Free radical photopolymerization dark curing initiation system and preparation method thereof

A technology of initiation system and photopolymerization, which is applied in the field of photopolymerization curing initiation system, free radical photopolymerization dark curing initiation system and its preparation field, can solve the problems of less heat release during initiation polymerization, short illumination time, low utilization efficiency, etc. Achieve the effect of high conversion rate of initiation polymerization, short irradiation time, and less heat of polymerization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

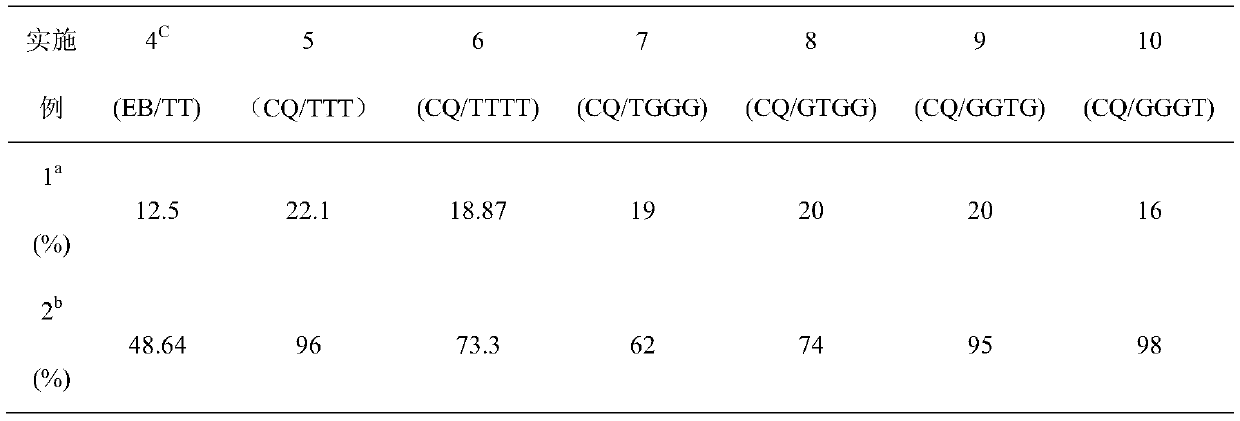

Embodiment 1

[0035] A free radical photopolymerization dark curing initiation system, its components are as follows:

[0036] The first component: camphorquinone (CQ) 0.5%,

[0037] The second component: dimer tyrosine (TT) 0.5%,

[0038] Prepare the dark curing initiation system according to the above-mentioned proportion, and based on the weight of the dark curing reaction liquid as 100%, add the dark curing initiation system to an aqueous solution containing 30% acrylamide and mix thoroughly to obtain a transparent and clear dark curing reaction liquid. That is, the composition of the dark curing reaction liquid is: 0.5% camphorquinone, 0.5% dimer tyrosine, and 99% aqueous solution containing 30% acrylamide.

[0039] Photopolymerization reaction: The prepared dark curing reaction solution is placed in a sealed transparent glass test tube, filled with nitrogen and deoxygenated for 10 minutes, and irradiated under a 150W metal halide lamp for 2 minutes, with a light intensity of about 20...

Embodiment 2

[0041] A free radical photopolymerization dark curing initiation system, its components are as follows:

[0042] The first component: riboflavin (RF) 0.5%,

[0043] The second component: dimer tyrosine (TT) 0.5%,

[0044] Prepare the dark curing initiation system according to the above-mentioned proportion, taking the weight of the dark curing reaction solution as 100%. Add the dark curing initiation system into the aqueous solution containing 30% acrylamide and mix thoroughly to obtain a transparent and clear dark curing reaction solution. That is, the composition of the dark curing reaction liquid is: 0.5% riboflavin, 0.5% dimer tyrosine, and 99% aqueous solution containing 30% acrylamide.

[0045] Photopolymerization reaction: The prepared dark curing reaction solution is placed in a sealed transparent glass test tube, filled with nitrogen and deoxygenated for 10 minutes, placed under a 150W metal halide lamp for 5 minutes, and the light intensity is about 20mW / cm 2 . T...

Embodiment 3

[0047] A free radical photopolymerization dark curing initiation system, its components are as follows:

[0048] The first component: tetraiodofluorescein disodium (EB) 0.01%,

[0049] The second component: dimer tyrosine (TT) 0.5%,

[0050] Prepare the dark curing initiation system according to the above-mentioned proportion, taking the weight of the dark curing reaction solution as 100%. Add the dark curing initiation system into the aqueous solution containing 30% acrylamide and mix thoroughly to obtain a transparent and clear dark curing reaction solution. That is, the composition of the dark curing reaction solution is: 0.01% of disodium tetraiodofluorescein, 0.5% of dimer tyrosine, and 99% of an aqueous solution containing 30% of acrylamide.

[0051] Photopolymerization reaction: The prepared dark curing reaction solution is placed in a sealed transparent glass test tube, filled with nitrogen and deoxygenated for 10 minutes, placed under a 150W metal halide lamp for 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com