Size-stable seawater impermeable material and preparation method thereof

A dimensionally stable, waterproofing membrane technology, applied in the field of seawater anti-seepage waterproofing membrane and its preparation, can solve the problems affecting the scope of application, difficulty in simultaneously improving the dimensional stability and mechanical properties of PE-HD, poor stability of the waterproofing membrane, etc. , to achieve the effect of reducing the impact of construction errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

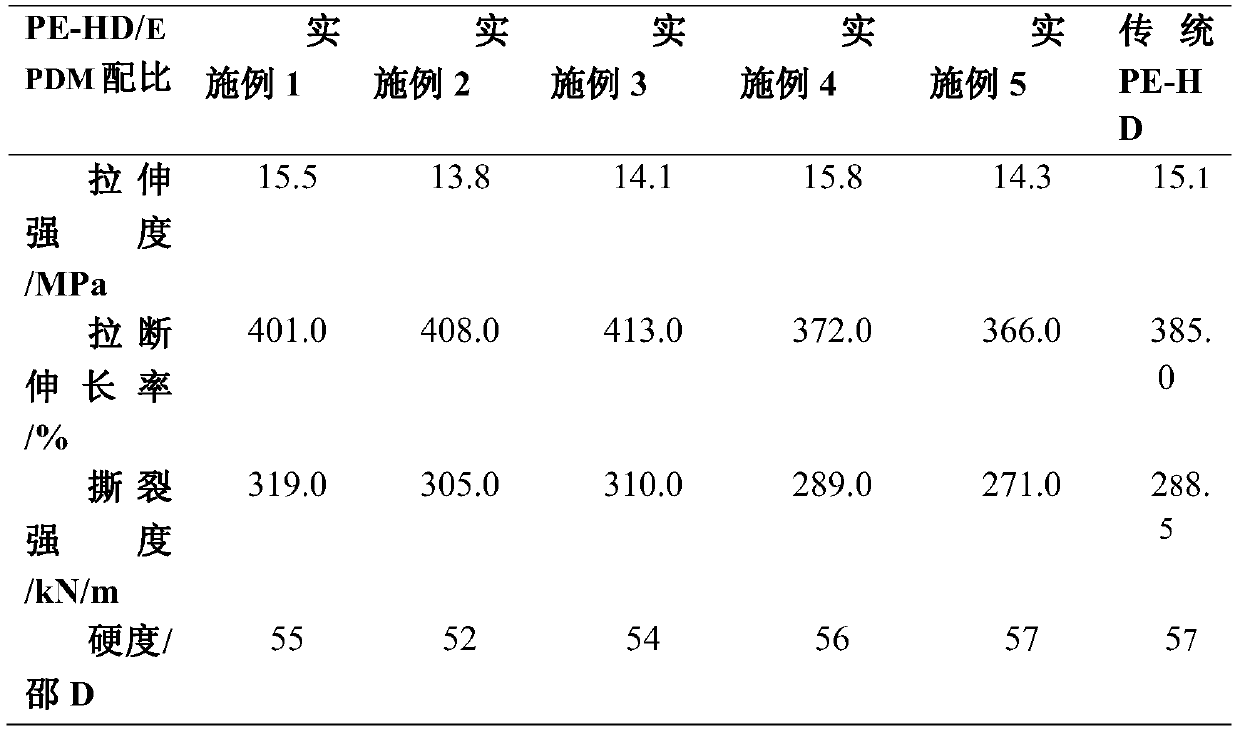

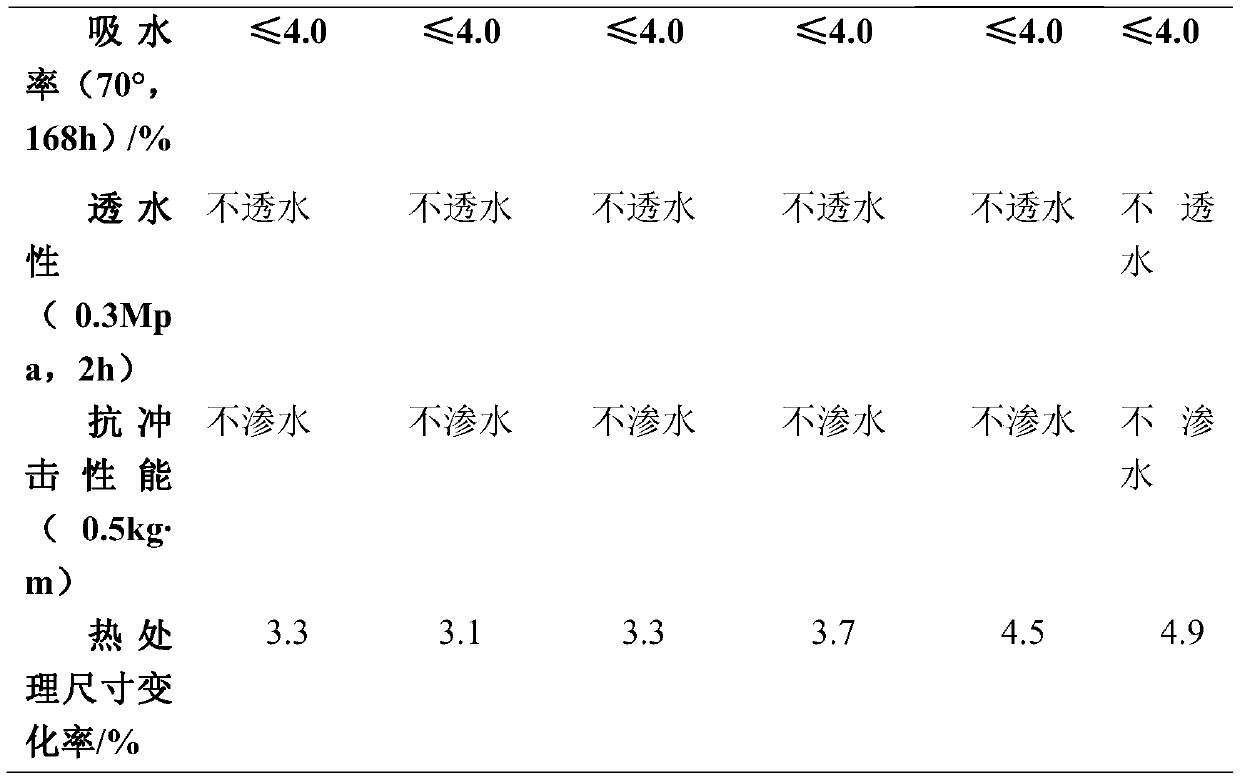

Examples

Embodiment 1

[0025] Example 1: PE-HD / EPDM rubber powder is combined to prepare a waterproof membrane with good dimensional stability

[0026] The produced waterproof membrane contains the following components (wt.%): PE-HD:6898, Sinopec Yangzi Petrochemical Co., Ltd.; EPDM rubber 3960Q, Lanxess, Germany; PE-HD-g-MAH, self-made; white Carbon black, Degussa; ethylene vinyl acetate, commercially available general product; softener MESAMOLL, commercially available general product. The ratio is (parts by weight): 60:15:1.5:20:1:2.5. The specific production steps are as follows:

[0027] 1. Preparation of PE-HD-g-MAH. First, add 100 parts by mass of PE-HD, 3 parts by mass of MAH and 100 parts by mass of solvent acetone into a four-necked flask, gradually increase the temperature and heat to 115° C., and cool to room temperature naturally after the solvent. Then add 3 parts by mass of dodecylbenzenesulfonic acid (interface agent C18H30O3S), and heat up again, and add 0.3 parts by mass of initi...

Embodiment 2

[0030] Example 2: PE-HD / EPDM rubber is used to prepare a waterproof membrane with good dimensional stability

[0031] PE-HD: 6898; EPDM rubber; PE-HD-g-MAH; All the other are the same as in Example 1.

Embodiment 3

[0032] Embodiment 3: PE-HD / EPDM rubber is used to prepare waterproof membrane with good dimensional stability

[0033] PE-HD: 6898; EPDM rubber; PE-HD-g-MAH; white carbon black; ethylene vinyl acetate; All the other are identical with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com