furnace 1, and a power cabinet 10 is installed in the boiler container 13 at one end of the D-shaped furnace 1, and a power cabinet 10 is installed in the power cabinet 10. There is a burner 11 installed on the front wall of the D-type furnace 1, a membrane-type water-cooled wall tube (not shown in the figure) is laid on the inner wall of the D-type furnace 1, and the upper drum 2 is connected to one end of the D-type furnace 1 and installed above the The upper drum 2 connected by the water wall tube, the water wall tube is connected to the lower drum 22 through the convection tube bundle (not shown in the figure), and the lower drum 22 is connected with an outlet pipeline ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com