Agriculture and forestry biomass gasification power generation method

A biomass, agriculture and forestry technology, applied in chemical instruments and methods, granular/powder fuel gasification, physical/chemical process catalysts, etc. The effect of reducing environmental pollution and improving the utilization rate of calorific value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

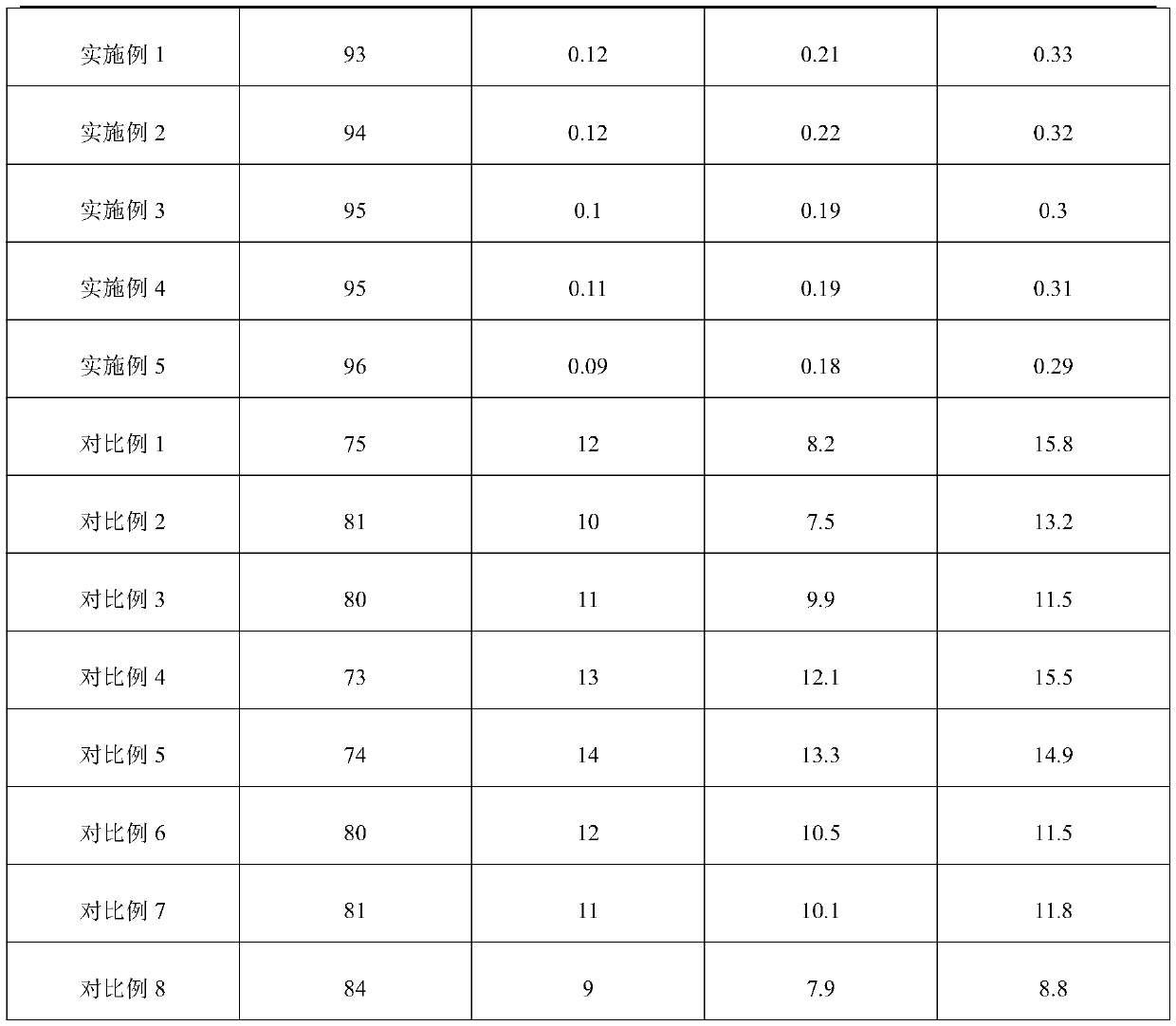

Embodiment 1

[0030] A method for generating electricity by gasifying agricultural and forestry biomass, which mainly includes three steps: pretreatment of agricultural and forestry biomass, gasification and catalytic cracking to generate combustion gas, and utilization of combustion gas to generate electricity. The diameter is 30 μm and dried until the moisture content is 10% to obtain raw materials; the specific method of gasification and catalytic cracking is: after pretreatment, the agricultural and forestry biomass is gasified with a gasification agent in a fluidized bed gasification furnace, Cracking produces mixed cracking gas under the effect of catalyzer then, and the consumption of described catalyzer is 3% of raw material weight, and catalyzer obtains by following preparation method:

[0031] (A) magnesium carbonate and zinc carbonate are mixed uniformly to obtain mixed powder;

[0032] (B) adding the mixed powder into the manganese acetate aqueous solution, stirring evenly to ob...

Embodiment 2

[0044] A method for generating electricity by gasifying agricultural and forestry biomass, which mainly includes three steps: pretreatment of agricultural and forestry biomass, gasification and catalytic cracking to generate combustion gas, and utilization of combustion gas to generate electricity. 50 μm in diameter and dried until the moisture weight content is 12%, to obtain raw materials; the specific method of gasification and catalytic cracking is: after pretreatment, the agricultural and forestry biomass is gasified with a gasification agent in a fluidized bed gasifier, Cracking produces mixed cracking gas under the effect of catalyzer then, and the consumption of described catalyzer is 4% of raw material weight, and catalyzer obtains by following preparation method:

[0045] (A) magnesium carbonate and zinc carbonate are mixed uniformly to obtain mixed powder;

[0046] (B) adding the mixed powder into the manganese acetate aqueous solution, stirring evenly to obtain the...

Embodiment 3

[0058] A method for generating electricity by gasifying agricultural and forestry biomass, which mainly includes three steps: pretreatment of agricultural and forestry biomass, gasification and catalytic cracking to generate combustion gas, and utilization of combustion gas to generate electricity. The diameter is 30 μm and dried until the moisture weight content is 12% to obtain raw materials; the specific method of gasification and catalytic cracking is: after pretreatment, the agricultural and forestry biomass is gasified with a gasification agent in a fluidized bed gasifier, Cracking produces mixed cracking gas under the effect of catalyzer then, and the consumption of described catalyzer is 3% of raw material weight, and catalyzer obtains by following preparation method:

[0059] (A) magnesium carbonate and zinc carbonate are mixed uniformly to obtain mixed powder;

[0060] (B) adding the mixed powder into the manganese acetate aqueous solution, stirring evenly to obtain ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com